Supply Chain Management

The Kyocera Group has established a "Basic Policy on Purchasing" to ensure that transactions with our business associates are carried out fairly and transparently. We work together as a team with associates to implement fair business practices.

Policy Related to Purchasing Activities

The Management Rationale of the Kyocera Group is: "To provide opportunities for the material and intellectual growth of all our employees, and through our joint efforts, contribute to the advancement of society and humankind." We view our commitment to fairness in supply chains as a key requirement toward fulfilling this ideal. The Kyocera Group believes that mutual prosperity is possible only if all supply-chain stakeholders -- including development, production, sales, and service enterprises -- work together to address societal needs. This demands continuous engagement with business partners through mutual trust. In December 2020, Kyocera announced its "Declaration of Partnership Building" to promote deeper collaboration with existing suppliers and other businesses seeking to create new value.

The Kyocera Group revised its Declaration of Partnership Building in March 2024 to include all suppliers.

Basic Policy on Purchasing

At the Kyocera Group established the Basic Policy on Purchasing. Under this policy, we conduct various surveys on corporate overviews and sustainability to evaluate and select our business partners fairly.

Basic Policy on Purchasing

Significance and Purpose of the Procurement Department

Through our procurement operations, we will contribute to value creation and business development, pursue our work with sincerity, and by living in harmony with our suppliers, we will hone our character and earn the trust of society. We, the Procurement Department, aim to be a trusted the Procurement Department with value through constant gratitude, humble reflection, and further efforts.

Supplier Selection Policy

We select our suppliers based on the following policy.

- To understand our basic philosophy.

- Management's own thinking and management philosophy must be convincing.

- The company must be appropriate and stable in terms of size and finances, aiming to improve its management, technical and manufacturing capabilities.

- Overall excellence in quality, price, delivery time, and service responsiveness.

- To be active in global environmental conservation activities.

- Comply with the Kyocera Group Guidelines for Supply Chain Code of Conduct in the Supply Chain.

Kyocera Group Sustainability Guidelines

The Kyocera Group has established "Kyocera Group Sustainability Guidelines" ("Kyocera Group Supply Chain Code of Conduct") in accordance with the guidelines of Responsible Business Alliance (RBA) to appropriately address important sustainability issues throughout our supply chain. We ask our business partners to sign a basic transaction agreement that includes provisions for compliance with these guidelines.

Sustainability Guidelines

(Kyocera Group

Supply Chain Code of Conduct)

Promoting Sustainability in the Supply Chain

As the member of the Responsible Business Alliance (RBA), the Kyocera Group complies with the RBA Code of Conduct and works with suppliers to promote sustainability activities in order to fulfill its social responsibilities.

Sustainable Procurement Initiatives

Designation of Key Suppliers

The Kyocera Group designates our top 80% of suppliers in terms of purchase amount in the previous fiscal year as key suppliers, focusing on suppliers who supply us with important raw materials, suppliers with large transaction amounts, and suppliers who cannot be replaced, including suppliers who attended the supplier reception. We ask these suppliers to respond to our supply chain survey.

Supplier Survey on Sustainability Activities

Based on the "Kyocera Group Supply Chain Code of Conduct", we conduct surveys of our suppliers' compliance status every year within the Supply Chain, including overseas suppliers.

Companies Surveyed

The survey covers suppliers identified as key suppliers.

| Type of supplier | Total number of suppliers | Number of key suppliers | Number of key suppliers assessed in the last three years | Percentage of suppliers assessed in the last three years | Target (FY2025) (Percentage of total business partners) | Result |

|---|---|---|---|---|---|---|

| Critical supplier for direct delivery | 4,966 | 341 | 345 | 80.0%(transaction amount) 6.0%(number of companies) |

Target:80%(transaction amount) Target:6%(number of companies) |

341 companies |

Evaluation Items

The Kyocera Group conducts survey on the following key ESG-focus categories: human rights and labor, the environment, health and safety, fair trade and ethics, quality and safety, business continuity plans (BCPs), information security and responsible mineral sourcing, and conducts due diligence in answer to the responses as described below.

Evaluation Criteria

Activities with an overall score of 20% or less are considered "inadequate" and field audits are subsequently performed to request improvements until an overall score of at least 20% is reached. Activities with a score in the 20% to 60% range are considered "slightly inadequate" and feedback is provided to prompt improvements until a score of at least 60% is reached. Suppliers capable of responding to the surveys and addressing points raised and requests for remedial action are deemed to possess an ability development program.

| Rank | Score | Status of Efforts |

|---|---|---|

| A | 80% or more | Very good |

| B | 60% or more | Good |

| C | 40% or more | Somewhat inadequate |

| D | a score of less than 20% | Insufficient |

Evaluation Results

In FY2025, 341 suppliers responded to the survey form, of which 47% were rated A. In addition, 6 companies that have been ranked D are working on corrective measures.

Risk Clarification

As a result of surveys conducted on human rights and labor, environment, health and safety, fair trade and ethics, quality and safety, business continuity plan (BCP), and information security, suppliers whose efforts are judged to be insufficient are considered high risk.

For those suppliers that are determined to be high-risk, we provide feedback on the survey results and request them to make improvements by explaining their requirements using our guidelines. If we determine that improvements have not progressed, we continue our dialogue by visiting them to discuss countermeasures. In 2024, the 6 companies that were requested to take corrective measures were classified as high risk, and we will continue to monitor their effectiveness.

| Type of supplier | Total number of suppliers | Number of key suppliers | Number of suppliers classified as high risk | Percentage of total suppliers classified as high-risk |

|---|---|---|---|---|

| Critical supplier for direct delivery | 4,966 | 341 | 6 | 1.78% |

In addition, Kyocera has confirmed that the rate of high-risk suppliers with respect to the items of "human rights and labor" and "ethics," which Kyocera has selected as important items, is zero in both cases.

| KPI | Targeted figures and year of achievement | Result | |

|---|---|---|---|

| FY2025 | |||

| Percentage of high-risk suppliers on human rights and labor items | Target value: 0%. Target year for achievement: FY2025 |

0% | |

| Percentage of high-risk suppliers on ethics items | Target value: 0%. Target year: FY2025 |

0% | |

In regard to other items shown below, no issues were found through the survey.

- Workers that fall under the category of child labor

- Workers who could not receive full amount of wages directly on time

- Workers whose ID cards were taken away, or whose freedom of movement was limited

- Workers whose freedom of association or collective bargaining was limited

- Female workers who were discriminated against or forced to work under unfair working conditions

- Workers whose health and safety were damaged

- Workers who labored for excessively long working hours

Request for Cooperation in Ongoing Risk Reduction

Kyocera put out a request to all suppliers to implement improvements with the goal of eliminating risk. All suppliers responded that they were able to make improvements. The same survey, with the same goal, will be carried out again in FY2025. The list of suppliers participating in the survey is reviewed every year, and efforts are made to ensure equal application of judgment criteria.

Percentage of Suppliers with Improved Ratings

| Measure | Percentage |

|---|---|

| Percentage of suppliers with high sustainability risk (as defined in "Risk Exposure") that have corrective action plans: | 100% |

| Percentage of suppliers with corrective action plans that have improved their ESG performance within 12 months of the plan's launch: | 100% |

Holding Seminars and social gatherings with suppliers

The Kyocera Group regularly holds supplier seminars with business associates to help them better understand the management and business policies of the Kyocera Group and to build further partnerships. The 2025 event was held in February with 272 people from 232 companies in attendance. We also recognized business partners who have exhibited particular excellence in quality, price, and delivery times in transactions during the year.

Supply Chain BCP Survey

The Kyocera Group's policy is to achieve prompt restoration and resumption of operations even if the supply of products and services is interrupted due to a disaster, etc. We survey our suppliers on the status of their Business Continuity Plan (BCP) and request them to promote BCP activities. We explain the importance of BCP to new suppliers of important raw materials and parts and ask them to strengthen their BCP measures. We also confirm the improvement status of suppliers whose efforts were insufficient in the previous year's survey.

We will continue our efforts to promote and disseminate the BCP so that our suppliers can promote their initiatives.

Commitment to Responsible Mineral Procurement

The Kyocera Group complies with laws and regulations such as the U.S. Financial Regulatory Reform Act (Dodd-Frank Act), which was enacted because mineral resources mined in the Democratic Republic of the Congo and adjacent countries are a source of funding for armed groups that are causing human rights abuses, and the EU Conflict Minerals Regulation.

In addition, the OECD requires all companies to "responsibly procure minerals" based on the "Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict and High-Risk Areas" (OECD Guidance). The Kyocera Group has established a "Responsible Minerals Procurement Policy" based on the OECD Guidance and is working to mitigate risks and make supply chains more transparent by examining supply chains for the presence of risks, such as conflicts and human rights violations, assessing risks, and taking corrective actions.

Kyocera Group Responsible Mineral Procurement Policy

The Kyocera Group has a policy of "not purchasing materials or products that use conflict minerals that fund armed groups or other metals that pose a risk of human rights abuses," including gold, tin, tantalum, tungsten, cobalt, Natural mica, and other minerals. (Revised in June 2024)

For example, Kyocera's ceramic packages and electronic components use gold plating for circuit formation and connection terminals and require tin for solder. Tantalum is used in capacitors to increase their storage capacity, and tungsten is used to strengthen the hardness of cutting tools. As described here, Kyocera's products rely on a broad range of minerals as raw materials. We consider it absolutely essential that requirements on responsible procurement go beyond the letter of the law to fully facilitate corporate sustainability efforts and global sustainability . The Kyocera Group conducts investigative practices based on the RMAP*1 promoted by the RMI*2.

- Responsible Mineral Assurance Process

- Responsible Mineral Initiative

Responsible Mineral Procurement Response System

The Kyocera Group has established the "Kyocera Group Conflict Minerals Handling Regulations" to ensure responsible mineral procurement. Investigations to determine whether we are procuring minerals without risk are conducted in accordance with the system, and due diligence is conducted on the status and results. We also educate Kyocera Group companies on rules and policies related to conflict minerals and promote appropriate Group-wide initiatives regarding conflict minerals. Furthermore, in order to recognize risks in responsible mineral procurement at an early stage, we have established a system to promptly respond to complaints and reports on conflict minerals collected through the contact points with stakeholders, the contact point in the procurement department, and the internal reporting system.

Efforts in accordance with OECD Due Diligence Guidance

The Kyocera Group's investigations for responsible mineral procurement follow a system and procedures that comply with the five-step framework set forth in the OECD Due Diligence Guidance. Specifically, Kyocera conducts investigative practices based on the MAP*1 promoted by the RMI*2 and evaluates all risks, including human rights violations, as stipulated in Annex II of the guidance. In addition, to preparing for a wide variety of human rights violation risks and other broad-reaching ESG risks, we are working to collect information on human rights regulations in each country as well as requests from customers and NGOs. We are strengthening our monitoring of sustainability initiatives as well as laws, for example by responding to investigations on minerals with high human rights violation risks such as cobalt. The OECD Due Diligence Guidance for Minerals requires the five-step framework for supply chains, and the Kyocera Group has complied with all five steps.

Actions for Business Partners and Survey Results

The Kyocera Group is strengthening our internal control system by holding due diligence training sessions for personnel in charge at each Kyocera Group company in the U.S., China, Vietnam, and Thailand. In addition, The Kyocera Group promotes collaboration and cooperation with industry associations as a means of cooperating with external parties regarding responsible mineral sourcing. Specifically, Kyocera has participated as a key member of the "Responsible Minerals Procurement Study Group" established within the Japan Electronics and Information Technology Industries Association (JEITA) since its inception in order to respond to regulations related to Section 1502 of the U.S. Financial Regulatory Reform Act and others. We have been taking the lead in cooperating with the "Responsible Mineral Procurement Study Group" in identifying and addressing issues in the study and in conducting the study briefing sessions.

Moreover, Kyocera conducted a survey of our business partners using the Conflict Minerals Reporting Template (CMRT) prepared by the Responsible Minerals Initiative (RMI), an international organization dealing with conflict mineral issues. From FY2019, the Due Diligence based on Annex II of the OECD Guidance has been conducted. We checked the smelters/refineries listed in the CMRT provided by our suppliers against the list disclosed in the RMI. As a result, we sent a Risky Smelter Report to business partners who had some problems that needed addressing in order to raise their attention, and we pressed supply chains for smelters/refineries to acquire Conformant certification and hold consultation meetings to respond to issues and questions that our business partners have. We will continue to request said activities until our goal of conflict-free minerals procurement is achieved.

Results that we checked the smelters/refineries listed in the CMRT provided by our suppliers against the list disclosed in the RMI.

| Gold | Tantalum | Tin | Tungsten | Total | |

|---|---|---|---|---|---|

| Number of refineries/smelters< | 182 | 46 | 76 | 58 | 362 |

| Number of refineries/smelters validated as CFS* | 93 | 40 | 55 | 37 | 225 |

| Number of refineries/smelters considered as non-CFS (including those with certification pending) | 89 | 6 | 21 | 21 | 137 |

Smelters/refineries that have been certified by a third party as not involved in conflicts and not having human rights violations or other problems.

Customer EMRT Survey

Kyocera Group conducts surveys for cobalt every year since 2019, which is increasingly requested by our customers. From FY2023, we surveyed using the new Extended Material Reporting Template (EMRT) published by RMI, further expanding the target minerals and target suppliers. The response rate was 94.0% for the EMRT survey and 96.4% for the CMRT survey, indicating a high degree of understanding and interest in the supply chain.

EMRT Survey Results for FY2025

| mineral | registered facility | conformant authentication | Uncertified | conformance rate |

|---|---|---|---|---|

| Cobalt | 96 | 53 | 43 | 55.21% |

| Natural mica | 29 | 2 | 27 | 6.90% |

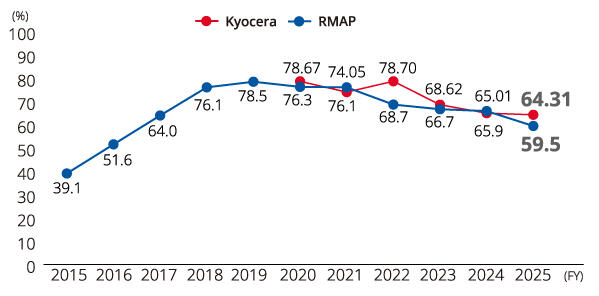

No smelters/refineries were identified as at risk. Conversely, the rate of smelters/refineries acquiring an RMAP Conformant certification has been trending downwards in recent years for the 3TG minerals (tantalum, tin, tungsten, and gold), and proportionally, the usage rate of smelters/refineries certified as risk-free in Kyocera is also on a downward trend. We will look to requesting business partners to review the list of smelting plants while lobbying smelting plants to undergo audits through the efforts of the JEITA Responsible Mineral Trade Working Group. In addition, we have established and are managing the following KPIs so that we can report these activities in a more quantifiable manner.

Conformant smelter/refineries Ratio

| KPI | Targeted figures and year of achievement | FY2025 |

|---|---|---|

| Percentage of conformant smelter/refineries usage that has been evaluated for conflict-affected and high-risk areas (CAHRAs*) and certified as risk-free | Target value: 80%. Target year for achievement: FY2026 |

64.3% |

A high-risk area for conflict or human rights violations, etc., as defined in the OECD Due Diligence Guidance.

Participation in JEITA

Kyocera also participates in JEITA's CSR Committee with the aim of strengthening sustainability activities throughout the supply chain. In addition, we encourage the participation of related business partners, Kyocera employees, and all other stakeholders at JEITA-held seminars, which serve as ESG training opportunities. The impact of these opportunities is quantitatively verified based on follow-up surveys and evaluations of the current state of affairs based on regular sustainability surveys and responsible minerals procurement surveys.

Membership in the RBA

In 2022, Kyocera joined the Responsible Business Alliance (RBA), a non-profit business alliance composed of electronics, retail, automotive, toy, and other related industries with the goal of supporting the rights and well-being of workers and communities affected by global supply chains. As a global business enterprise, Kyocera fully supports the vision and mission of the RBA and is committed to improving efforts to build more a sustainable supply chain.

Human rights due diligence initiatives for the Kyocera supply chain

The Kyocera Group conducts "Human Rights Due Diligence" as outlined in the Kyocera Group Human Rights Policy. In order to comply with the Kyocera Group Human Rights Policy, a human rights due diligence framework for the supply chain was developed and commenced operation in line with the UN's Guiding Principles on Business and Human Rights.

Assessment of the Impact of Salient Human Rights Issues (FY2025 to FY2026)

In FY2025, to understand and evaluate the current and potential impact of identified salient human rights issues on human rights holders, an in-depth survey of salient human rights issues was conducted at 293 domestic suppliers. We are planning to conduct on-site surveys in FY2026 to better understand the actual situation regarding concerns identified about domestic suppliers through the results of this questionnaire.

Ⅰ. Questionnaire Survey

A survey was conducted of 293 domestic suppliers of Kyocera.

[Survey results]

The survey response rate for domestic suppliers was 74.4% (218 companies). We will continue to analyze these responses, and we are planning to conduct on-site surveys in FY2026 to obtain more information from suppliers who have responded to concerns about risks so that we might increase our understanding of the actual situation.

| Subject domestic supplier | Suppliers responding | Survey response rate |

|---|---|---|

| 293 | 218 | 74.4% |

Assessment of the Impact of Salient Human Rights Issues (FY2024 to FY2025)

To understand and evaluate the current and potential impact of identified salient human rights issues on human rights holders, an in-depth survey of salient human rights issues was conducted at 131 companies, including Group companies, suppliers, and contractors.

On-site Survey

In response to concerns extracted from the questionnaire survey, we conducted on-site inspections of three contractors together with third-party bodies related to sustainability to evaluate the actual situation.

[Survey methods]

The Kyocera Group identified human rights issues through the following three procedures:

- Confirmation with records and documents

The Kyocera Group checks records and documents managed by suppliers with the participation of responsible personnel at the suppliers. - Interviews of workers

The Kyocera Group conducted 20-minute interviews with workers, the directly impacted human rights holder, to understand the state of his/her work content, working hours, wages, living environment, safety and health, and discrimination and harassment. - Interviews with administrators

The Kyocera Group confirmed the details of the responses to the survey, and the state of management of overseas workers' interviews.

[Survey results and Approaches to corrective measures]

- The results of the on-site survey showed no serious human rights issues requiring immediate remedy.

- We did, however, discover management issues with the potential to lead to violations of laws and regulations (such as notification of paid leave) as well as environmental and safety issues evident in on-site work.

- In addition to explaining the need to correct the issues that were identified, we make proposals for improvement of the human rights issues discovered by our suppliers after on-site inspections to eliminate, prevent, or mitigate negative impacts on human rights; and we confirm that each company is proceeding with corrective measures.

- Further, the department in charge of the contractor works closely with individual contractors to improve issues on our premises.

Assessment of the Impact on Rights of Overseas Workers (Dialogue with Stakeholders) (FY2023 to FY2024)

Serious human rights violations have occurred in regard to overseas workers in Japan, including violations of the Minimum Wage Act and prohibition against forced return. In response, the Kyocera Group conducted a survey on salient human rights issues for overseas workers, who are vulnerable rights holders.

Ⅰ. Questionnaire Survey (FY2023)

A survey was conducted of 413 domestic suppliers of Kyocera.

[Survey results]

Domestic Suppliers

The survey response rate for domestic suppliers was 81% (335 companies). Among these domestic suppliers, 59% (197 domestic suppliers) had overseas workers.

| Subject domestic supplier | Domestic suppliers responding | Domestic suppliers with overseas workers | Domestic suppliers with overseas technical intern trainees |

|---|---|---|---|

| 413 | 335 (81%) | 197 (59%) | 65 (19%) |

According to the responses from 197 domestic suppliers, no salient human rights issues were identified. Meanwhile, potential human rights issues such as "consecutive work and overtime work" and "insufficient emergency drills and safety education" were identified. In addition, at the suppliers with overseas technical intern trainees, human rights issues specific to residence status such as "no confirmation of contract between dispatching and management organizations, and details regarding recruitment by a dispatching organization were identified.

Although no salient human rights issues were identified through this survey, the Kyocera Group identifies risks and discusses necessary measures when any potential human rights issue arises through continual hearings and interviews with suppliers.

Ⅱ. On-site Survey (FY2024)

To understand the state of overall concerns regarding domestic suppliers detected through the survey described in I above, the Kyocera Group conducted on-site surveys of suppliers with overseas workers, including technical intern trainees, (4 material suppliers, and 1 contractor) jointly with an external specialized agency.

[Survey methods]

The Kyocera Group identified human rights issues through the following three procedures:

- Confirmation with records and documents

The Kyocera Group checks records and documents managed by suppliers with the participation of responsible personnel at the suppliers. - Interviews of overseas workers

The Kyocera Group conducted 20-minute interviews with each overseas worker, the directly impacted human rights holder, to understand the state of his/her work content, working hours, wages, living environment, safety and health, and discrimination and harassment.

Interviews were conducted with 12 overseas workers at five subject suppliers (4 from the Philippines, 4 from Vietnam, and 4 from Myanmar). - Interviews with administrators

The Kyocera Group confirmed the details of the responses to the survey, and the state of management of overseas workers' interviews.

[Survey results]

- Through the hearing with overseas workers, the Kyocera Group confirmed that workers and administrators had appropriate communications, not only about training content, but also about concerns regarding daily living. The Kyocera Group also confirmed that suppliers with overseas technical intern trainees had a system for providing assistance to overseas workers in their languages with support from the management organization.

- On the other hand, some issues detected. These included suppliers being unable to provide multiple language assistance, suppliers not providing emergency drills at dormitories for workers, and suppliers not having any means in individual rooms to store personal valuables.

- The Kyocera Group also checked the following seven items, and found no relevant human rights issues.

①Child labor

②Payment of wages on a regular basis, payment of the full amount, and payment on time

③Personal ID card held by each worker / Freedom of movement of each worker

④Freedom of association and collective bargaining of each worker

⑤Health and safety of each worker

⑥Freedom from discrimination and unfair working conditions for female workers

⑦Freedom from excessively long working hours

[Approaches to corrective measures and future visions]

The Kyocera Group explained the need to correct identified human rights issues, and made proposals to improve human rights issues detected at suppliers after the on-site survey as actions to eliminate, prevent, and reduce negative impacts on human rights.

Some suppliers reported implementing corrective measures such as the installation of a safe for valuables in each dormitory room, and ensuring that all workers know about disaster evacuation centers on maps due to the difficulty of conducting emergency training since the dormitory is a rental apartment.

Suppliers also commented that they were unaware of the matters pointed out through this on-site survey. In addition, they indicated that workers did not know what to do when their dormitories were affected by disasters, and that there was a risk that workers may evacuate to factories handling dangerous substances. The Kyocera Group concluded that the survey led to positive and corrective approaches.

On the other hand, while the above-mentioned points were already publicized through the Kyocera Group Supply Chain Code of Conduct, it was found that they were not yet deeply understood by individuals working at supplier production sites.

In response to the survey results, the Kyocera Group continues monitoring supplier compliance with the Kyocera Group Supply Chain Code of Conduct through on-site surveys of and interviews with workers at suppliers. The Group strives for effective communication with partner companies that need to deepen their understanding thereof.

Installation of a Compliance Hotline

The Kyocera Group has established a compliance hotline with the aim of enhancing corporate governance, and detecting and preventing legal and compliance issues at an early stage. Anyone becoming aware of any action by an executive officer or employee of a Kyocera Group company that violates laws and regulations, the Kyocera Group CSR Guidelines, the Kyocera Group Human Rights Policy, or the Kyocera Corporation Labor-related Code of Conduct, is encouraged to contact the compliance hotline and provide the information outlined below.