Occupational Safety

Kyocera Group Environmental Safety Policy

The Kyocera Group is committed to creating a safe and secure work environment for our employees through the Kyocera Group Environmental Safety Policy, based on our Management Rationale.

The frequency of occupational accidents has been on the rise since FY2021. To reverse this trend, we will strive to increase employee awareness of risk by strengthening safety education. In the medium- to long-term, we will focus on continuing to create a safe workplace where all employees can work with peace of mind, aiming for an environment where mutual awareness is ever present to ensure a culture of safety fostered through safety management activities with the full participation of employees based on experience and diverse perspectives.

Kyocera Group Environmental Safety Policy

Based on Kyocera's founding company motto, "Respect the Divine and Love People," we established our management rationale "To provide opportunities for the material and intellectual growth of all our employees, and through our joint efforts, contribute to the advancement of society and humankind." Therefore, in addition to complying with laws and regulations on environmental safety, requirements agreed to by our company, and our own internal standards, we will continue to work to solve issues critical to society through communication with various stakeholders, participation in and support for social contribution activities, and by leveraging our technology and intellectual know-how.

Ensuring the safety and health of employees

- To create a safe and secure workplace for all employees, we will create a corporate culture in which everyone involved in our business activities is fully engaged.

- Kyocera will conduct risk assessments and reduce occupational health and safety risks by eliminating sources of danger to prevent workplace accidents and disasters.

- Kyocera strives to build a work environment where employees feel healthy, enjoy job satisfaction, and can reach their maximum potential by promoting mental and physical health.

Contribution to a sustainable society

- Kyocera will research, develop, produce, and expand products that contribute to the improvement of the global environment and products that reduce environmental impact throughout their life cycles.

- Kyocera will promote greenhouse gas emission control in our entire value chain to contribute to realizing a carbon-free society.

- Kyocera will contribute to realizing a recycling-oriented society by using resources more efficiently.

- Kyocera will strive to prevent environmental pollution by properly managing chemical substances in all processes.

- Kyocera will advance biodiversity conservation by minimizing the negative impact of our business activities on the natural environment and by protecting and nurturing the natural environment.

Operation of an environmental and safety management system

- During our business activities, through the operation of our management system, the Kyocera Group will proactively promote comprehensive measures for environmental protection and work safety, based on the management rationale, and continuously improve environmental and safety performance.

April 1, 2023

Kyocera Corporation

Hideo Tanimoto, President

Target

With the goal of reducing occupational accidents and eliminating the occurrence of fires, the Kyocera Group has established Kyocera Group Environmental Safety Targets.

Work-Related Accident Rate Within Kyocera Group (Japan)

| Targets for FY2025 | Work-related accident rate (including lost-time and non-lost-time accidents) is 0.66. The target for the number of fires incidents is 0. |

|---|---|

| Achievements in FY2025 | Achievements in FY2025 Work-related accident rate (including Lost-time and non-lost-time accident) was 1.04. The number of 7 fire incidents. |

| Targets for FY2026 | Work-related accident rate (including Lost-time and non-lost-time accident) is 0.66. The target for the number of fires incidents is 0. |

|---|

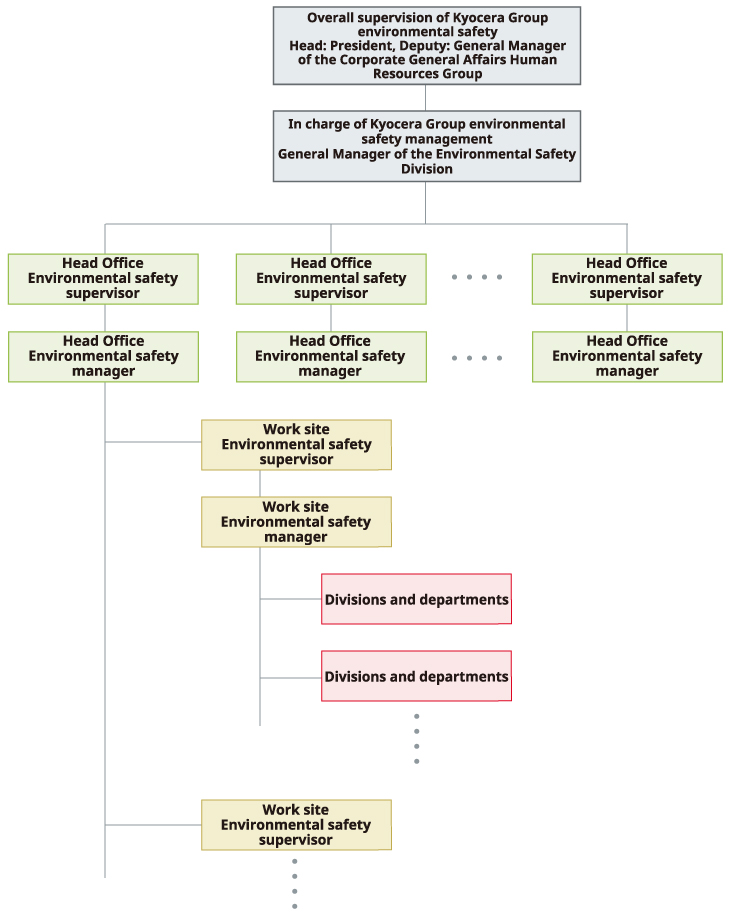

Occupational Safety Promotion System

The Kyocera Group has established a safety management system based on ISO45001 Occupational Health and Safety Management guidelines to promote occupational safety and health.

Environmental and Safety Management System

【Integrated Certification】

【Individual Certification】

Review of FY2025

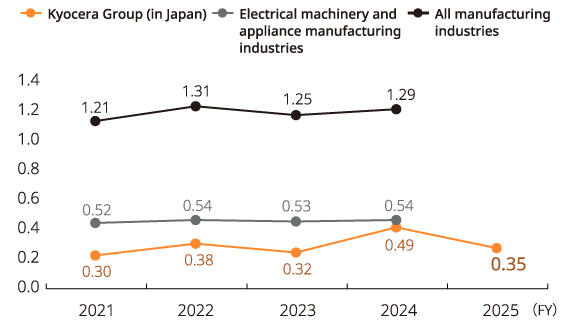

Changes Accident Rates (Japan)

The lost-time accident rate of the Kyocera Group (in Japan) in FY2025 was 0.35, the work-related accidents frequency rate (including Lost-time and non-lost-time accidents) was 1.04 (target: 0.66). There were 7 fires incidents (target: 0). We investigate the causes of accidents occurring at our worldwide locations and implement safety measures to remove any potential hazards.

Going forward, we will continue to reduce the number of industrial injuries and create a safe and secure working environment for all our employees.

Lost time accident rate

The lost time accident rates of all manufacturing industries and electrical machinery and appliance manufacturing industries are based on data from the Ministry of Health, Labour and Welfare.

Lost time accident rate: Number of afflicted persons / 1 million hours (The number of days of missed work is as per the standards of the Ministry of Health, Labour and Welfare.)

The Ministry of Health, Labour and Welfare figures utilize fiscal year data. (Lost time of one day or more)

Kyocera Corporation and Kyocera Group (in Japan) lost time accident rates utilize fiscal year data. (Lost time of one day or more)

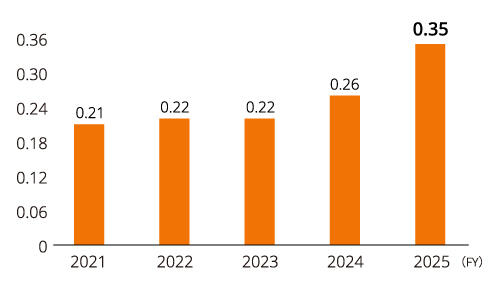

Occupational Disease Rate Within Kyocera Group (Japan)

| FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | |

|---|---|---|---|---|---|

| Occupational disease rate | 0.21 | 0.22 | 0.22 | 0.26 | 0.35 |

The occupational disease has been calculated based on all instances covered by the Appended Table 1-2 of the Ordinance for Enforcement of the Labor Standards Act (including diseases due to physical factors, diseases caused by the nature of the work, injuries caused by chemical substances, and others.)

Examples of Major Initiatives

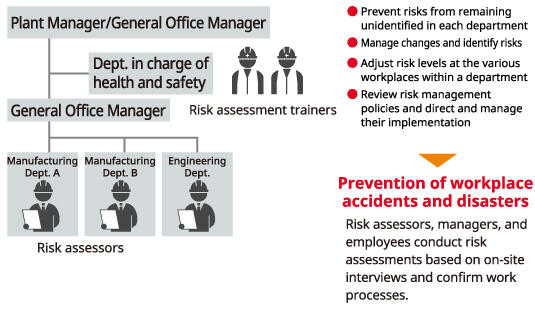

Risk Assessment and Special Patrols

In order to prevent accidents, in Japan, we appoint risk assessment trainers and risk assessors at each business site and continue to develop risk assessment measures. Risk assessment trainers and risk assessors receive practical training and lectures regarding the necessary base knowledge and skills. They then perform risk assessments to gain an understanding of hazards through the appropriate identification and evaluation of risks before implementing countermeasures. This serves to prevent accidents before they occur.

In addition, as accident and disaster risks may vary constantly with the introduction and modification of machinery and other equipment, re-investigation of accident risks and risk assessments are conducted routinely.

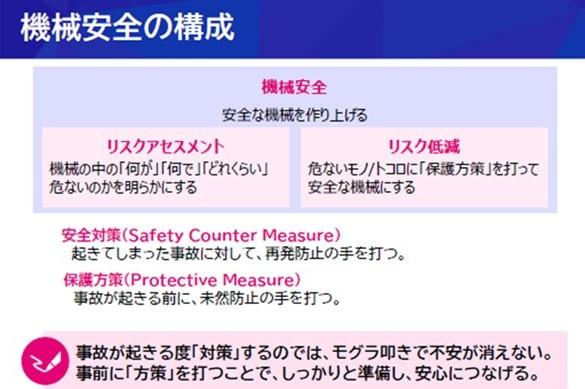

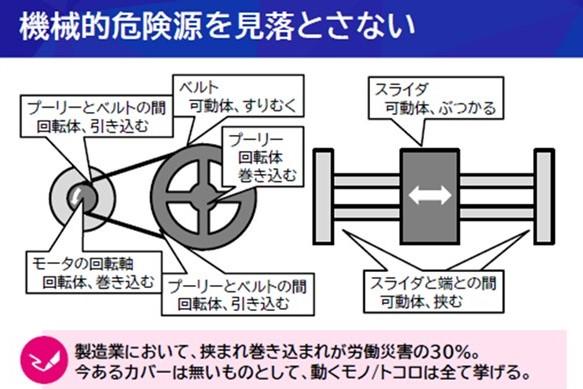

Risk Assessment Overview

Risk Assessment Competency Improvement

In Japan, risk assessments are conducted by risk assessors. Since FY2022, we have strived to improve the competence of risk assessors by providing training on machinery safety and effective risk assessment with an external specialist organization to identify risks more effectively. This will help us improve the competence of risk assessment trainers and assessors and help conduct more effective risk assessments to prevent accidents in the future.

Training Text: Adapted from Japan Certification Corporation's Hazard Identification and Risk Assessment Competency Improvement Education

and Training Textbook

Hazard Awareness Training Using Virtual Reality (VR)

Kyocera Corporation runs hazard awareness training that utilizes VR. Inexperienced employees are given a virtual experience of the dangers inherent in their work. This boosts their hazard awareness and makes them more safety-conscious in their actions.

VR hazard awareness training content

Implementation of Emergency Measures and Training

Kyocera conducts fire drills annually to prepare for fires and other emergencies.

Response to Exposure to Chemical Substances and Noise

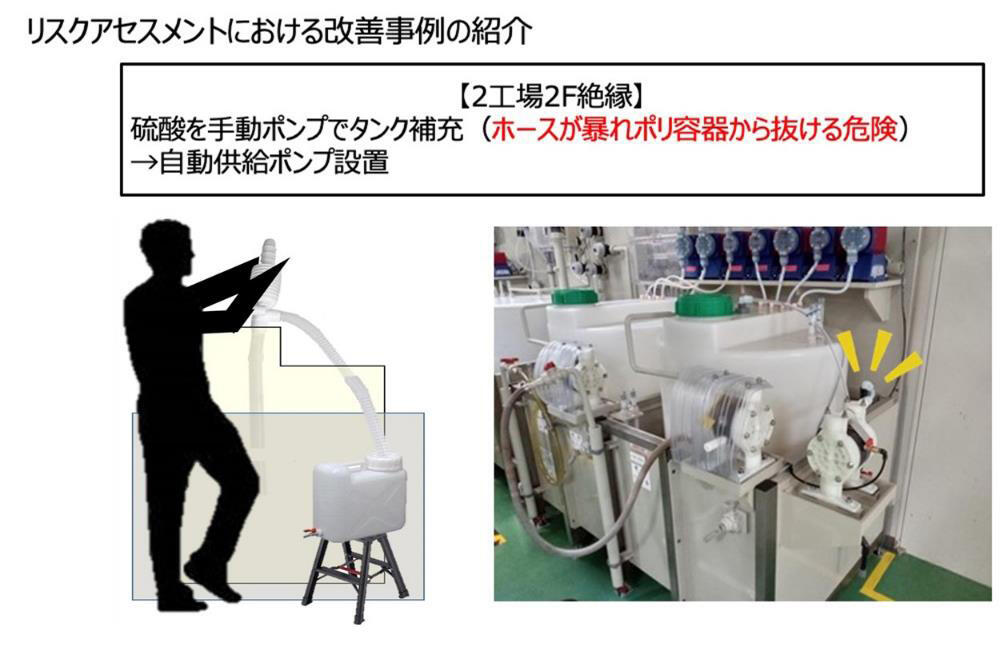

As an effort to reduce employee risk of exposure to chemical substances in the manufacturing process, we have shifted from a manual transfer method to an automatic supply system using an air-driven pump. In addition, we have made it mandatory for all employees to wear protective equipment; and to prevent exposure to noise, all employees are required to wear earplugs and other protective equipment.

Regular Environmental and Safety Patrols

At Kyocera, plant/office managers and safety managers periodically conduct safety patrols at worksites. In addition to these patrols, the overall supervision of Kyocera Group environmental safety conducts an environmental and safety inspection on a regular basis. These activities aim to share risks and issues at worksites and raise employees' safety awareness.

Holding Information Sessions on Workplace Safety

The Kyocera Group regularly holds information sessions about onsite work safety to prevent business partners who enter our sites for service or other related work from being involved in accidents. We hold information sessions to explain campus safety work rules, chemical substance handling, and activities for accident prevention. During these sessions, Kyocera staff and business partners confirmed safety precautions and shared a renewed sense of safety awareness. We will continue to hold briefing sessions to prevent accidents involving our suppliers on our premises.

Promotion of Safety and Health Measures Based on Labor-Management Cooperation

The Kyocera Group holds Safety and Health Committee meetings at least once a month for the purpose of smooth and reliable implementation of safety and health management activities at workplaces. During the meetings, the company and labor union cooperate on employee safety and health issues, discussing matters such as the prevention of hazards and health problems, occupational accident reporting and countermeasures, health checkups, safety and health education plans, and other issues.

Deployment of Kyocera Perfect 5S Promotion Activities

The 5S (Seiri: Sort / Seiton: Set in Order / Seiso: Shine / Seiketsu: Sanitize / Shitsuke: Sustain) is at the heart of work at the Kyocera Group. Aiming to implement 5S activities perfectly at every worksite, Kyocera Perfect 5S Promotion Activities are being introduced globally. Each worksite regularly evaluates the degree of 5S achievement using a company-wide standardized checklist and identifies areas for improvement. Then all members work together to make improvements in the areas identified. 5S training provides an understanding of the objectives and effects of 5S promotion activities. Employees who have completed this training serve as evaluators in order to ensure fair and impartial evaluation and objective judgment. Through these activities, Kyocera aims to create a working environment where every employee can work safely and with peace of mind and to raise each employee's awareness of and commitment to 5S.