Solution Technologies

Kyocera has contributed to the technological innovation of its customers by providing many creative ceramic components to the world. Here are Kyocera's various ceramic applications.

-

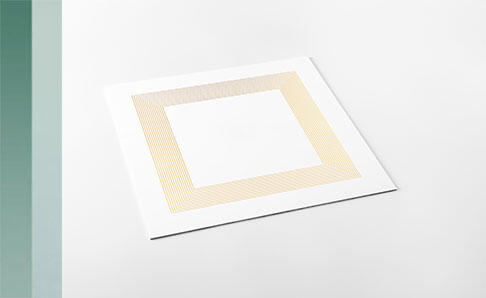

- High-precision machining

Metallized Large Ceramic SubstrateLearn More -

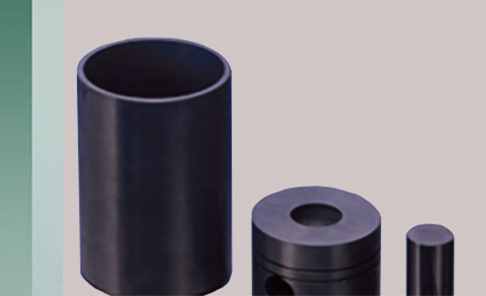

- Material

High-Temperature High-Strength Silicon Nitride (SN282A)Learn More -

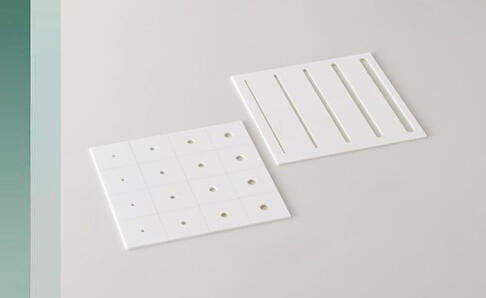

- High-precision machining

High-Precision Laser Processing TechnologyLearn More -

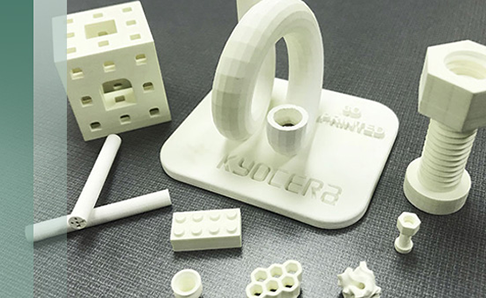

- Complex geometry

Ceramic Additive ManufacturingLearn More -

- Material

- Design

- Evaluation

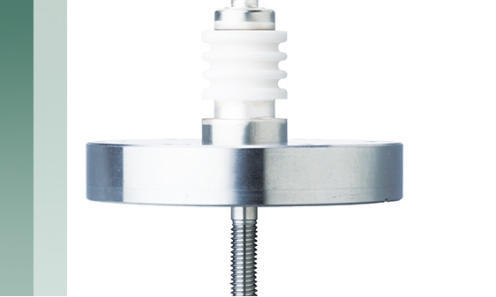

High Voltage Solutions (Ceramic Materials/Design/Evaluation)Learn More -

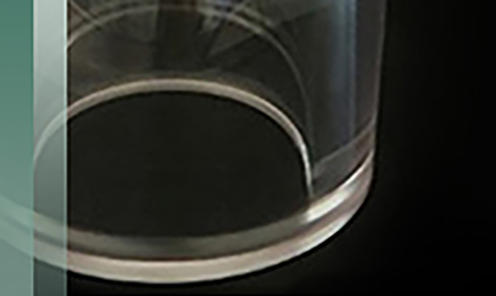

- Material

Optical Components - Sapphire WindowsLearn More -

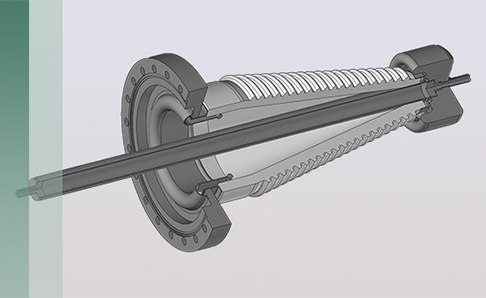

- Complex geometry

Integral Molding with Complex Internal Shape: F-MoldingLearn More -

- Joint

Alumina Multi-layer Diffusion BondingLearn More -

- Surface modification

Semiconductive Ceramic CoatingLearn More -

- Material

Low Dielectric Loss Tangent, High Strength, and High Purity Alumina (AO479U)Learn More -

- High-precision machining

Large Sapphire Manufacturing TechnologyLearn More -

- Material

ESD Protection Zirconia CeramicsLearn More -

- Material

High Thermal Conductivity Silicon Nitride Ceramics (SN241O)Learn More -

- High-precision machining

Lapping and Polishing Technology for Complex Shaped Sapphire ProductsLearn More -

- High-precision machining

High Precision Ceramic Nozzle with Micro HoleLearn More -

- High-precision machining

- Complex geometry

Small, Thin Ceramic Injection Molding: CIMLearn More -

- Material

Zirconia Toughened Alumina (ZTA)Learn More -

- High-precision machining

Laser Micro Machining on SapphireLearn More -

- Material

High Voltage-Resistant Alumina Ceramics (AH100A)Learn More -

- Joint

- Complex geometry

Simultaneous Sintering and Bonding Technology: Green BondingLearn More -

- Joint

Alumina and Sapphire Direct Bonding TechnologyLearn More -

- Complex geometry

Complex Shape Forming Technology: F-MoldingLearn More