"F-Molding" is a new molding method developed by Kyocera that achieves a large near-net shape by pouring a slurry of raw materials into a mold. Products made using this method have comparable characteristics to products made by the CIP method.

Read more about our F-Molding below.

F-Molding

This "F-Molding" technology enables the integrated molding of products with complex internal geometries, which is difficult to achieve with conventional methods of grinding from bulk.

Example of Shapes

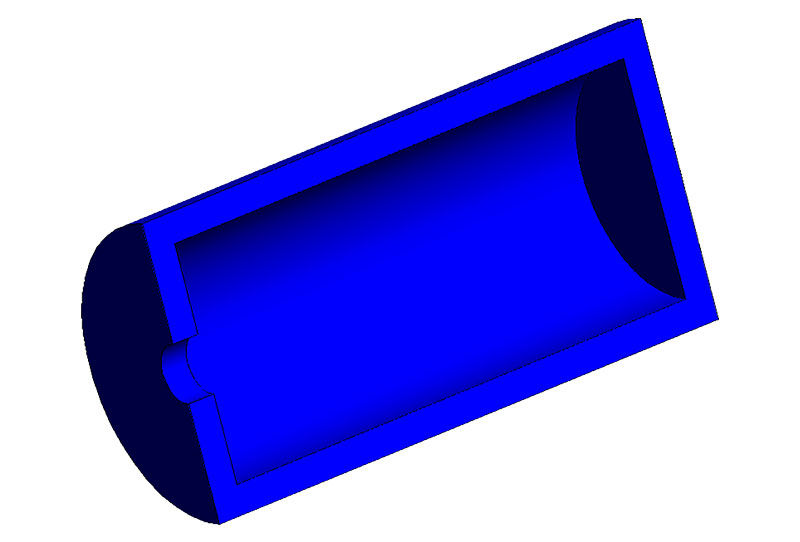

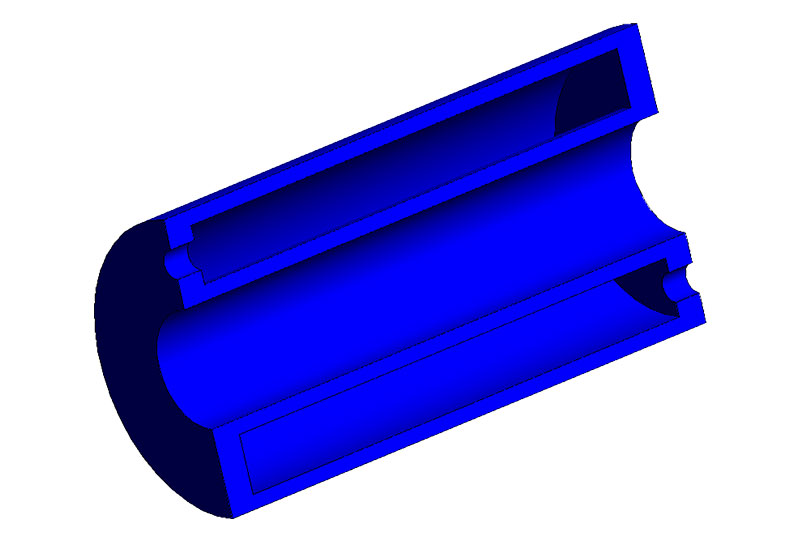

Nozzle shape with internal stops and complex geometry

| External view | Cross-sectional view |

|---|---|

|

|

|

|

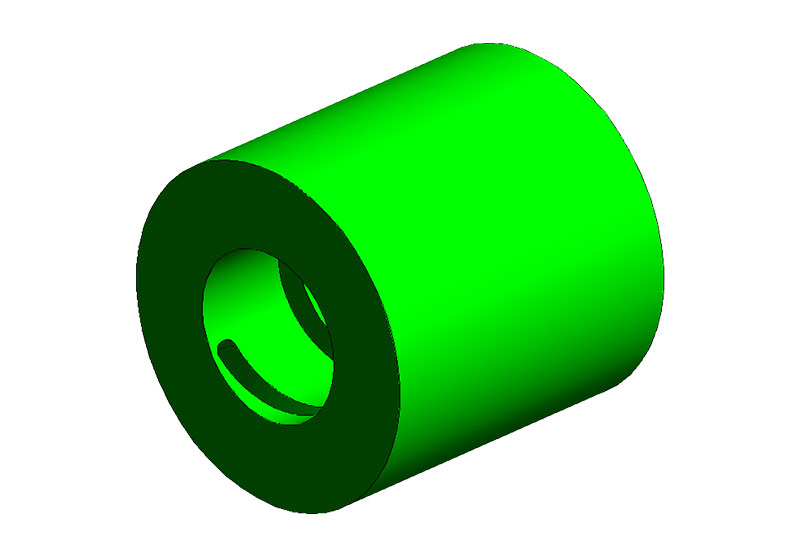

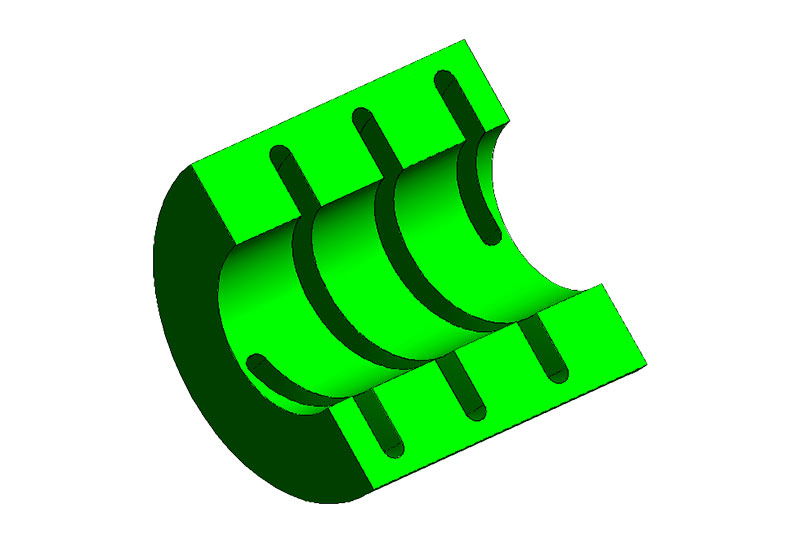

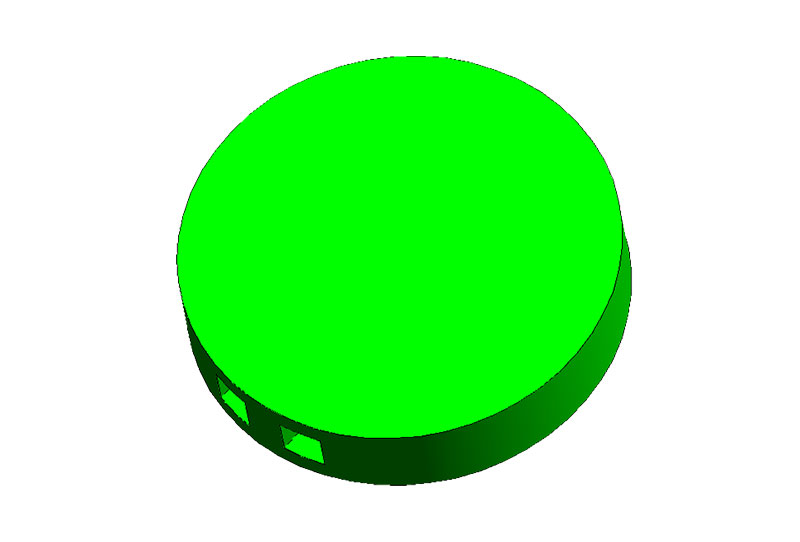

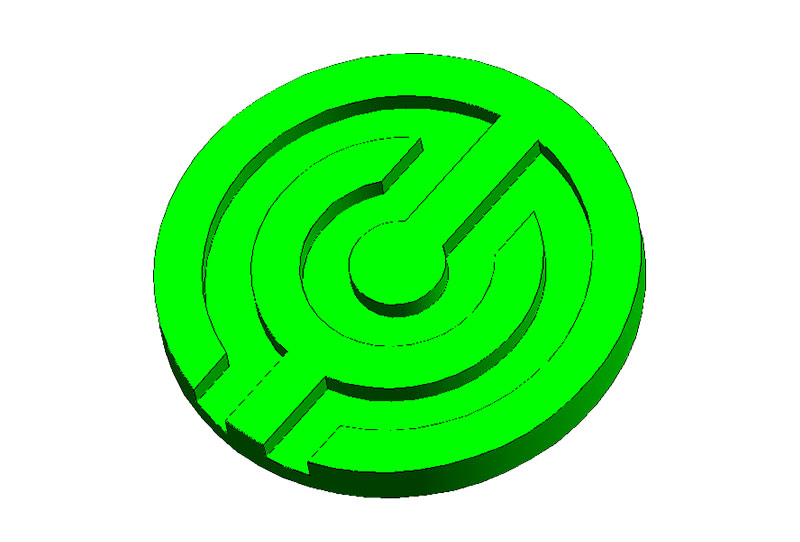

One piece without joint marks, with internal flow channel structure

| External view | Cross-sectional view |

|---|---|

|

|

|

|

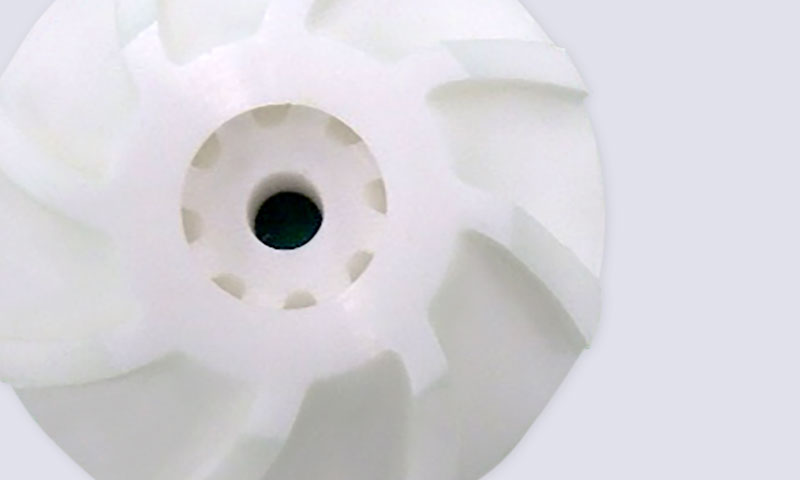

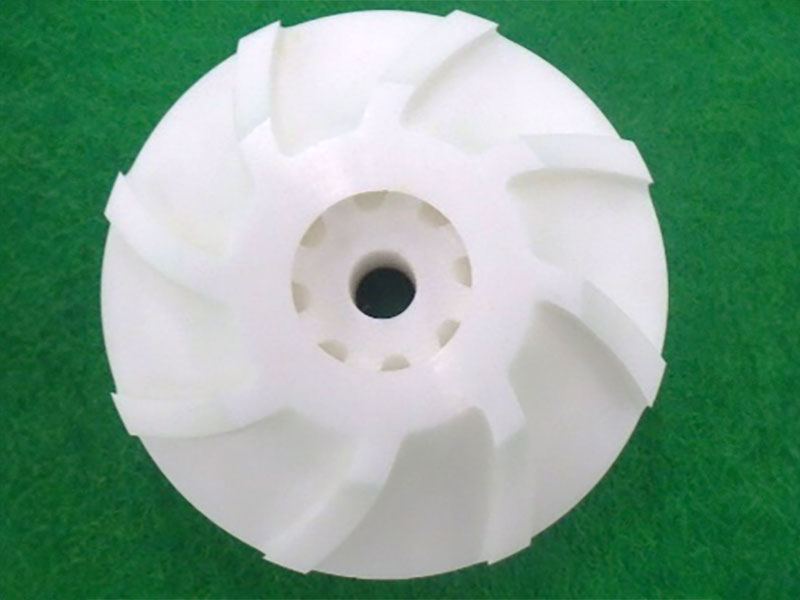

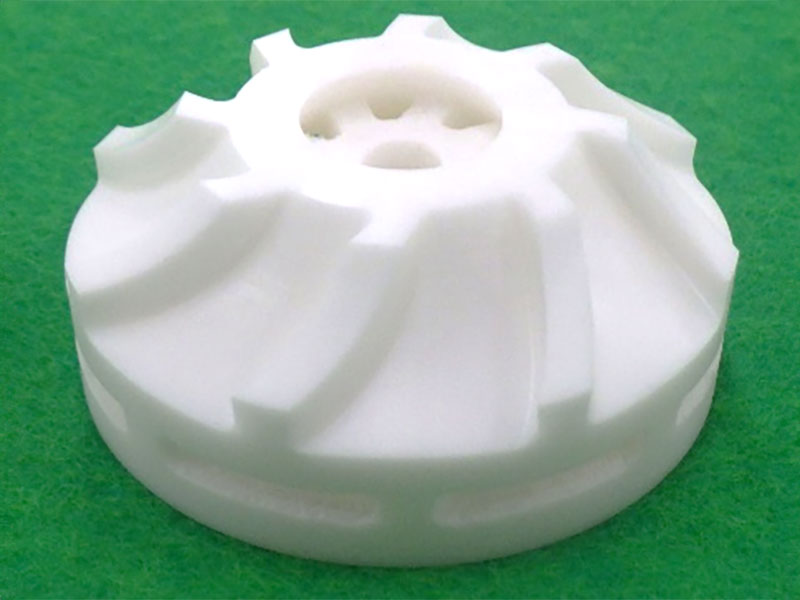

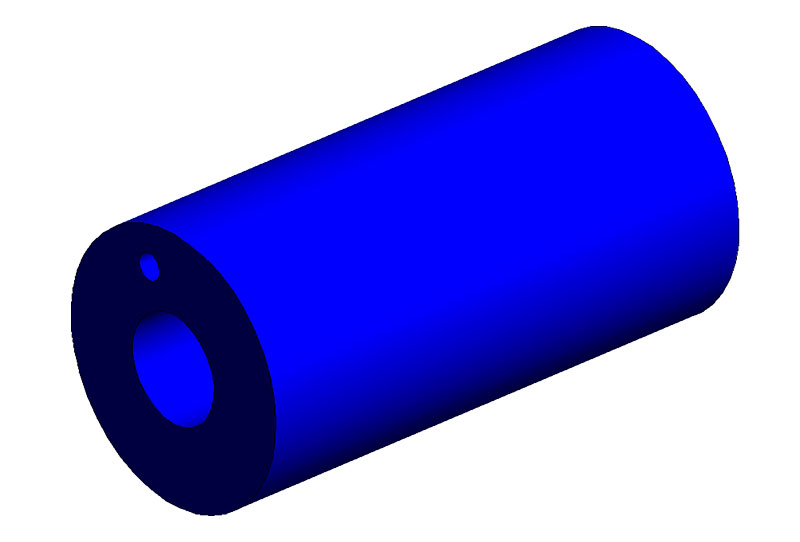

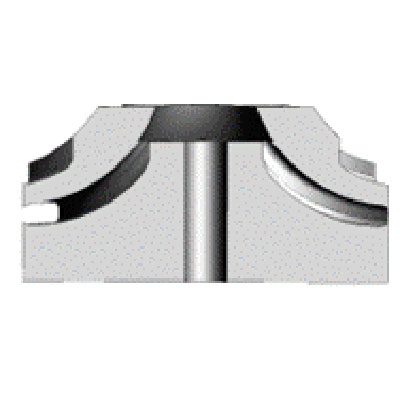

Sample Image

*Material: Zirconia (ZO206N) Size: Φ50mm

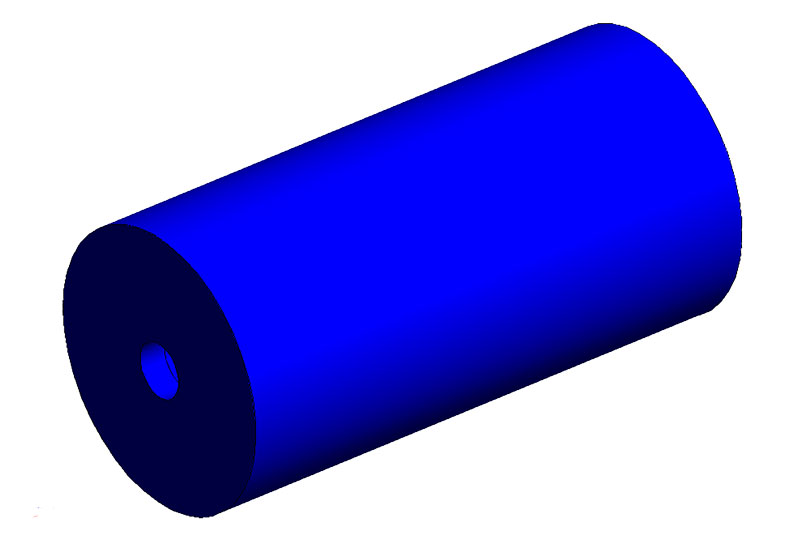

3D Model

| External view | Cross-sectional view |

|---|---|

|

|

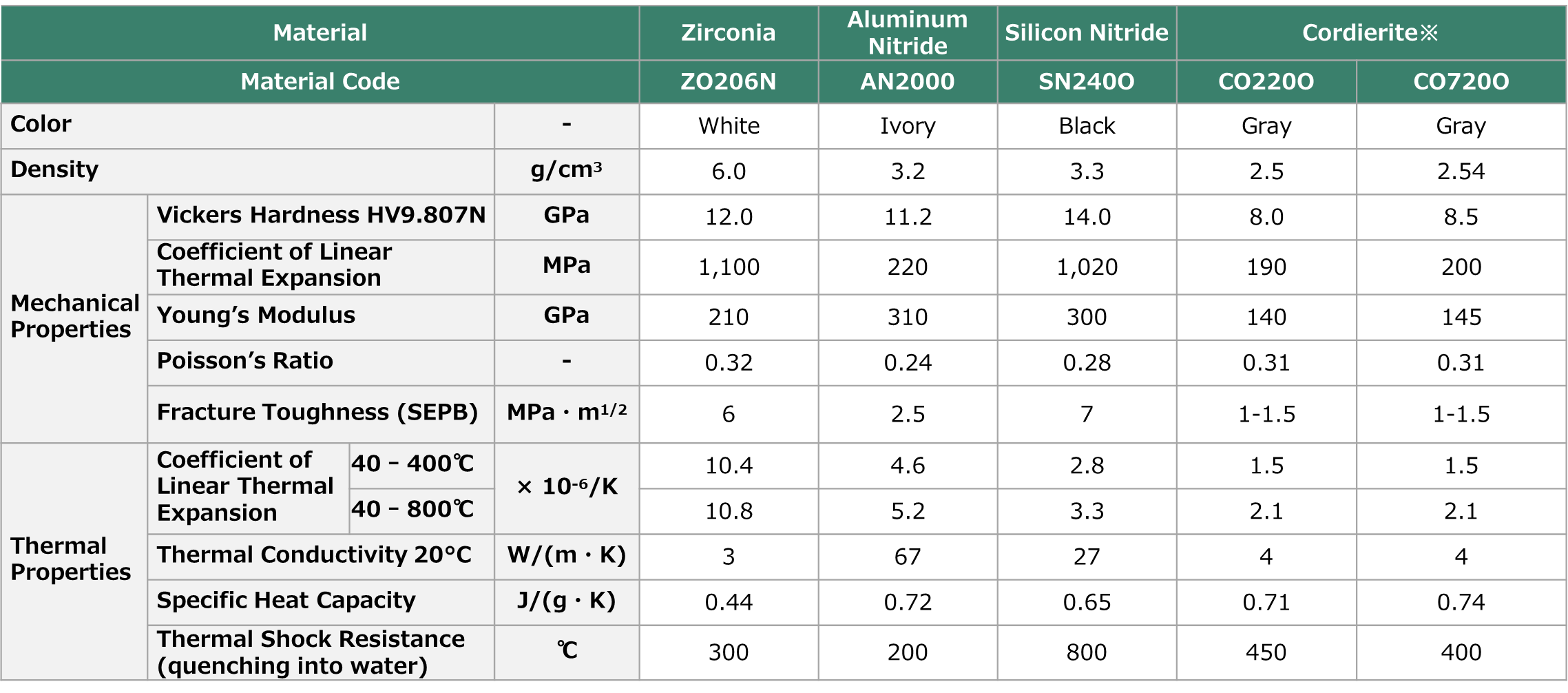

Material Lineup

*The application of cordierite materials to the integrated molding of complex internal shapes is still in the development stage.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.