Ceramic Materials

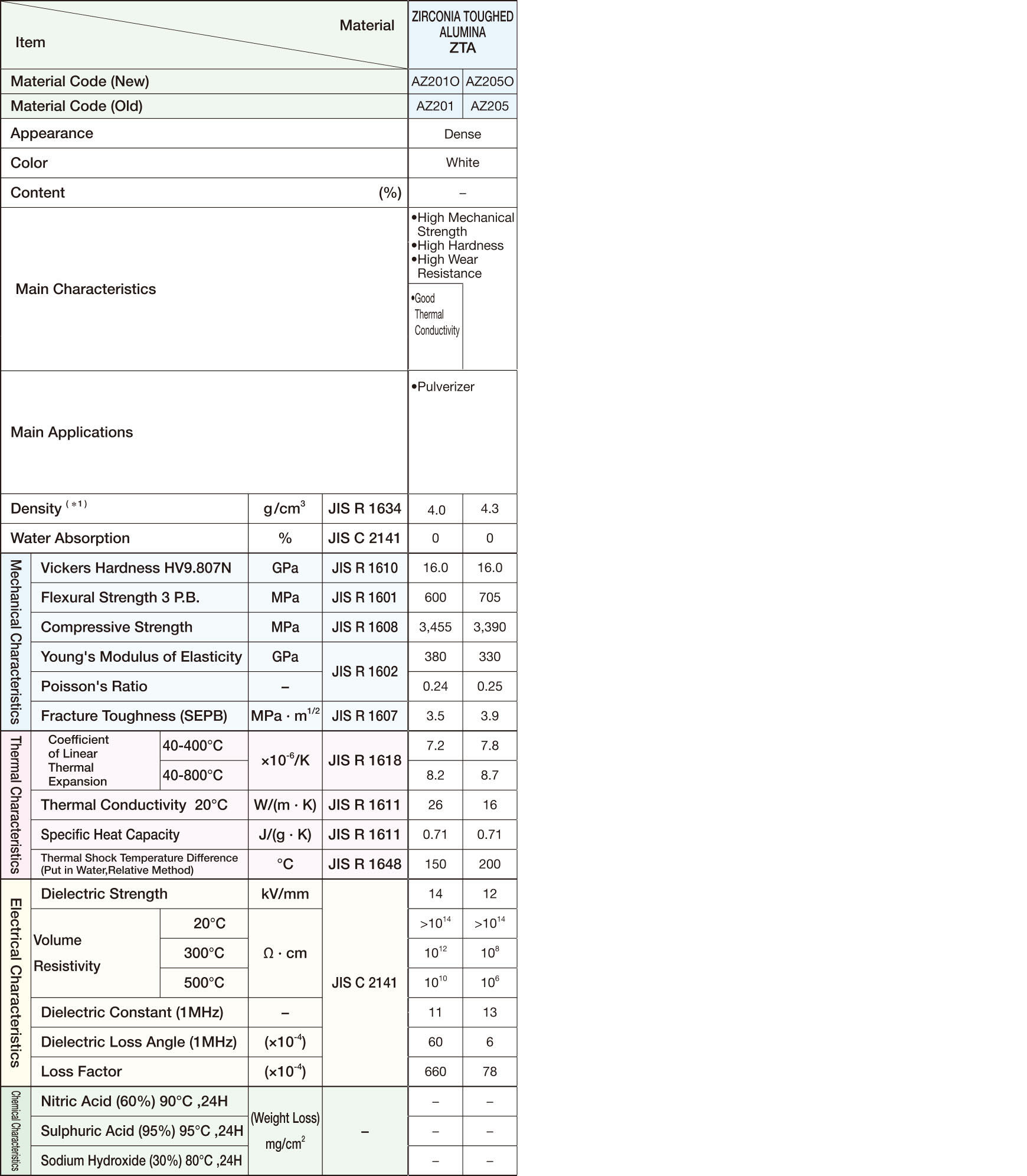

Zirconia Toughened Alumina (ZTA)

Composite material of alumina and zirconia has excellent wear resistance

Zirconia Toughened Alumina is a composite material made of alumina and zirconia. It has a hardness and bending strength higher than that of alumina, with a lower thermal expansion than zirconia, and is characterized by high thermal conductivity. Taking advantage of its high wear resistance, it is widely used for wear-resistant parts that require cooling, including crusher parts.

- Important property :

- Hardness

- Flexural Strength

- Coefficient of Thermal Expansion

- Thermal Conductivity

Features

-

High stiffness and outstanding wear resistanceStiffer than alumina with outstanding wear resistance equivalent to zirconia.

-

High thermal conductivity and low thermal expansionSuppresses thermal deformation through thermal conductivity and low thermal expansion equivalent to alumina. Suitable for components requiring a cooling Mechanism.

-

High strength and specific rigidityApproximately twice as strong as alumina and contributes to low-weight design through high specific rigidity.

Property

Ceramic Materials

- AluminaAl2O3

- Single-Crystal SapphireAl2O3

- ZirconiaZrO2

- Silicon NitrideSi3N4

- Silicon CarbideSiC

- Zirconia Toughened AluminaZTA

- Cordierite2MgO・2Al2O3・5SiO2

- CermetTiC,TiN

- YttriaY2O3

- Single-Crystal YAGY3Al5O12

- YAG-dispersed AluminaAl2O3

- Aluminum NitrideAlN

- Silicon-Infiltrated Silicon CarbideSiSiC

- Porous Ceramics

Customizable

We have a wide range of technologies such as material technology, process technology, design technology, measurement/evaluation technology, and integrated processes from materials to products in-house, so we can respond to various customizations. Please feel free to contact us first.