Product Search by Industries

Electronics

Various ceramic substrates are widely used to improve the reliability of circuit patterns. The excellent characteristics of ceramics are utilized in sensor parts that require high sensing accuracy. For example, ceramics are used as membranes for pressure sensors, which require high dimensional accuracy, and sapphire windows for coin sensors, which require scratch resistance and optical transparency. Semi-conductive ceramics are used in electronic component manufacturing processes that require electrostatic discharge (ESD) protection.

Product examples

-

Pressure Sensor ComponentsKyocera's high-precision ceramic technology supports sensors for a wide range of pressure conditions.

- Heat Resistance

- Insulation Property

-

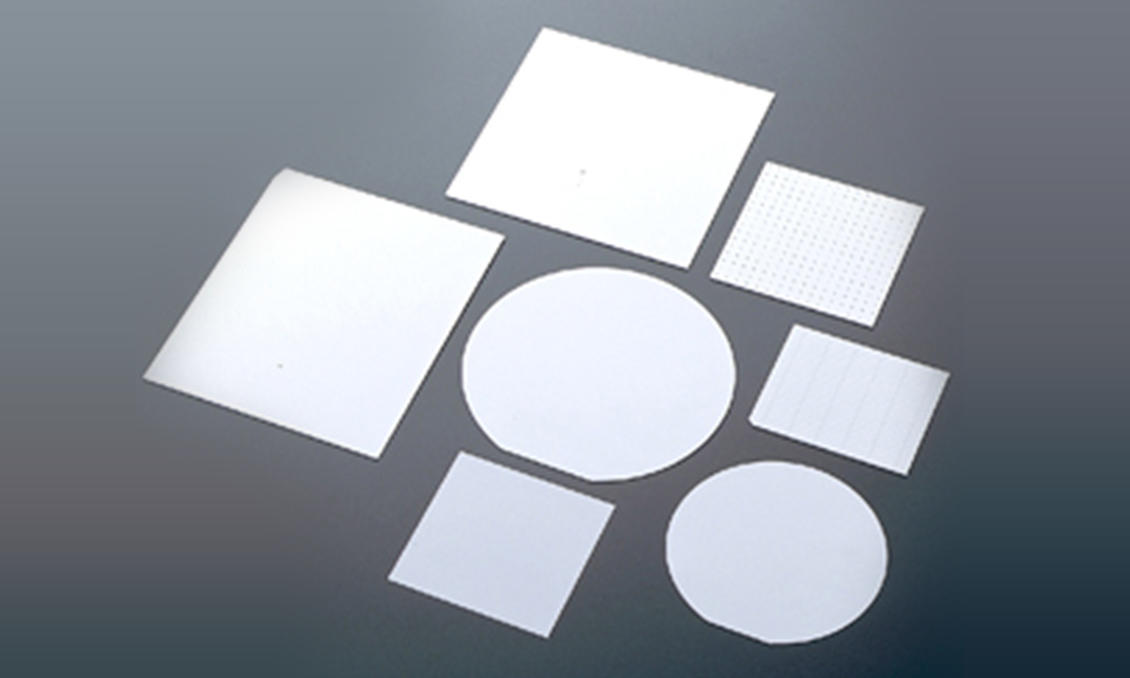

Substrates for Power ModulesHigh-strength substrates compatible with the direct bonding of copper sheets are suitable for a wide range of power module applications.

Substrates for Power ModulesHigh-strength substrates compatible with the direct bonding of copper sheets are suitable for a wide range of power module applications.- High Strength

- Low Thermal Expansion

-

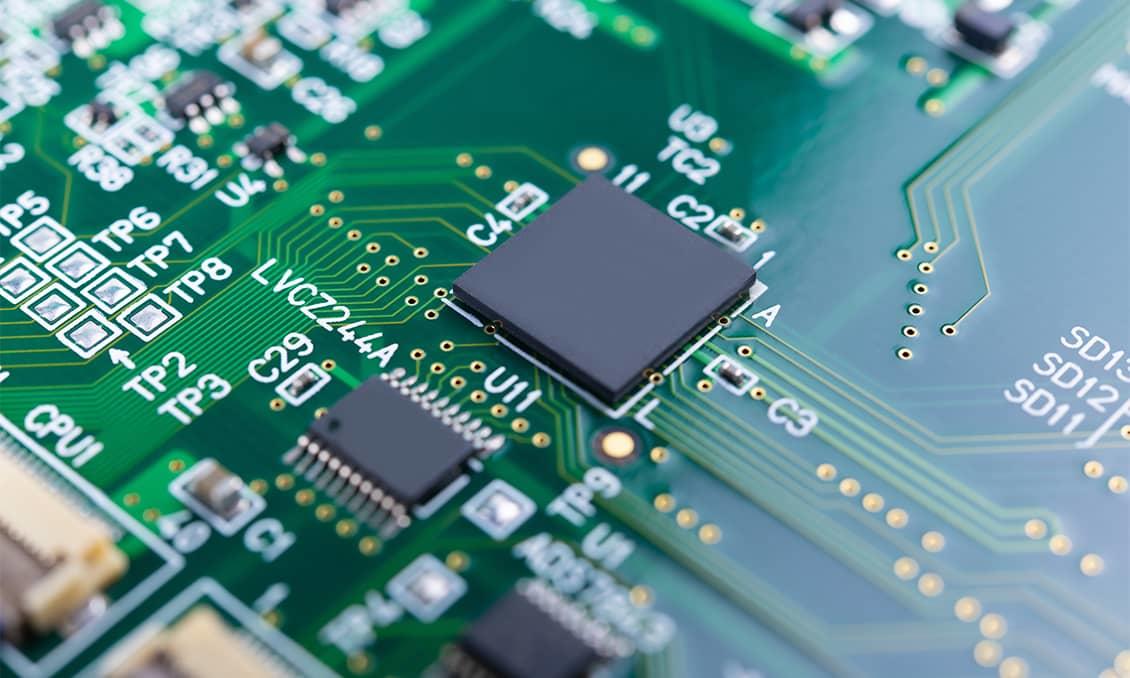

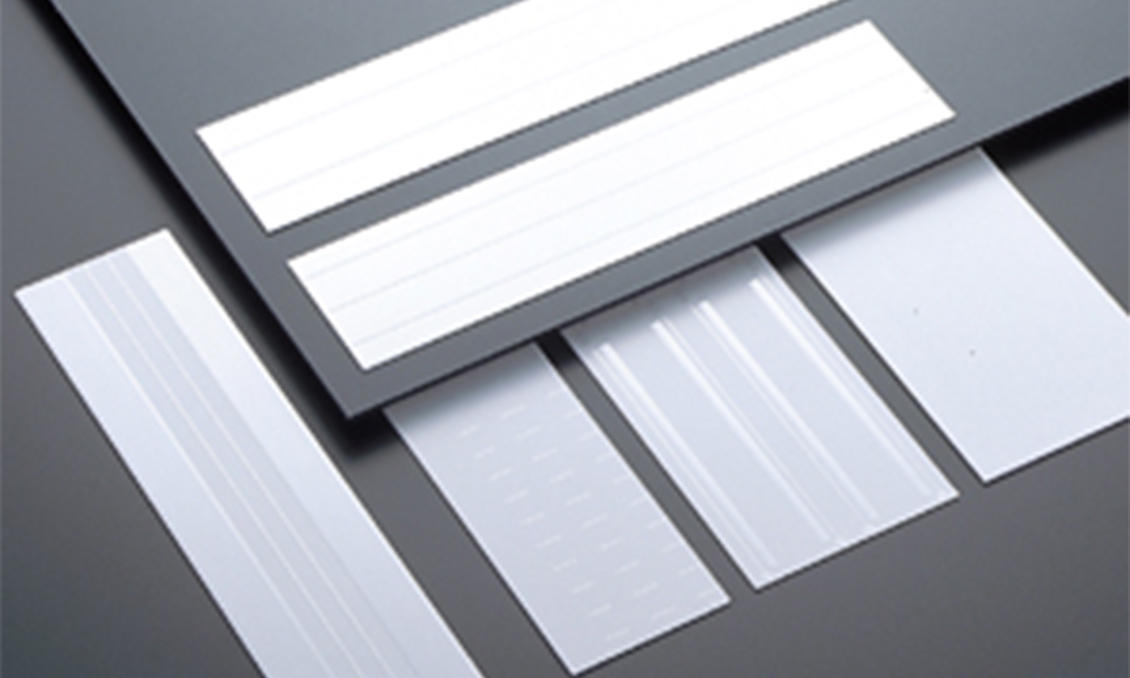

Thick Film SubstratesKyocera's thick film substrates correspond to the increased density and precision of thick film circuits.

Thick Film SubstratesKyocera's thick film substrates correspond to the increased density and precision of thick film circuits.- Large Sizes Available

- Thick Film Reliability

-

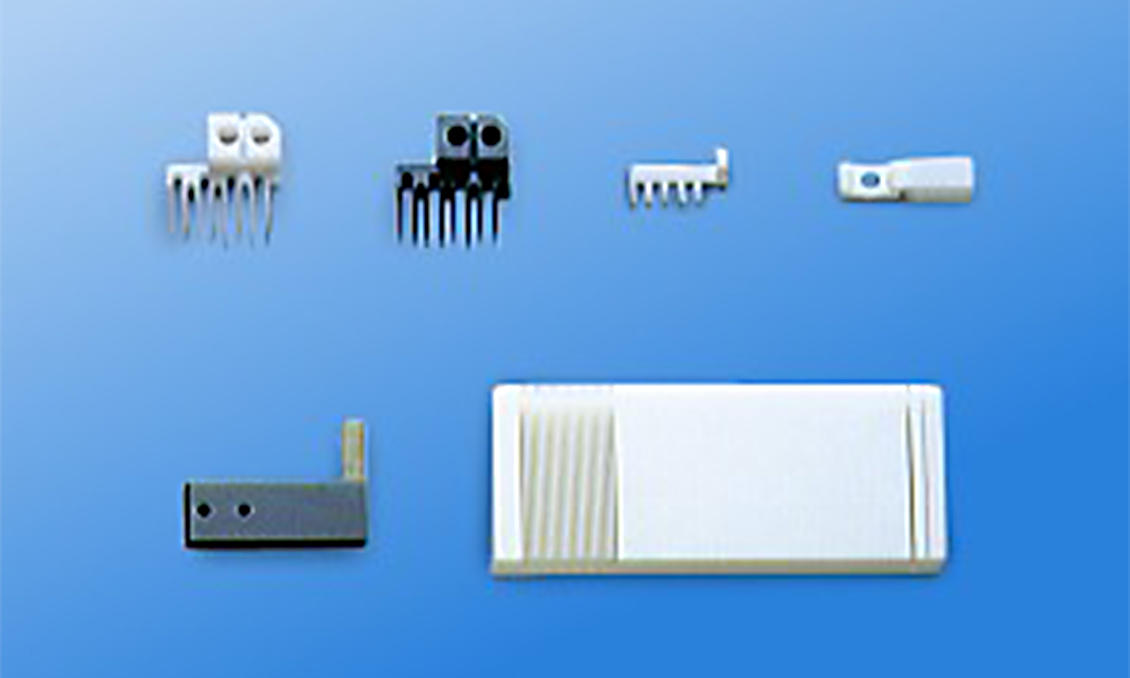

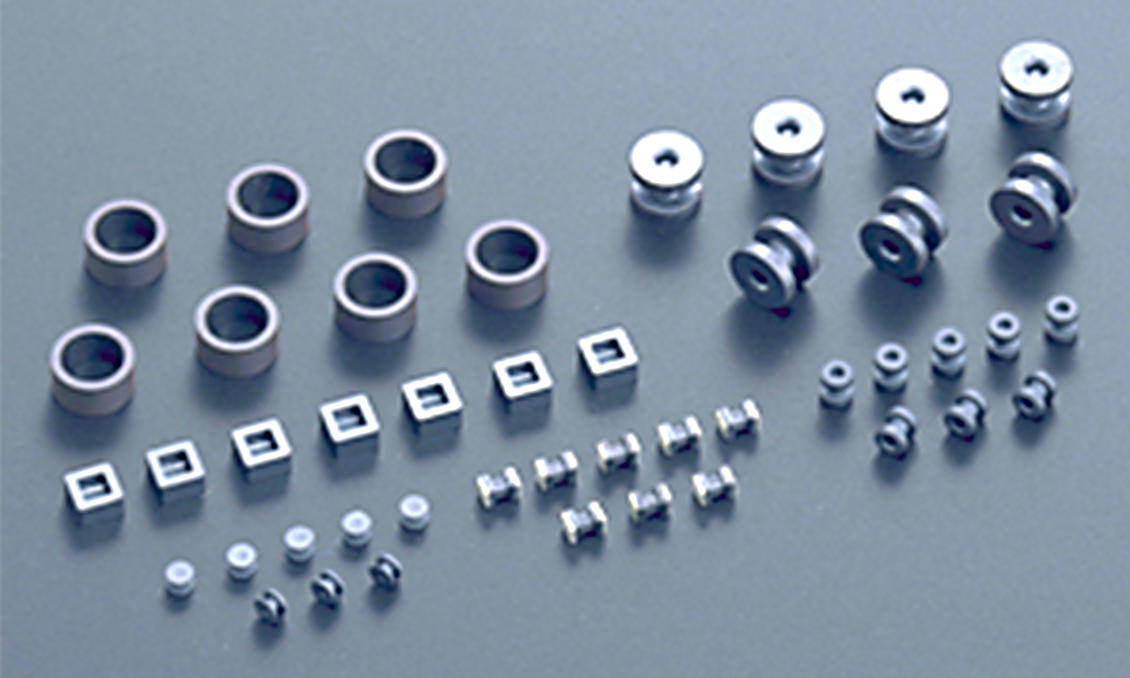

Pressed and Extruded PartsOptimum material selection and forming technology contribute to the improved performance of electronic devices.

Pressed and Extruded PartsOptimum material selection and forming technology contribute to the improved performance of electronic devices.- Wide Variety of Materials

- Various Shaping/Forming Technology

-

Thin Film SubstratesThin film substrates with superior surface smoothness.

Thin Film SubstratesThin film substrates with superior surface smoothness.- Excellent Surface Smoothness

-

Polished SubstratesPolished thin-film substrates with excellent surface smoothness, tight thickness tolerance and excellent flatness.

Polished SubstratesPolished thin-film substrates with excellent surface smoothness, tight thickness tolerance and excellent flatness.- Excellent Surface Smoothness

-

Glazed Substrates for Thermal PrintheadsGlazed substrates that are ideal for increasingly high-resolution printer heads.

Glazed Substrates for Thermal PrintheadsGlazed substrates that are ideal for increasingly high-resolution printer heads.- Fewer Surface Voids

- Surface Smoothness

-

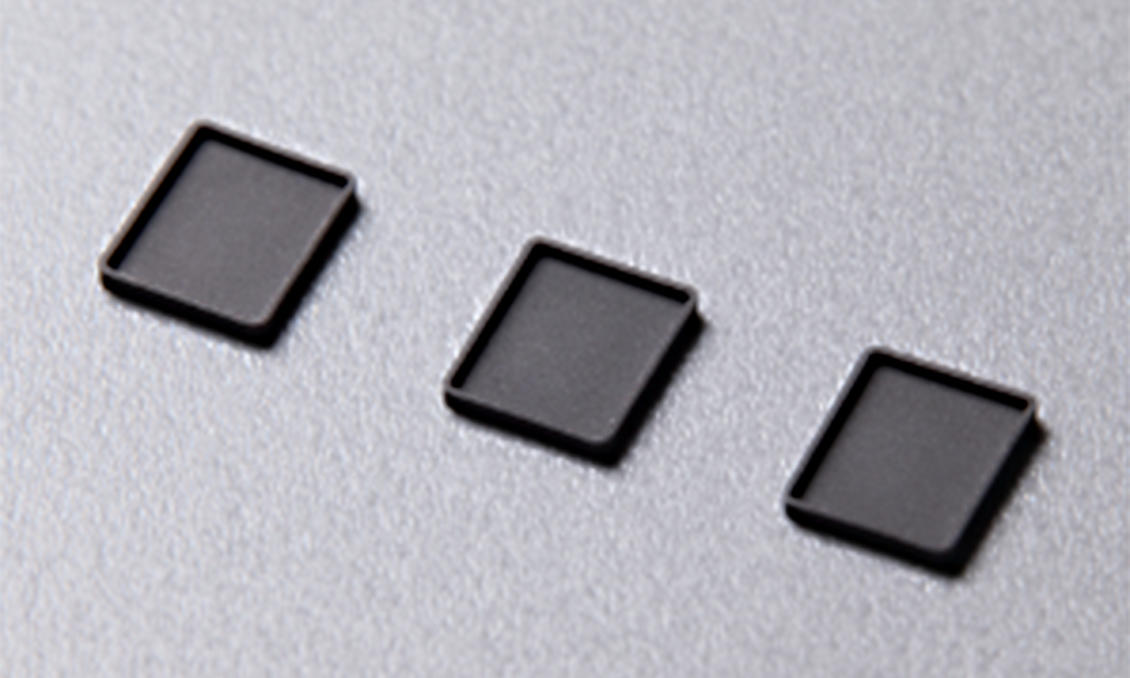

Ultra Thin Ceramic CapsUltra thin, enabling devices to be made smaller in size and lower in height.

Ultra Thin Ceramic CapsUltra thin, enabling devices to be made smaller in size and lower in height.- Various Shaping/Forming Technology

- Mass Production

-

ESD TweezersDeveloped for products and processes sensitive to electrostatic breakdown.

- Semiconductive

- Chemical Stability

-

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.- Design flexibility

- High-Temperature Durability

-

Hard Disk Drive (HDD) Head Processing Tools and FixturesCeramic tools and fixtures that offer high rigidity and ESD safety properties.

Hard Disk Drive (HDD) Head Processing Tools and FixturesCeramic tools and fixtures that offer high rigidity and ESD safety properties.- High Stiffness

- Chemical Stability

-

Substrates for Thin-Film Magnetic Heads in Hard Disk Drives (HDDs)Hard Disk Drive (HDD) head substrates are suitable for ultra-high-precision processing.

Substrates for Thin-Film Magnetic Heads in Hard Disk Drives (HDDs)Hard Disk Drive (HDD) head substrates are suitable for ultra-high-precision processing.- High Strength

- High Stiffness

-

Ferrite ProductsA variety of materials are available for diverse property and frequency requirements.

Ferrite ProductsA variety of materials are available for diverse property and frequency requirements.- Magnetic Material

-

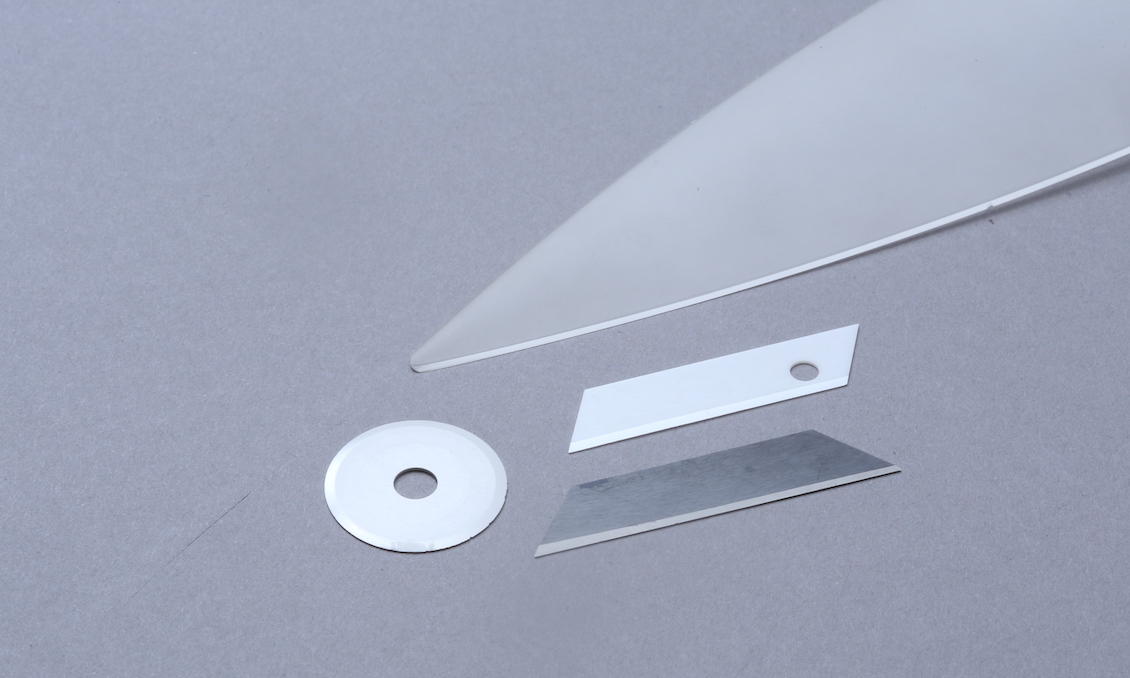

Cutters and Wear-Resistant Parts for Industrial MachineryKyocera's cutters are ideal for a variety of materials and high-precision machining technologies.

Cutters and Wear-Resistant Parts for Industrial MachineryKyocera's cutters are ideal for a variety of materials and high-precision machining technologies.- Wear Resistance

- Precision Machining

-

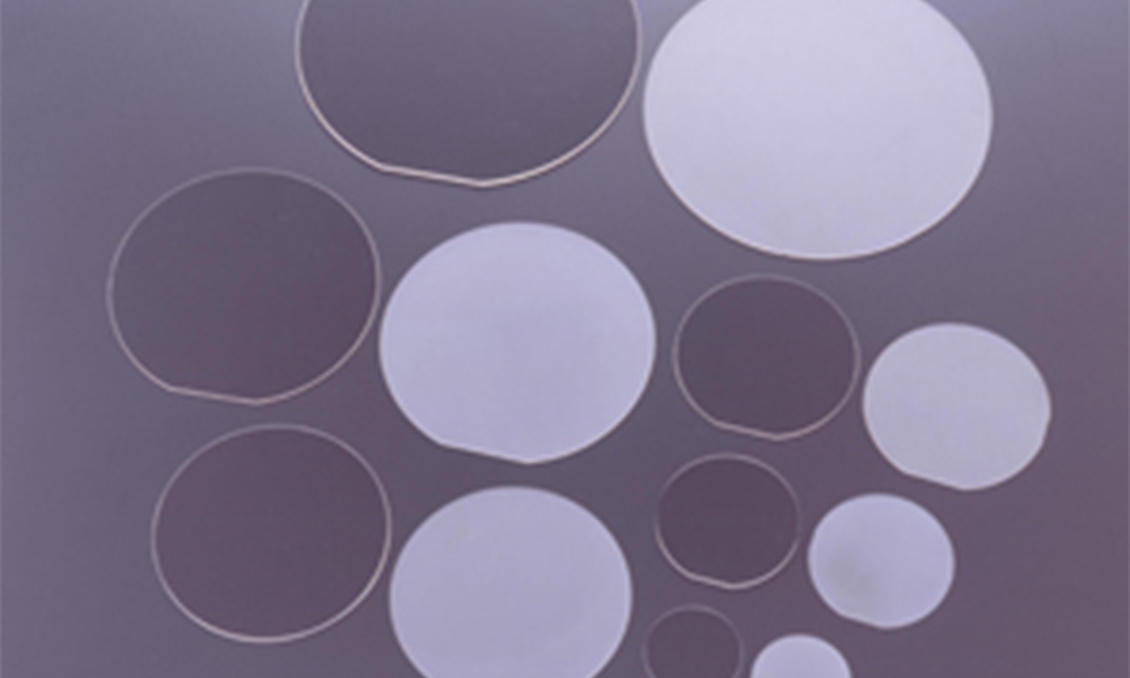

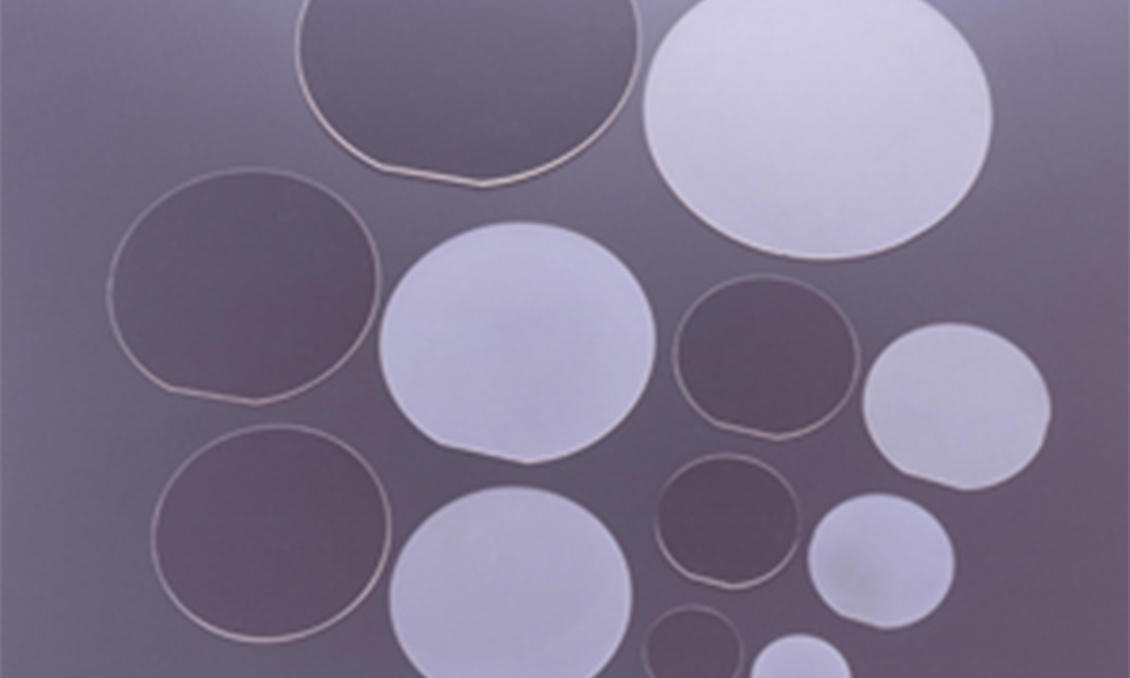

Sapphire Substrates for LEDsSapphire substrates are highly regarded in the LED industry for their reliability, abundance and cost efficiency.

Sapphire Substrates for LEDsSapphire substrates are highly regarded in the LED industry for their reliability, abundance and cost efficiency.- High Strength

- Thermal Stability

-

Sapphire Wafers for Electronic DevicesKyocera's sapphire wafers feature excellent material properties and mass-producibility.

Sapphire Wafers for Electronic DevicesKyocera's sapphire wafers feature excellent material properties and mass-producibility.- High Strength

- Thermal Stability

-

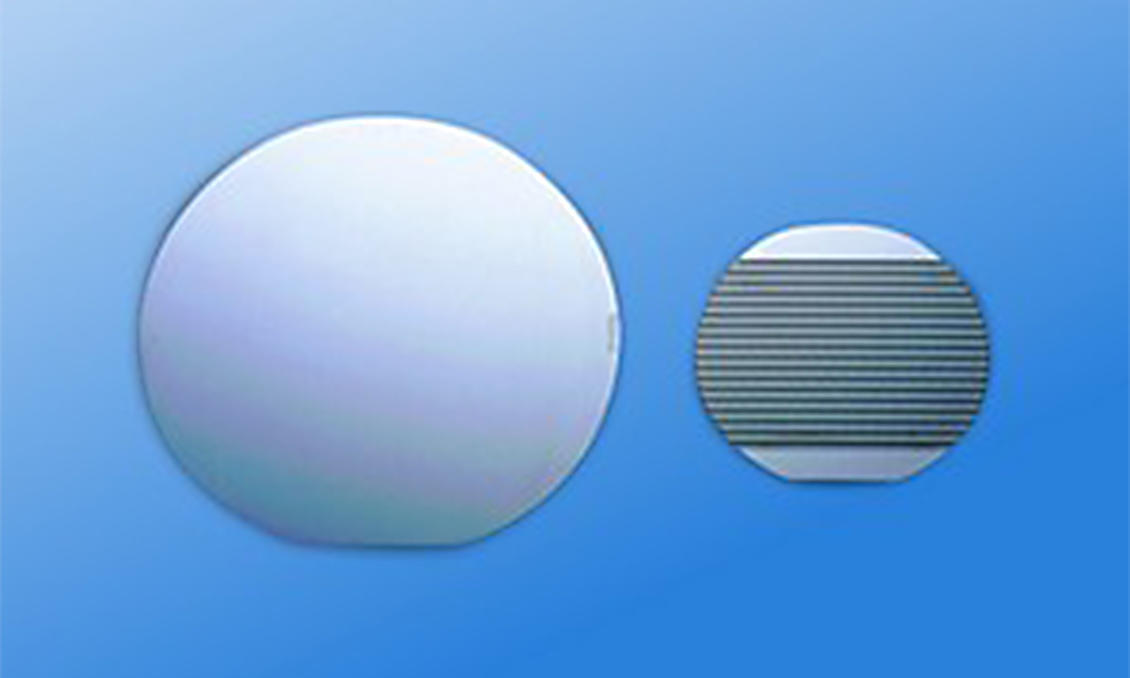

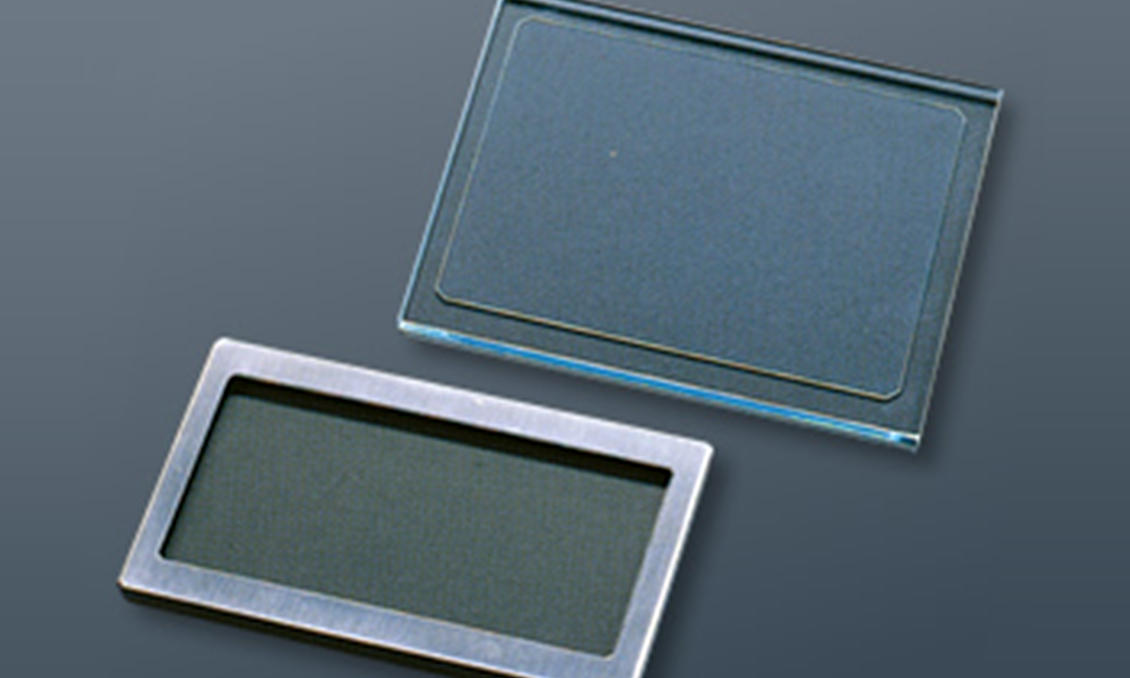

Support Plates for Polarizers in LCD ProjectorsProjector parts utilize sapphire's superior light transmittance and thermal conductivity.

Support Plates for Polarizers in LCD ProjectorsProjector parts utilize sapphire's superior light transmittance and thermal conductivity.- High Thermal Conductivity

- Optical Transparency

-

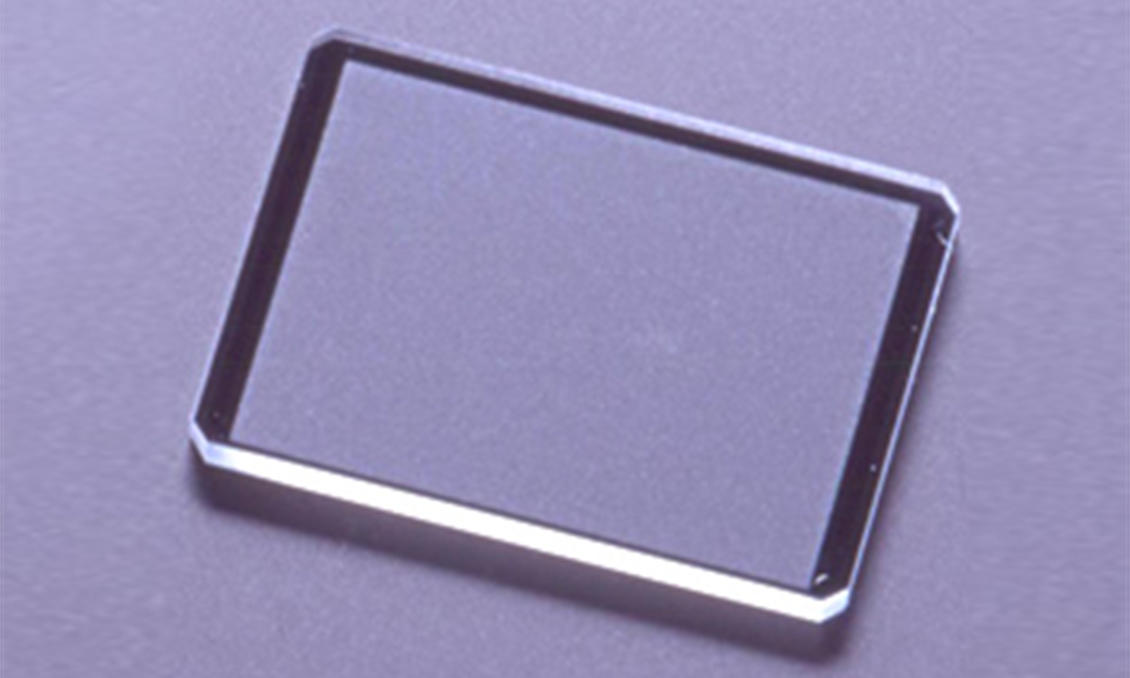

POS Scanner WindowsSuperior hardness and light transmittance greatly improves performance.

POS Scanner WindowsSuperior hardness and light transmittance greatly improves performance.- High Hardness

- Optical Transparency

-

LCD CoversLCD covers utilize the optical and mechanical properties of Kyocera's sapphire material.

LCD CoversLCD covers utilize the optical and mechanical properties of Kyocera's sapphire material.- High Hardness

- Optical Transparency

-

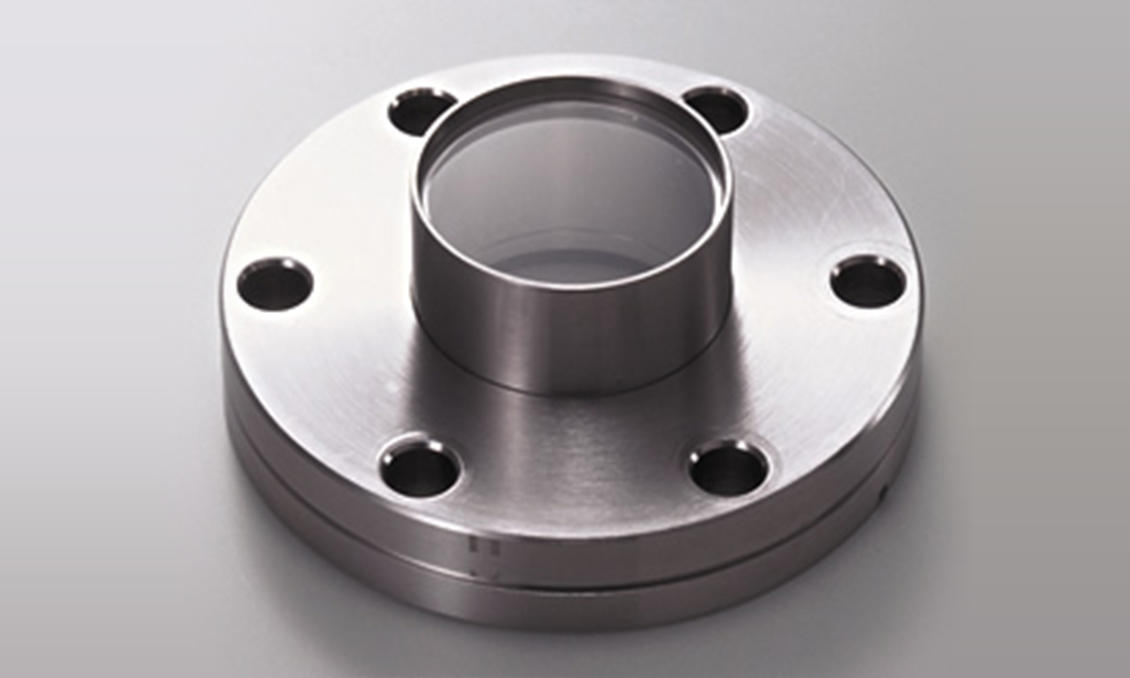

Sapphire Windows with Vacuum FlangeThe combination of our materials and bonding technologies produces sapphire windows with outstanding performance in ultra-high vacuum environments.

Sapphire Windows with Vacuum FlangeThe combination of our materials and bonding technologies produces sapphire windows with outstanding performance in ultra-high vacuum environments.- Airtightness

- Bonding Technology

Customizable

We have a wide range of technologies such as material technology, process technology, design technology, measurement/evaluation technology, and integrated processes from materials to products in-house, so we can respond to various customizations. Please feel free to contact us first.