Ceramic Properties

Mechanical Properties

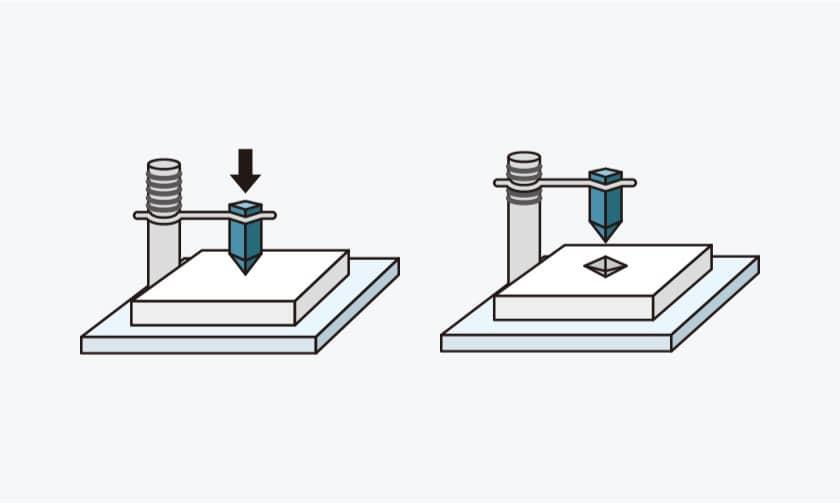

Hardness (Wear Resistance)

The hardness of Fine Ceramics is generally indicated using a Vickers hardness number. The method for measuring the hardness of Fine Ceramics is defined in JIS R 1610 (ISO 14705: 2000). Vickers hardness is a resistance value obtained by pressing a diamond indenter onto a test specimen. Extreme hardness is the primary feature that endows Fine Ceramics with their superior wear resistance. This has led to the use of Fine Ceramics in a wide range of applications, including pump components, cutting tools, seal rings, bearings and a multitude of wear-resistant components for industrial equipment.

| Vickers Hardness HV9.807N GPa |

Material Name & Code | Features | |

|---|---|---|---|

|

High

Low

|

23.0 | Silicon CarbideSiC

SC1000

|

Lightweight, highly corrosion-resistant and excellent heat-resistant material. |

| 22.5

In the case of a-plane

|

SapphireAl2O3

SA100

|

It's a single crystal of alumina, a transparent material. | |

| 15.7 | CermetTiC,TiN

TC030O

|

It is a composite material of TiC or TiN and metal, and has excellent strength and wear resistance. | |

| 15.2 | AluminaAl2O3

AO479O(99%Alumina)

|

It is a widely used material with high electrical insulation and mechanical strength. | |

| 14.0 | Silicon NitrideSi3N4

SN240O

|

This material has excellent heat shock resistance and wear resistance, and has high strength even at high temperatures. | |

| 12.3 | ZirconiaZrO2

ZO201N

|

It is a material with high strength and fracture toughness. | |

| 10.4 | Aluminum NitrideAlN

AN216A

|

It's a material with high thermal conductivity and electrical insulation. | |

| 8.0 | Cordierite2MgO·2Al2O3·5SiO2

CO220O

|

This material has a very low coefficient of thermal expansion and has a small size change due to temperature change. | |

| 7.3 |

Forsterite2MgO·SiO2

F1120O

|

Smooth surface and excellent insulation at high temperature. | |

| 6.0 | YttriaY2O3

YO100A

|

This material has excellent corrosion resistance in a plasma environment. | |

Case studies utilizing this property

-

- Hardness

- High-Temperature Strength

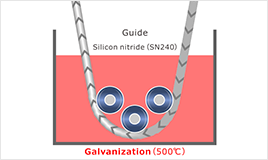

A case of contributing to extending the life of the guide used in the hot-dip galvanization process of steel wire (500℃)Learn More -

- Hardness

- Heat Shock Resistance

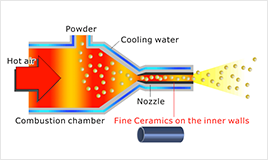

Dramatic increase in life expectancy of nozzles leads to reduced down time of equipmentLearn More -

- Hardness

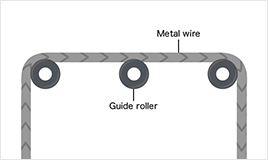

Improving the quality of metal wire, and achieving a lower frequency of replacing rollers.Learn More