Case Studies

Kyocera has contributed to the technological innovation of its customers by providing many creative ceramic components to the world. Here is an example of how we solved a problem by switching from other materials such as metals and resins to fine ceramics.

-

- Chemical Resistance

Example of analysis quality improvement of liquid composition analysis deviceLearn More -

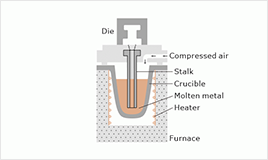

- High-Temperature Strength

- Chemical Resistance

Case Study for Aluminum Casting Part Replacement with Fine Ceramics to Improve Productivity and QualityLearn More -

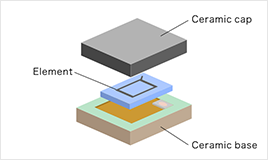

- Stiffness

- Insulation Property

Contributing to the miniaturization of electronic devices by reducing the height and size of gyro sensor capLearn More -

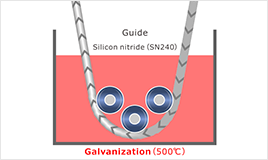

- Hardness

- High-Temperature Strength

A case of contributing to extending the life of the guide used in the hot-dip galvanization process of steel wire (500℃)Learn More -

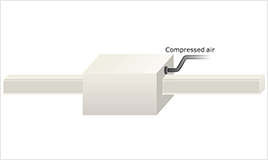

- Stiffness

- Specific Gravity

Improving air slide energy efficiency and precision through the use of Fine CeramicsLearn More -

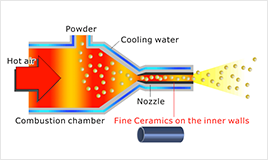

- Hardness

- Heat Shock Resistance

Dramatic increase in life expectancy of nozzles leads to reduced down time of equipmentLearn More -

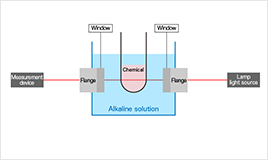

- Chemical Resistance

Improving the chemical resistance of phototransmissive windows for measuring chemical concentrations.Learn More -

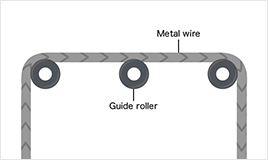

- Hardness

Improving the quality of metal wire, and achieving a lower frequency of replacing rollers.Learn More -

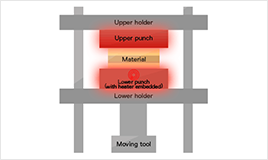

- Thermal Conductivity

- Conefficient of Thermal expansion

Example of improving dimensional accuracy with a zirconia plate of low thermal expansion and thickness tolerance of +/-10 micrometers.Learn More