Product Search by Industries

Semiconductor Processing Equipment

Ceramics are widely used in semiconductor processing equipment where wiring is becoming finer and more multilayered. For lithography equipment, lightweight ceramics with high rigidity are expanding. For etching and deposition equipment, in addition to ceramics with plasma resistance and low particle count, ceramics with heat resistance and low dielectric loss are expanding. For wafer transfer arms, ceramics with high precision and excellent mechanical properties are adopted. Sapphire is used for windows, wafer carrier plates, wafer contact lift pins, plasma introduction tubes, etc. that require optical transparency.

Product examples

-

Fine Cordierite® Low Thermal Expansion MirrorHigh stiffness allows for a thinner and lighter-weight component

Fine Cordierite® Low Thermal Expansion MirrorHigh stiffness allows for a thinner and lighter-weight component- High Stiffness

- Low Thermal Expansion

-

ESD TweezersDeveloped for products and processes sensitive to electrostatic breakdown.

- Semiconductive

- Chemical Stability

-

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.- Design flexibility

- High-Temperature Durability

-

Lamp TubesParts that utilize the light transmittance, heat resistance and insulating properties of sapphire.

Lamp TubesParts that utilize the light transmittance, heat resistance and insulating properties of sapphire.- Heat Resistance

- Insulation Property

-

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.- Heat Resistance

-

Heaters for Semiconductor Processing EquipmentHigh-performance heaters utilize high thermal conductivity and plasma resistance.

Heaters for Semiconductor Processing EquipmentHigh-performance heaters utilize high thermal conductivity and plasma resistance.- High Thermal Conductivity

- Plasma Resistance

-

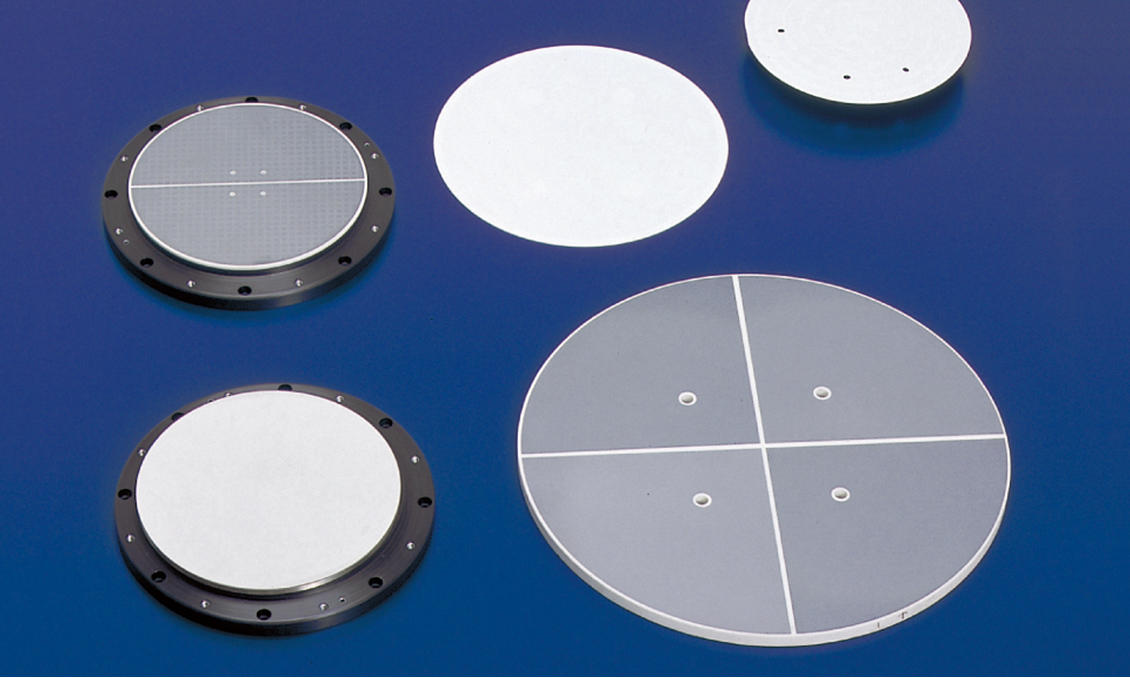

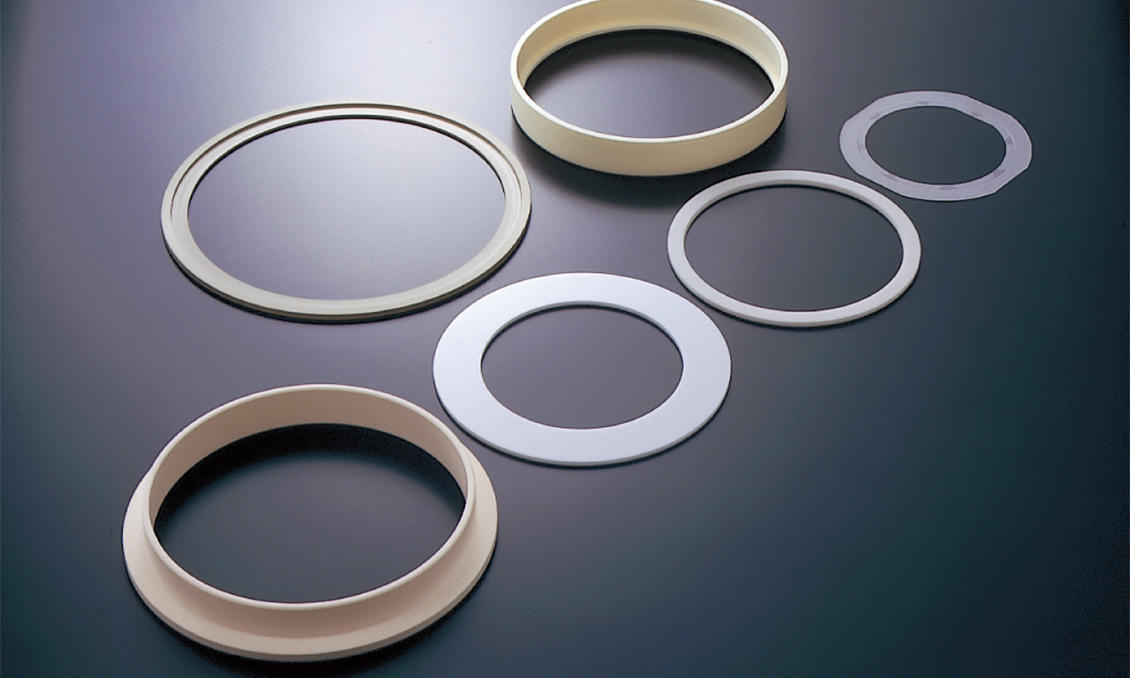

Electrostatic Chucks (ESCs)Highly plasma-resistant chucks perform well in a wide range of operating temperatures.

Electrostatic Chucks (ESCs)Highly plasma-resistant chucks perform well in a wide range of operating temperatures.- Plasma Resistance

-

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.- High Stiffness

- High-Precision

-

Domes, ChambersHigh-purity materials with high durability offer reliable plasma resistance.

Domes, ChambersHigh-purity materials with high durability offer reliable plasma resistance.- Uniform Electrical Properties

- Plasma Resistance

-

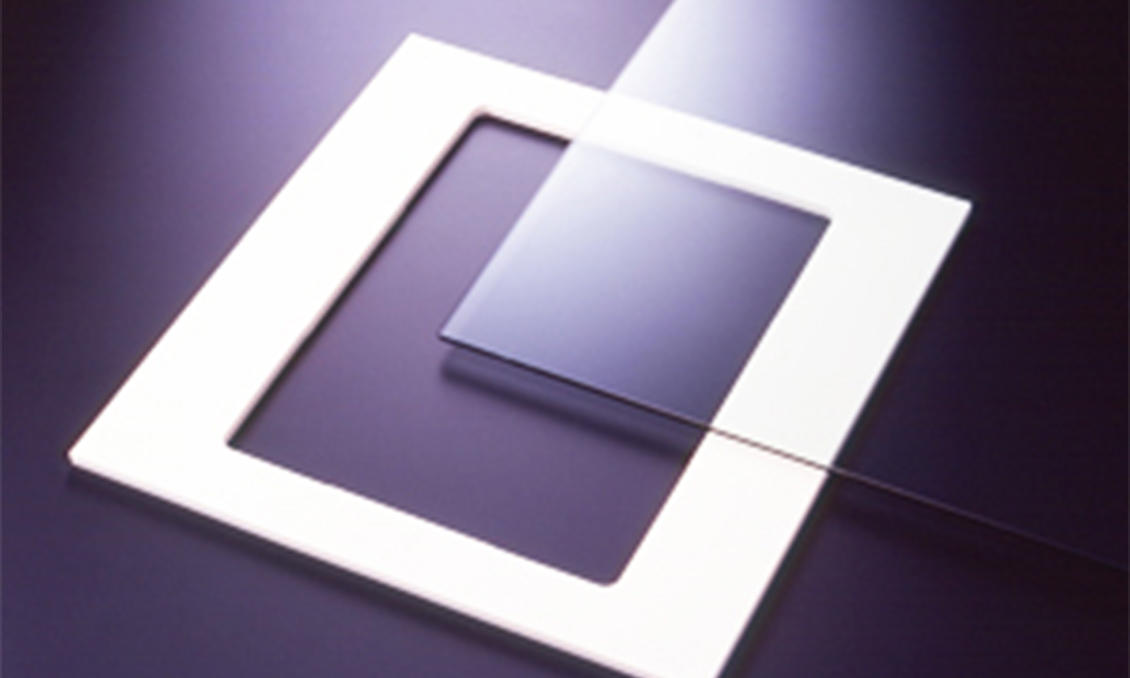

LCD Processing Equipment PartsRigid ceramic parts for liquid crystal display processing equipment.

LCD Processing Equipment PartsRigid ceramic parts for liquid crystal display processing equipment.- High Stiffness

- Low Reflection

-

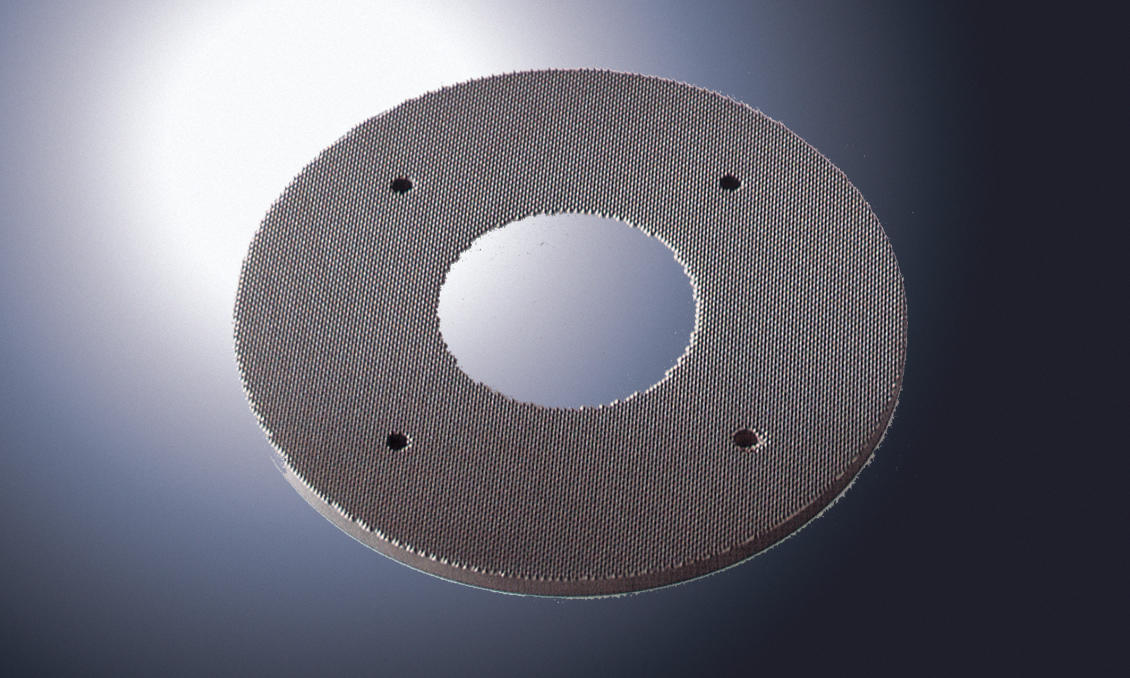

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.- Durability

-

Anti-Plasma MaterialsKyocera's plasma-resistant materials help create the next generation of etching technology.

Anti-Plasma MaterialsKyocera's plasma-resistant materials help create the next generation of etching technology.- Plasma Resistance

- Low Dielectric Loss

-

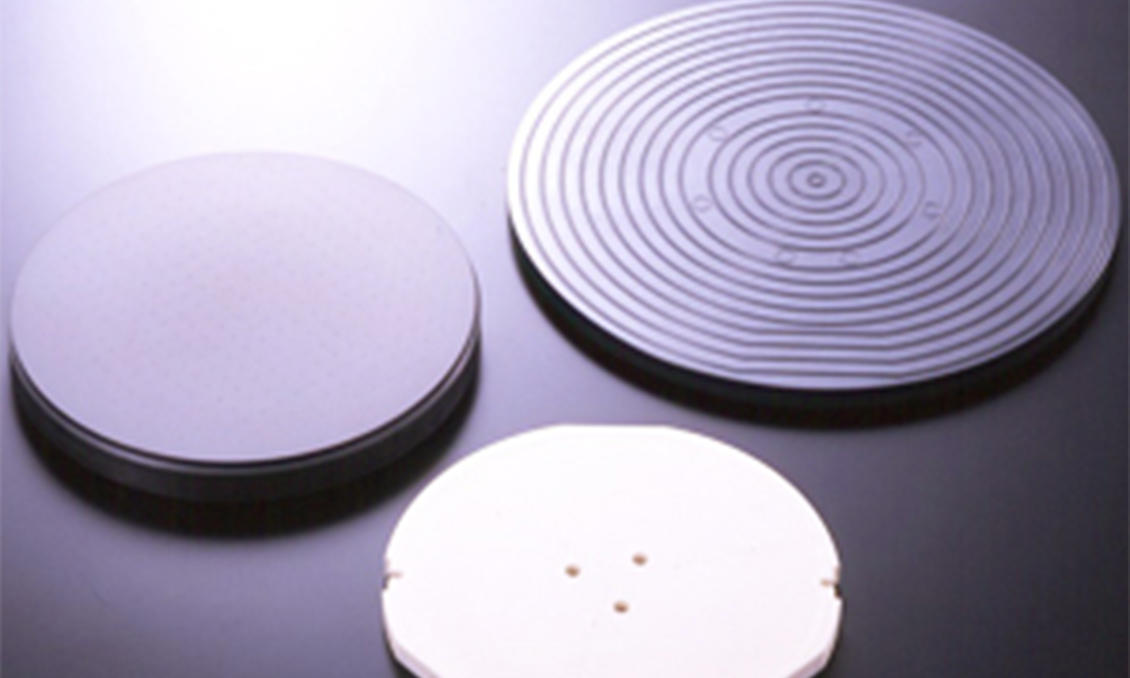

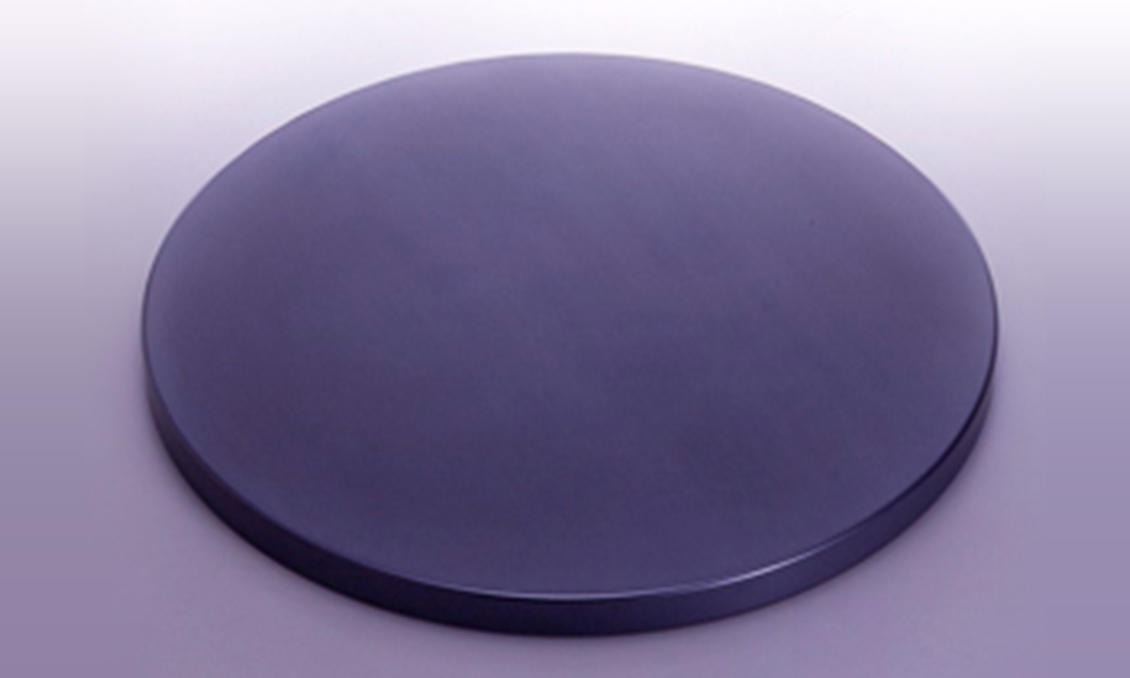

SiC (Silicon Carbide) Polishing PlatesLess deformation through lower thermal distribution. Stronger chemical resistance. A range of surface profiles are available.

SiC (Silicon Carbide) Polishing PlatesLess deformation through lower thermal distribution. Stronger chemical resistance. A range of surface profiles are available.- High Young's Modulus

- Low Thermal Expansion

-

Polishing PlatesHigh-purity alumina ceramics are used for excellent rigidity and wear resistance.

Polishing PlatesHigh-purity alumina ceramics are used for excellent rigidity and wear resistance.- High Hardness

- Wear Resistance

-

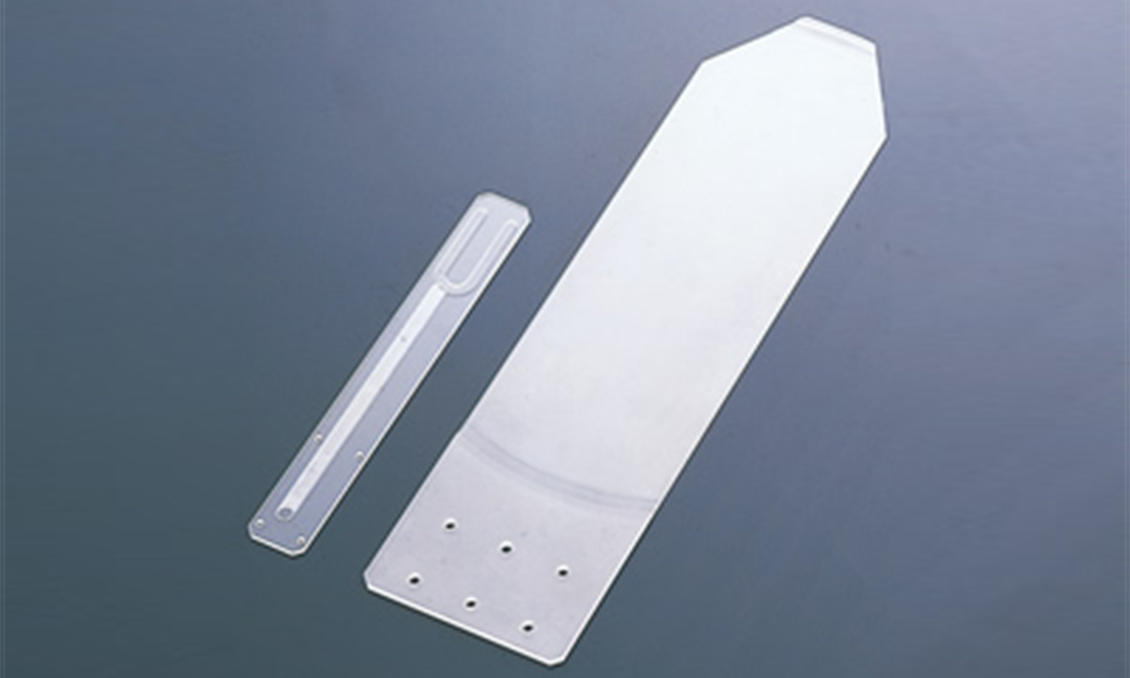

Sapphire Handling Arms (End Effectors)Superior heat resistance and plasma resistance are ideal for semiconductor processing equipment.

Sapphire Handling Arms (End Effectors)Superior heat resistance and plasma resistance are ideal for semiconductor processing equipment.- Heat Resistance

- Plasma Resistance

-

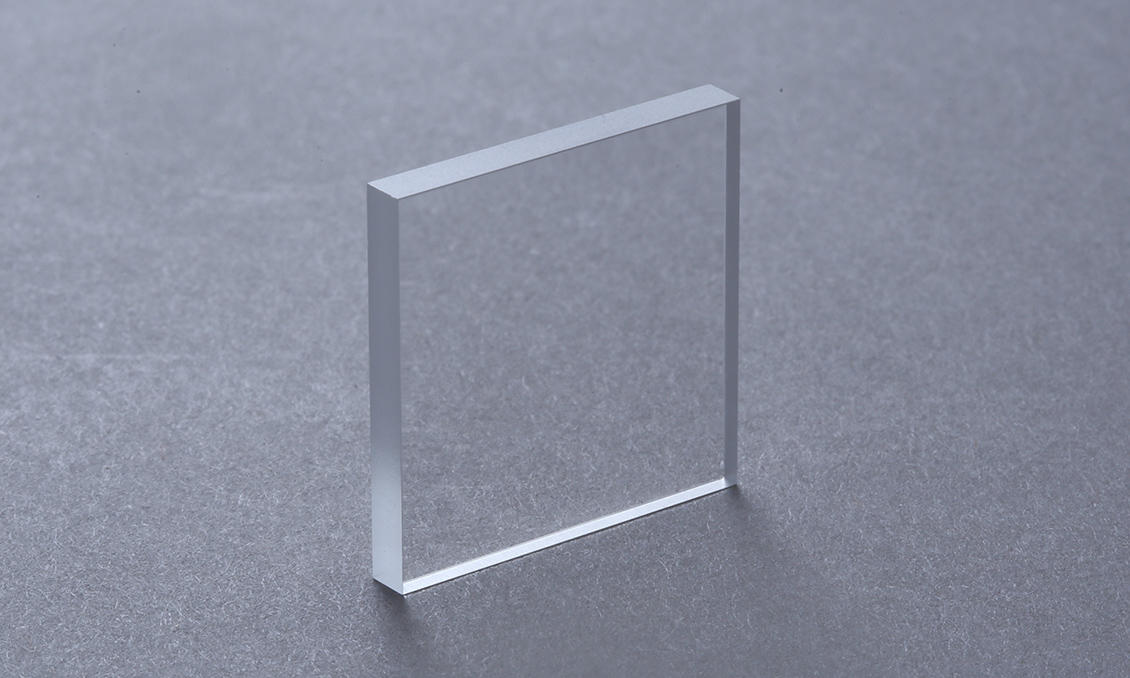

Chamber WindowsKyocera's ultra-pure sapphire is both plasma and heat resistant.

Chamber WindowsKyocera's ultra-pure sapphire is both plasma and heat resistant.- Heat Resistance

- Plasma Resistance

-

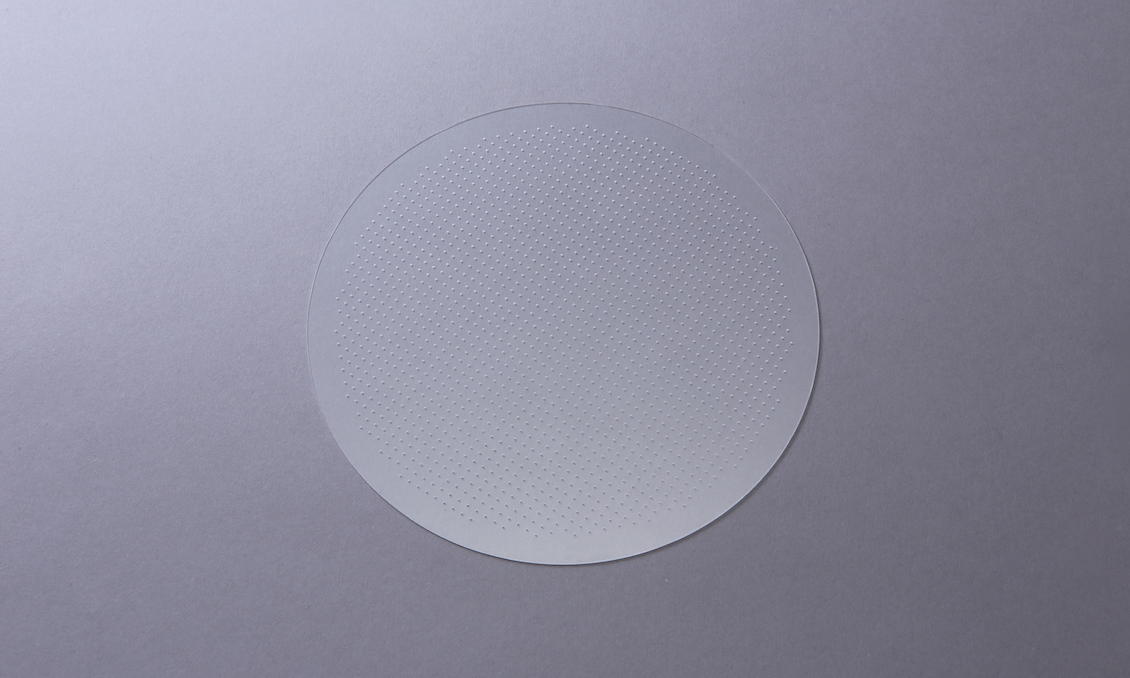

Carrier Plates for GaAs WafersKyocera's ultra-pure sapphire carrier plates for GaAs wafers.

Carrier Plates for GaAs WafersKyocera's ultra-pure sapphire carrier plates for GaAs wafers.- Heat Resistance

- Plasma Resistance

-

Wafer BoatsSemiconductor processing equipment utilizes sapphire's plasma- and heat-resistant properties.

Wafer BoatsSemiconductor processing equipment utilizes sapphire's plasma- and heat-resistant properties.- Heat Resistance

- Plasma Resistance

-

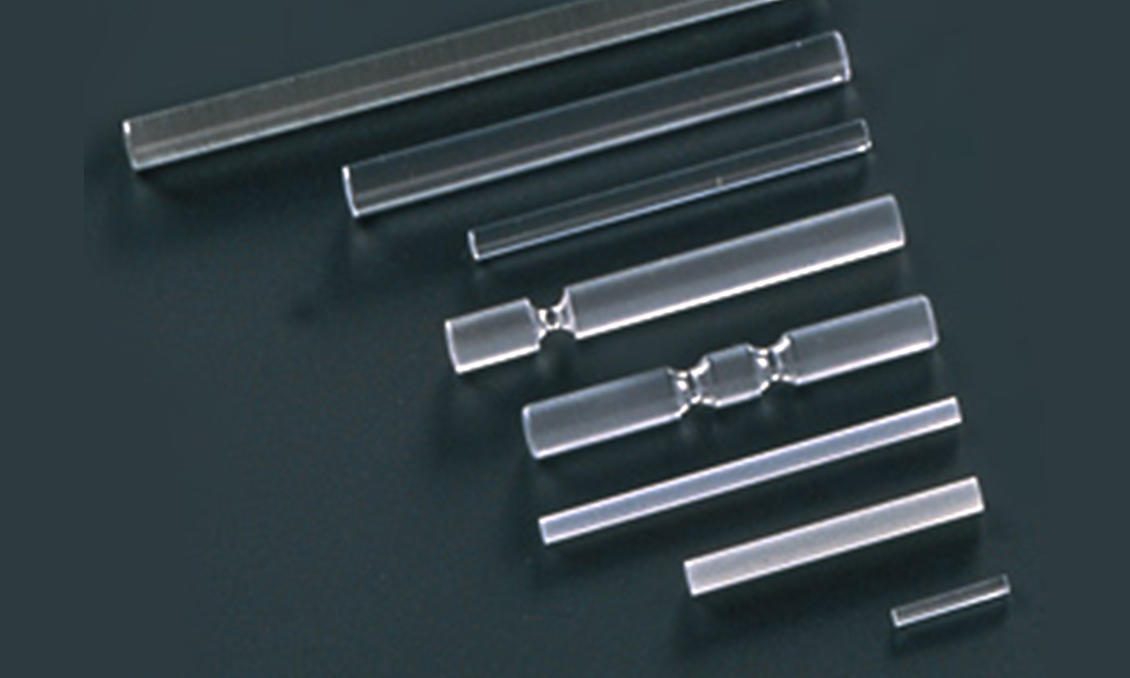

Lift PinsKyocera's ultra-pure sapphire lift pins.

Lift PinsKyocera's ultra-pure sapphire lift pins.- Heat Resistance

- Plasma Resistance

-

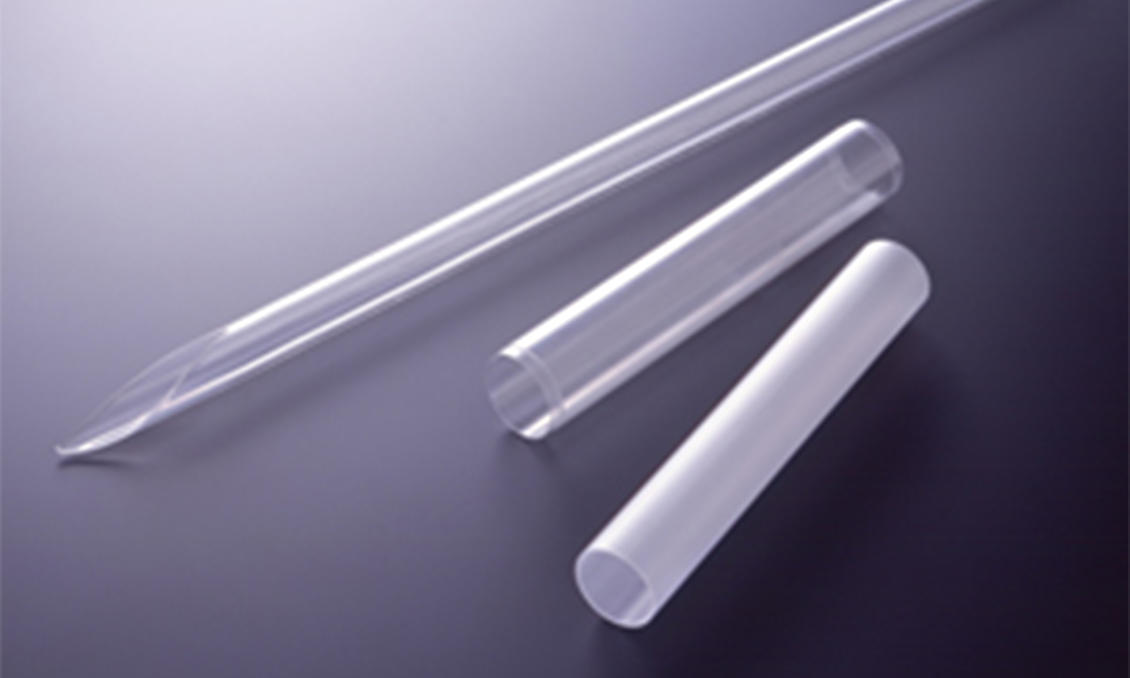

Plasma Generation, Introduction Tubes, Microwave Introduction TubesTube-shaped parts exhibit superior plasma resistance and low dielectric loss.

Plasma Generation, Introduction Tubes, Microwave Introduction TubesTube-shaped parts exhibit superior plasma resistance and low dielectric loss.- Heat Resistance

- Plasma Resistance

-

Feedthroughs (Multi-pin)Multi-pin terminal feedthroughs are based on advanced ceramic-to-metal bonding technology.

Feedthroughs (Multi-pin)Multi-pin terminal feedthroughs are based on advanced ceramic-to-metal bonding technology.- Airtightness

- Bonding Technology

-

Feedthroughs (Coaxial)Used in a wide range of applications, from radiation light sources and nuclear science to industrial equipment.

Feedthroughs (Coaxial)Used in a wide range of applications, from radiation light sources and nuclear science to industrial equipment.- Airtightness

- Bonding Technology

-

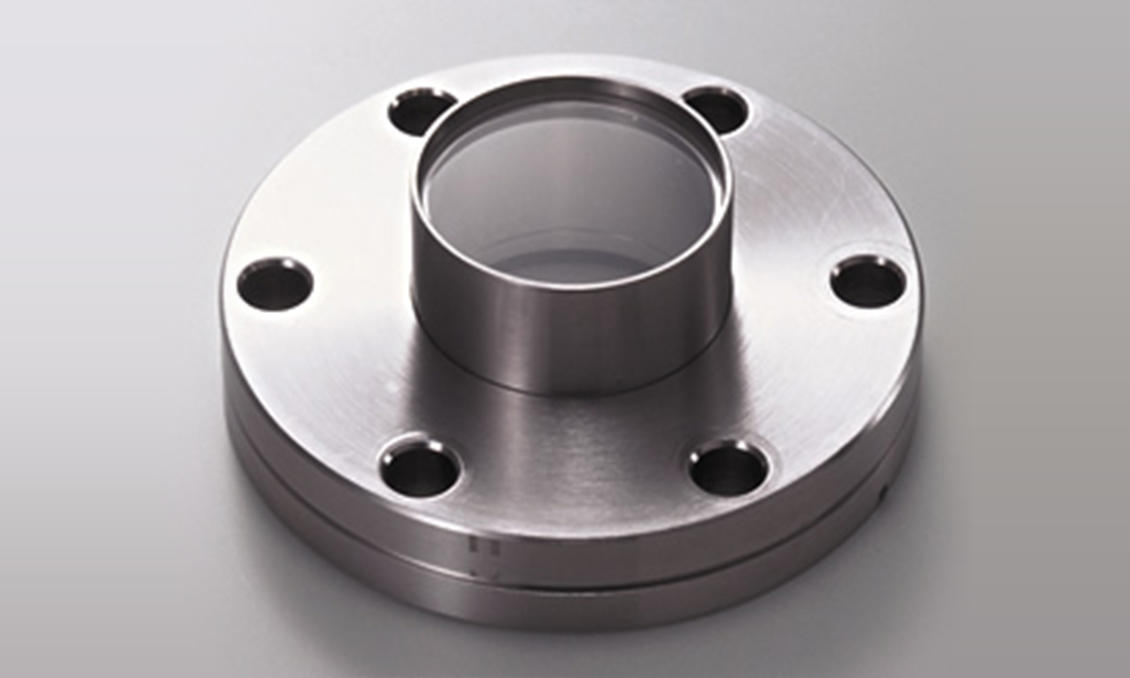

Isolator FlangesCeramic isolator flanges used in advanced experimental laboratories.

Isolator FlangesCeramic isolator flanges used in advanced experimental laboratories.- Airtightness

- Bonding Technology

-

FeedthroughsHighly reliable feedthroughs are proven components in a range of industrial sectors.

FeedthroughsHighly reliable feedthroughs are proven components in a range of industrial sectors.- Airtightness

- Bonding Technology

-

Sapphire Windows with Vacuum FlangeThe combination of our materials and bonding technologies produces sapphire windows with outstanding performance in ultra-high vacuum environments.

Sapphire Windows with Vacuum FlangeThe combination of our materials and bonding technologies produces sapphire windows with outstanding performance in ultra-high vacuum environments.- Airtightness

- Bonding Technology

-

Hermetic Subminiature D type Ceramic FeedthroughsSubminiature D type Ceramic Feedthroughs have good hermetic properties for Ultra High Vacuum Application.

Hermetic Subminiature D type Ceramic FeedthroughsSubminiature D type Ceramic Feedthroughs have good hermetic properties for Ultra High Vacuum Application.- Insulation Property

- Airtightness

-

Special Brazed FeedthroughsBrazed with aluminum or non-magnetic metals is available.

Special Brazed FeedthroughsBrazed with aluminum or non-magnetic metals is available.- High Thermal Conductivity

- Insulation Property

-

Vacuum Interrupter Ceramic TubeCeramic Insulator Tubes are used in vacuum interrupters for medium voltage switch gear (approx. 6kV to 80kV).

Vacuum Interrupter Ceramic TubeCeramic Insulator Tubes are used in vacuum interrupters for medium voltage switch gear (approx. 6kV to 80kV).- Insulation Property

- Airtightness

Customizable

We have a wide range of technologies such as material technology, process technology, design technology, measurement/evaluation technology, and integrated processes from materials to products in-house, so we can respond to various customizations. Please feel free to contact us first.