Single-crystal sapphire is a transparent ceramic material with high hardness, strength, rigidity, wear resistance, heat resistance, and plasma resistance, in addition to outstanding optical transparency. Processing single-crystal sapphire is extremely difficult and requires a high level of processing technology.

Over 50-plus years in of processing expertise, Kyocera has accumulated expertise in optical-level lapping and polishing for sapphire wafer shapes, complex shapes (such as rings), grooves, uneven surfaces, spheres, and curved surfaces.

Features

- Capable of Lapping and Polishing Complex Shaped Sapphire Products

Lapping and polishing possible for various shapes, such as rings, grooves, uneven surfaces, spheres, and curved surfaces. - Lapped and Polished Surfaces are Smooth

Outstanding optical transmittance is possible by surface roughness of Ra ≤ 0.05 μm - Low Particulates

High-precision surface finishing reduces particle generation (dust generation).

Application Examples

Due to their superior material properties, single-crystal sapphire parts are being used more frequently in applications with harsh environments, such as semiconductor manufacturing equipment, automobile/mobility, industrial machinery, and aerospace/astronomy.

Kyocera can manufacture from large diameter and long sapphire materials and single-crystal sapphire that does not fluoresce under lasers.

We also have extensive experience mirror polishing complex shaped products, including large single-crystal sapphire rings.

-

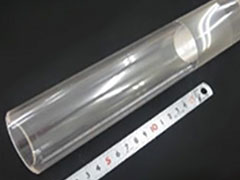

Plasma Tube

Φ30 × φ25 × 250L (mm)

-

Sensor Window

Φ5 × φ3 × 70L (mm)

-

Cylinder

Φ100 × φ80 × 150L (mm)

-

Sensor Lens

Φ50 × 30H (mm) hollow

-

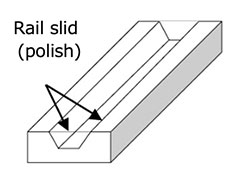

Guide Rail

Groove: 5 (width) x 3 (depth) x 10L (mm)

-

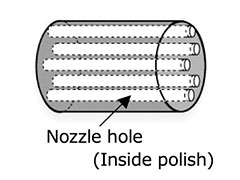

Gas and Fluid Nozzles

Flow channel diameter: φ4 × 50L (mm)

*Above numbers are processing examples

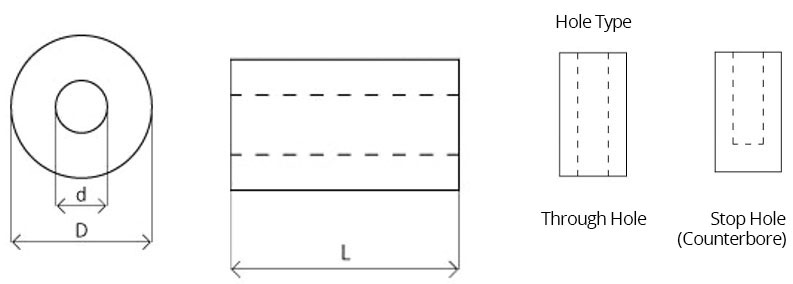

Design Guide

| Standard Specifications | ||

|---|---|---|

| Material | Single-Crystal Sapphire | |

| Material Code | SA100 | |

| Full Length | (L) | - 500 [mm] |

| Outer Diameter | (ΦD) | 5.0 - 100.0 [mm] |

| Inner Diameter | (Φd) | 2.0 - 80.0 [mm] |

*Refer to the following figures for dimensions in parentheses.

Lapping and Polishing Evaluation

We develop single-crystal sapphire with outstanding optical transmittance by improving the level of lapping and polishing of the finished surface.

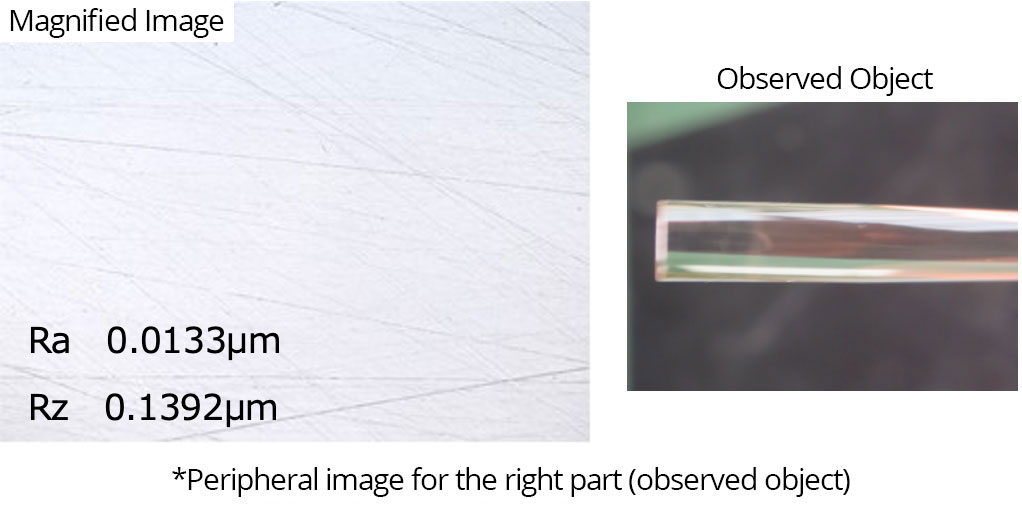

Surface Roughness

Observation image of finished surface by a laser microscope

Observation

Image

(x1,200)

*Characteristics vary depending on orientation and thickness

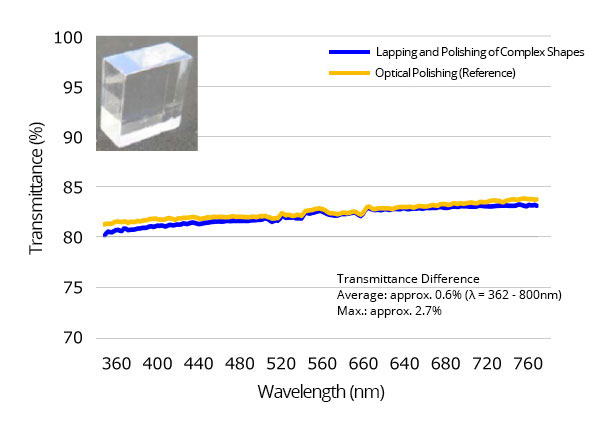

Transmittance

Visible light transmittance of lapped and polished complex surface and optical polished surface measured by a spectrophotometer

*Without AR coating.

*The data are reference values and do not guarantee the characteristics of the product.

*Characteristics vary depending on orientation and thickness.

Property Data Comparison

Comparison of main properties of single-crystal sapphire and transparent materials

| Material Material Code |

Sapphire SA100 |

Quartz Glass | Glass | |||

|---|---|---|---|---|---|---|

| Melting Point | ℃ | 2053 | 1600 | 720 | ||

| Vickers Hardness HV9.807N | GPa | 22.5 | 8.8 | 5.4 | ||

| Flexural Strength (3-Point Bending) | MPa | 690 | 68.6 | 49.0 | ||

| Young's Modulus | GPa | 470 | 73 | 72 | ||

| Thermal Conductivity | 20℃ | W/(m・K) | 42 | 1.2 | 0.8 | |

| C.T.E. | 40-400℃ | × 10-6/K | Parallel to the C-axis | 7.7 | 0.51 (RT -100℃) |

8.5 |

| Perpendicular to C-axis | 7.0 | |||||

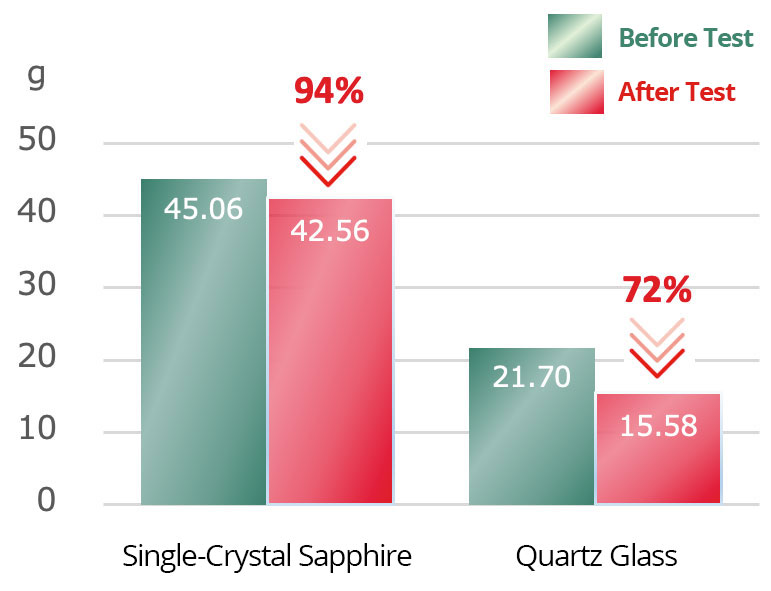

Plasma Resistance

Single-crystal sapphire has outstanding plasma resistance.

It suppresses particle generation (dust generation) and is effective in reducing contamination by impurities.

For these reasons, single-crystal sapphire is used for windows and parts of sputtering equipment, CVD equipment, and etching equipment.

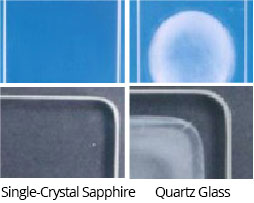

Corrosion resistance test of single-crystal sapphire and quartz glass

Etching Rate

Measurement Condition

| Size : | φ150mm |

| Reactant Gas : | Chlorine Trifluoride (CIF3) |

| Time : | 270 hours |

Corrosion resistance test results

*State after one month of use under reactant gas

Measurement Condition

| Reactant gas : | Mixed gas of tetrafluoromethane (CF4) + oxygen(O2) |

| Time : | 1 month |

Are you looking for materials with high hardness or high wear resistance to replace quartz glass? Kyocera develops single-crystal sapphire for harsh environments, such as astronomy, aerospace, and chemical handling. We also help decrease maintenance costs and increase the lifespan for replacement parts.

Contact us for a free consultation with one of our product solution experts.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.