50% size reduction and 1.6 times higher voltage resistance compared to conventional ceramic (based on Kyocera simulation).

Alumina ceramics, which have high dielectric resistance characteristics, are widely used in high-voltage devices.

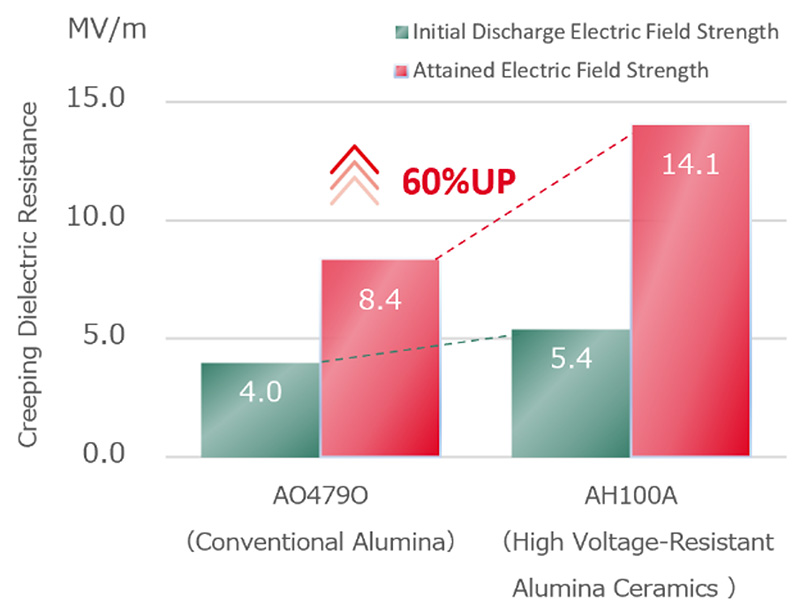

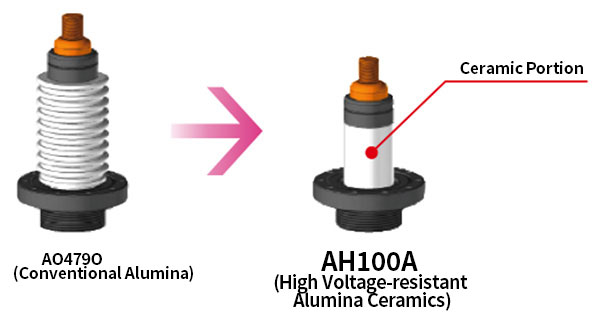

Kyocera has developed the new material AH100A with improved creeping dielectric resistance performance.

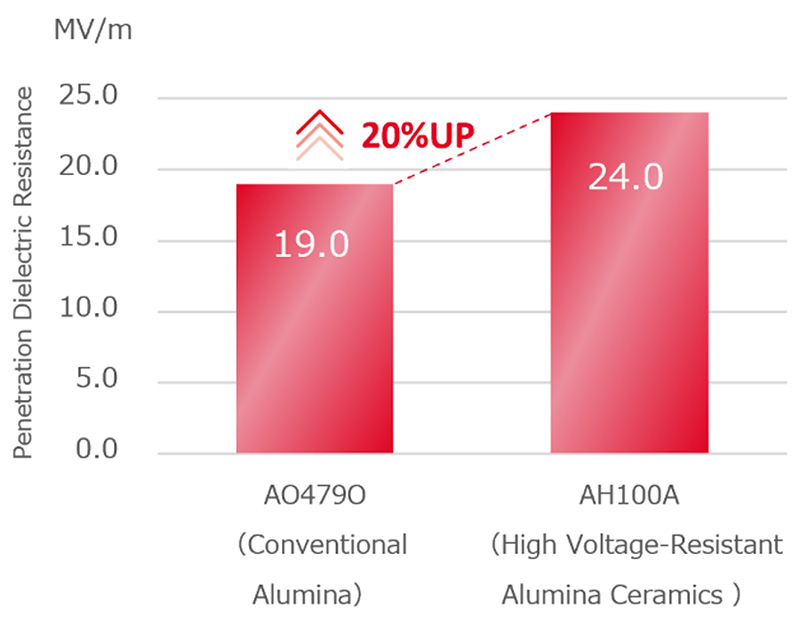

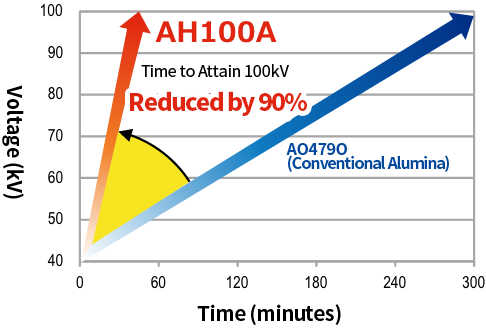

AH100A has 1.6 times higher creeping dielectric resistance and 1.2 times higher penetration dielectric resistance compared to conventional ceramics. This makes it possible to reduce high-voltage conditioning time and miniaturize terminals.

Features

- Significantly improved creeping dielectric resistance and penetration dielectric resistance in vacuum atmosphere.

- Significant reduction of high voltage conditioning time

- 50% size reduction compared to conventional alumina (based on Kyocera simulation)

Creeping Dielectric Resistance

Measurement Conditions

Creeping dielectric resistance distance: 2 mm

Measurement atmosphere: 10 Pa or less

Other measurement conditions of Kyocera

Penetration Dielectric Resistance

Measurement Conditions

2mm thickness

Other measurement conditions of Kyocera

Conditioning Time

Measurement Conditions

Pressure: 10-3 Pa or less

Boost Voltage: 1kV/min.

When flashover occurs, the voltage rises again from 0 volts

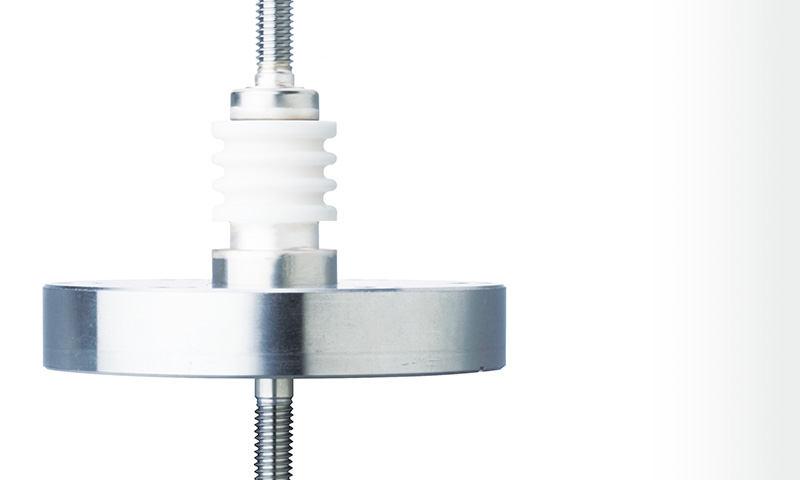

Image of New Compact Design

Weight: 55% less

Material Data Comparison

| Material Material Code |

High Voltage-resistant Alumina Ceramics | (Conventional) Alumina | |||

|---|---|---|---|---|---|

| AH100A | AO479O | ||||

| Electrical Characteristics | Attained Electric Field Strength | MV/m | 14.1(ave.) | 8.4(ave.) | |

| Penetration Dielectric Resistance | MV/m | 24 | 19 | ||

| Volume Resistivity | 20℃ | Ω・cm | ≧1014 | >1014 | |

| Dielectric Constant (1MHz) | - | 10.2 | 9.9 | ||

| Dielectric Loss Angle (1MHz) | (x 10-4) | <1 | 2 | ||

| Mechanical Characteristics | Flexural Strength (3-point Bending) | MPa | 330 | 310 | |

| Young's Modulus of Elasticity | GPa | 380 | 360 | ||

| Poisson's Ratio | - | 0.25 | 0.23 | ||

| Fracture Toughness (SEPB) | MPa・m1/2 | 5 | 3~4 | ||

| Thermal Characteristics | Thermal Conductivity | 20℃ | W/(m・K) | 24 | 29 |

| Coefficient of Linear Thermal Expansion (RT-800℃) | × 10-6/K | 8.2 | 8.0 | ||

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.