Improvement and Optimization of Material Performance

ZTA (Zirconia Toughened Alumina) is a composite material made from alumina and zirconia. It combines the outstanding characteristics of both materials.

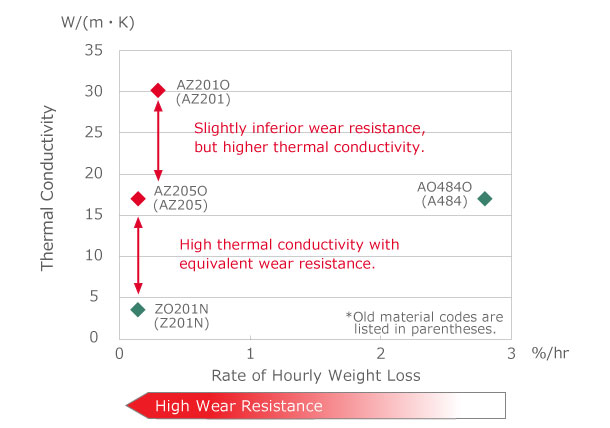

Compared to conventional alumina, ZTA possesses superior hardness, higher flexural strength, and similar density. Compared to conventional zirconia, it possesses a lower coefficient of linear thermal expansion and higher thermal conductivity.

By leveraging these features, ZTA has been widely adopted in milling parts and wear-resistant parts that require cooling.

Features

- High Stiffness and Outstanding Wear ResistanceStiffer than alumina with outstanding wear resistance equivalent to zirconia.

- High Thermal Conductivity and Low Thermal ExpansionSuppresses thermal deformation through thermal conductivity and low thermal expansion equivalent to alumina. Suitable for components requiring a cooling Mechanism.

- High Strength and Specific RigidityApproximately twice as strong as alumina and contributes to low-weight design through high specific rigidity.

Specifications

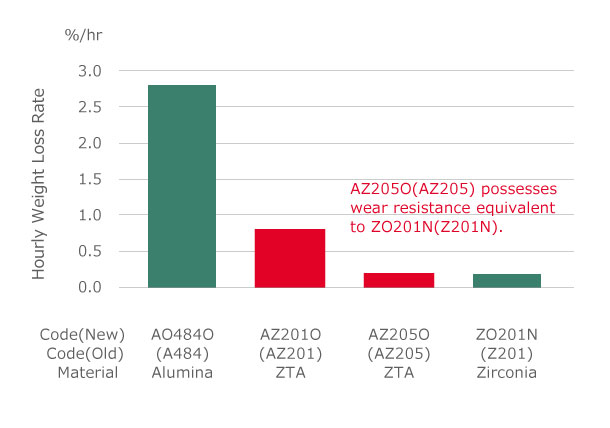

Wear Resistance Test (Wet Grinding)

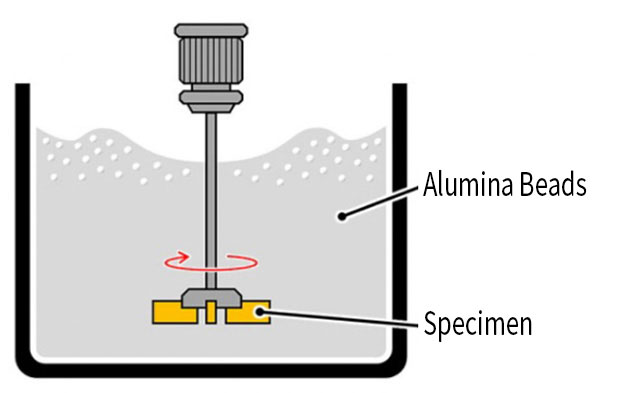

Slurry Wear Resistance Test

Test Conditions

-

(1) Rotational Speed :1,750 rpm

-

(2) Test Duration :10 hours

-

(3) Test Material :Alumina Beads Φ1mm

-

(4) Loading Amount :Alumina Beads / Water

2kg/4kg (11.4 vol.%)

-

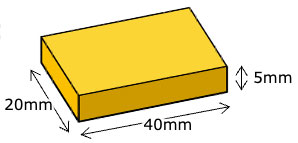

(5) Samples :

Comparison of Wear Resistance and Thermal Conductivity

Material Data Comparison

| Material Material Code |

ZTA | Alumina | Zirconia | Stainless Steel | |||||

|---|---|---|---|---|---|---|---|---|---|

| AZ201O (AZ201) |

AZ205O (AZ205) |

AO479M (A479M) |

AO484O (A484) |

ZO201N (Z201N) |

SUS304 | ||||

| Alumina Content | % | - | - | 99.5 | 92 | - | - | ||

| Color | - | White | White | Ivory | White | Ivory | - | ||

| Density | g/cm3 | 4.0 | 4.3 | 3.9 | 3.6 | 6.0 | 7.9 | ||

| Mechanical Characteristics | Vickers Hardness HV9.807N | GPa | 17.0 | 16.0 | 15.7 | 12.3 | 12.3 | - | |

| Flexural Strength (3-point Bending) | MPa | 700 | 700 | 370 | 370 | 1,000 | - | ||

| Young’s Modulus | GPa | 380 | 335 | 370 | 280 | 200 | 193 | ||

| Poisson’s Ratio | - | 0.24 | 0.25 | 0.23 | 0.23 | 0.31 | 0.29 | ||

| Thermal Characteristics | Coefficient of Linear Thermal Expansion | 40~400℃ | × 10-6/K | 7.2 | 7.7 | 7.2 | 6.8 | 10.5 | 10.9 |

| 40~800℃ | 8.1 | 8.7 | 8.0 | 7.7 | 11.0 | - | |||

| Thermal Conductivity | 20℃ | W/ (m・K) | 30 | 17 | 32 | 17 | 3 | 16.7 | |

| Specific Heat Capacity | J/ (g・K) | 0.77 | 0.72 | 0.78 | 0.78 | 0.46 | 0.50 | ||

Example of Size for Manufactured Products

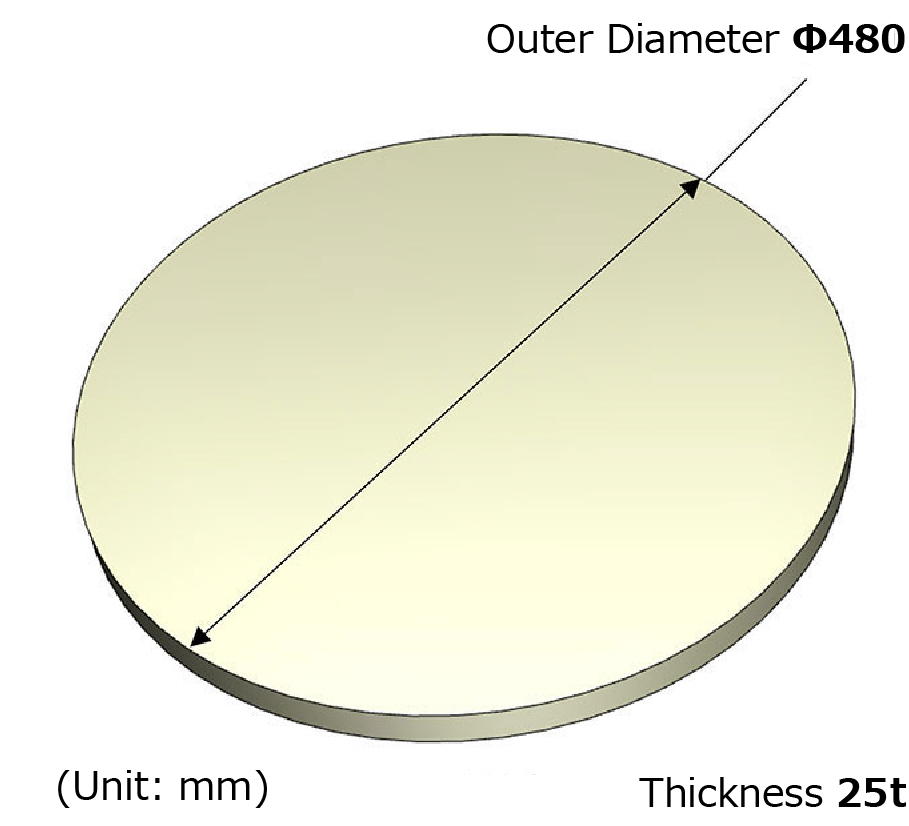

Disc Shape

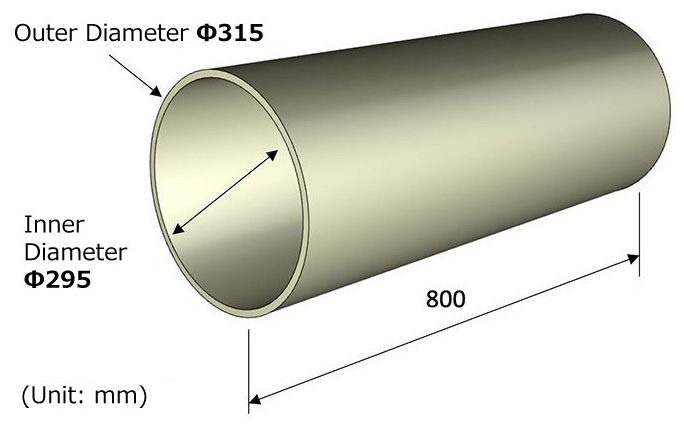

Cylindrical Shape

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.