Alumina multi-layer diffusion bonding is a bonding technology, which enables us to make unified alumina products by stacking thin alumina plates without the use of adhesives. With this technology, it's possible to make liquid mixing components with internal channels and complex external geometries that are difficult to make from one ceramic body.

Bonding sintered ceramics together avoids any distortion caused by shrinkage and provides greater dimensional accuracy than raw bonding (tolerance ranges from a few 10 microns / depending on geometry).

Features

- Less generation of impurities and particles

No adhesives are used which reduces the generation of impurities and particles from the bonding surface. - High Heat Resistance

Since no adhesives are used, the high heat resistance inherent in ceramics can be demonstrated.

*Please consult with us for details as it depends on the conditions of use. - Internal channels and complex external shapes can be realized

By integrating multiple alumina parts, internal channels and complex external shapes can be created. - High airtightness

Diffusion bonding technology enables high vacuum requirements of less than 10-9 Pa・m3/s in He leakage tests.

Bonding Example

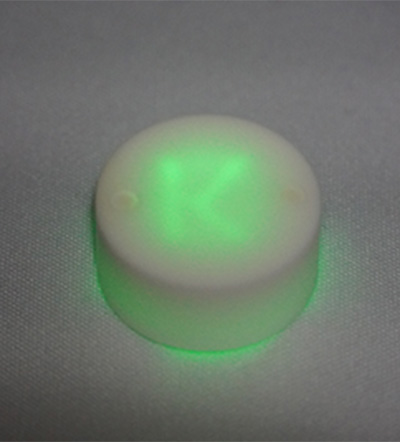

A sample of 20 stacked alumina parts, 30 mm in diameter × 0.3 mm thick.

Before bonding

Flow path patterns are formed on each component

After bonding

Light transmitted through backside

- No internal defects were confirmed by X-ray CT analysis.

- Less than 10-9 Pa・m3 /s leakage was confirmed through He leakage tests.

- Up to 95 pieces have been bonded.

Application Example

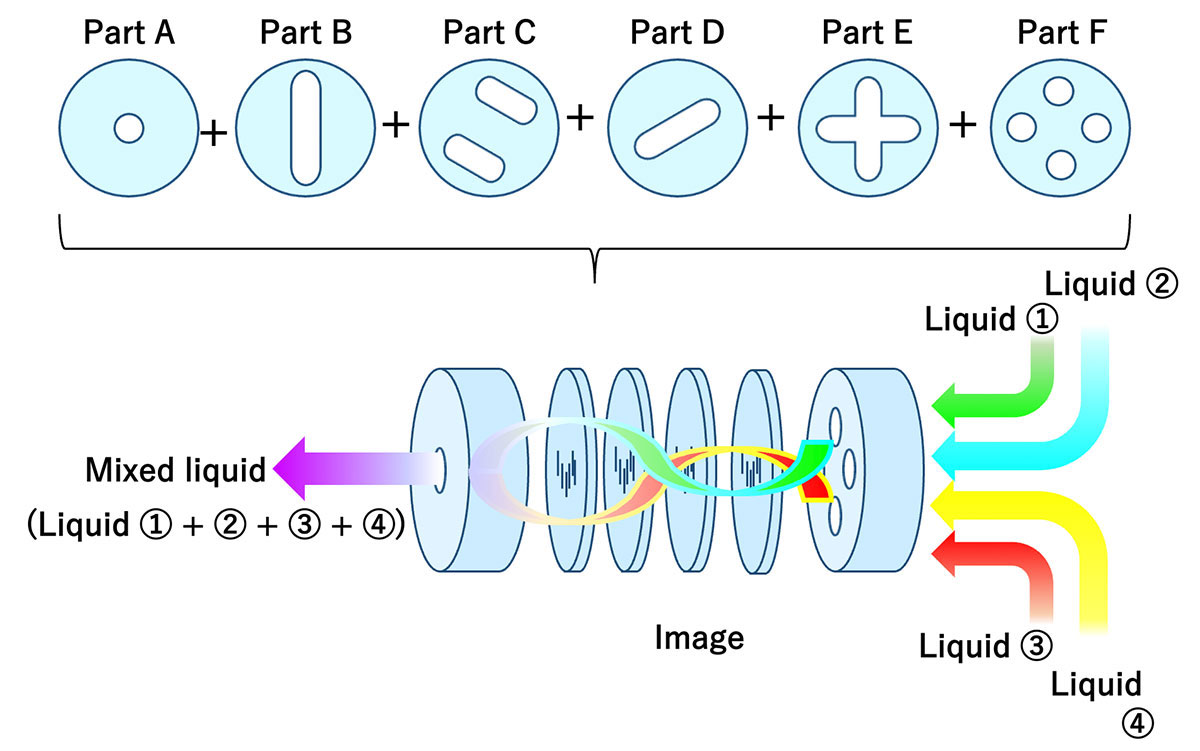

Formation of internal flow path patterns

Internal channels can be formed by diffusion bonding of each alumina component with flow path patterns.

Example: liquid mixing component

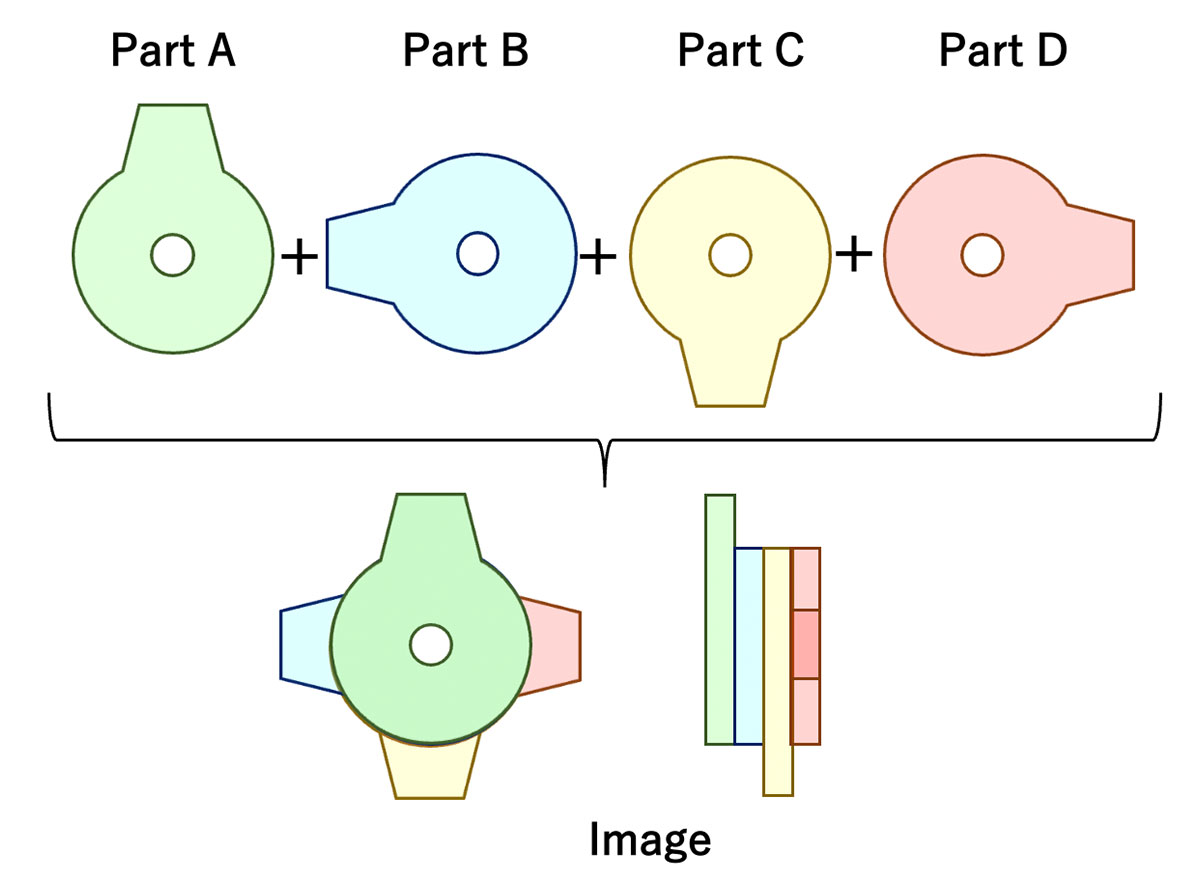

Formation of external shape

By utilizing lamination technology, it is possible to create complex external shapes that cannot be machined by a single ceramic blank material.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.