Expands design flexibility by bonding (adding) instead of removal machining (subtracting)

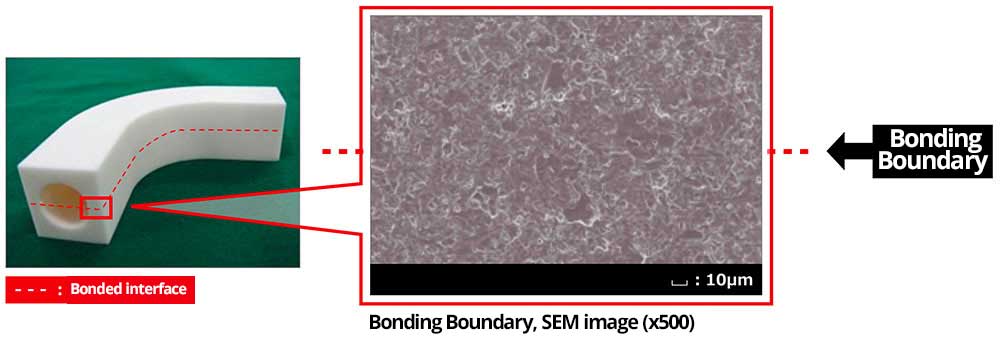

This new technology is a processing method whereby two or more green bodies are stacked, sintered, and bonded together into a monolithic body. Since the interfaces of the green bodies are sintered, it makes a dense boundary. The strength of bonded parts ends up equivalent to the bulk parts.

Features

- Enables Shapes Difficult to Achieve with MachiningThis bonding method allows for more complex shapes, where the tools of conventional machining cannot reach physically.

- Superior Design FlexibilityFlexible design by bonding (adding) instead of removal machining (subtracting)

- Unified Bonding BoundaryDense and highly reliable bonding technology with no loss of mechanical strength or thermal conductivity.

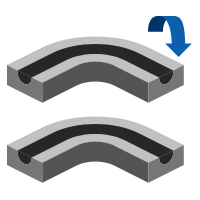

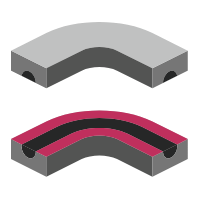

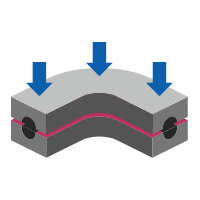

Manufacturing Process

Machine the pre-sintered green bodies. Align the surfaces where the bonding agent is applied, and bond by sintering under load. Then grind to the final shape.

-

Green Machining

Green bodyGreen body

-

Apply bonding agent

Prepare bonding agent

-

Align the Joint surface

Load

-

SinteringGrinding

- mix boding agent

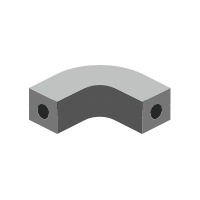

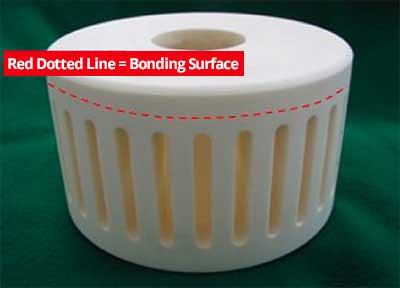

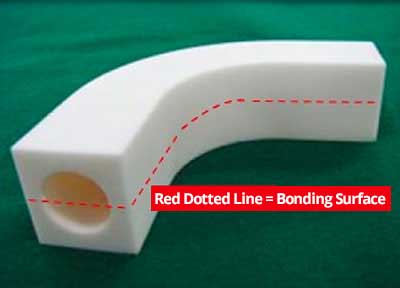

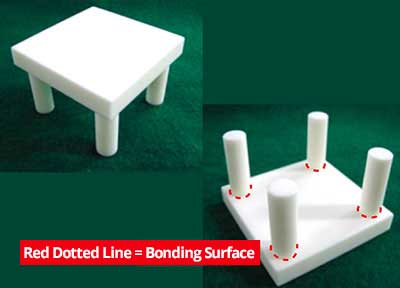

Design Samples

Complex internal shapes that are impossible to grind with tools from the outside are possible. In addition, some shapes which were conventionally achieved by machining a large portion of bulk body, for example, shapes with protrusions, can be formed by bonding, which will prevent material loss and will also reduce production time.

Samples

-

Rotor

Φ160 x 95t (mm)

-

Internal Channel

Φ100 x 20t (mm)*Cut model for reference of internal structure.

-

Bent Pipe

Φ200 x 200 x 30t (mm)

-

Table

60 x 40t (mm)

Unified Bonding Boundary

SEM image

(x500)

Ceramics at bonding boundary also become dense.

Material Lineup

| Material Material Code |

Alumina | Cordierite | Silicon Carbide | |||

|---|---|---|---|---|---|---|

| AO479M | CO220O | SC120O | ||||

| Color | - | Ivory | Gray | Black | ||

| Density | g/cm3 | 3.9 | 2.5 | 3.15 | ||

| Mechanical Characteristics | Vickers Hardness HV9.807N | GPa | 15.7 | 8.0 | 23.0 | |

| Flexural Strength (3-point Bending) | MPa | 370 | 190 | 500 | ||

| Young’s Modulus | GPa | 370 | 140 | 430 | ||

| Poisson’s Ratio | - | 0.23 | 0.31 | 0.16 | ||

| Thermal Characteristics | Coefficient of Linear Thermal Expansion | 40-400℃ | × 10-6/K | 7.2 | (*) 1.5 | 3.7 |

| 40-800℃ | 8.0 | (*) 2.1 | 4.4 | |||

| Thermal Conductivity | 20℃ | W/ (m・K) | 32 | 4 | 190 | |

| Specific Heat Capacity | J/ (g・K) | 0.78 | 0.71 | 0.67 | ||

(*) <|0.05|(23℃)、<|0.02|(22℃)

Green Bonding processes of Cordierite and Silicon Carbide are under development. Please feel free to contact us for more details.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.