High-Precision Laser Processing Technology

Kyocera offers laser processing, which enables small-lot production using CAD data and the facilitation of high-precision processing. Laser processing can be applied to diverse range of materials.

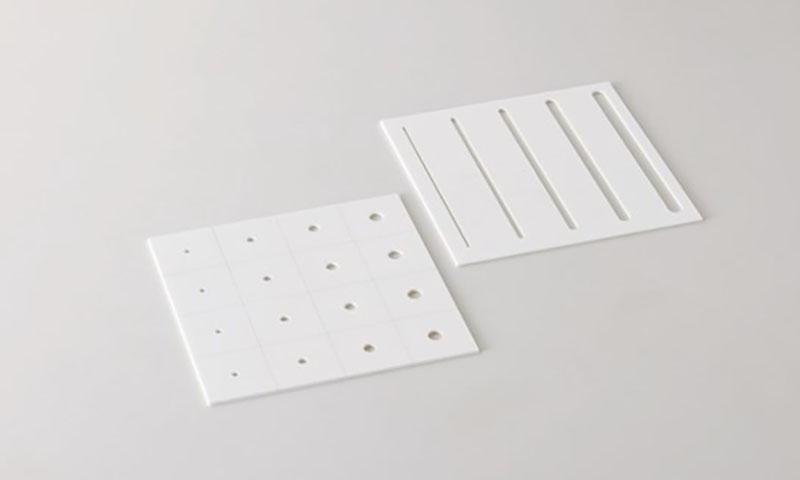

*The image shows an example of processing using a high-precision laser.

Features

- No mold required, allowing prototyping from small quantities

Since processing can be done by providing CAD data, this facilitates both mold cost and production lead time reduction. - Wide range of materials

We support laser processing for various ceramic materials, allowing you to choose the optimal material with suitable properties for your application. - High dimensional accuracy

Our technology supports post-sintering processing, so it is less susceptible to variations caused by shrinkage during sintering, allowing for high-precision finishes.

Material Data Comparison

| Material Material Code |

Alumina | Black Alumina | ||||||

|---|---|---|---|---|---|---|---|---|

| AO476T | AO477A | AO478D | AO493O | A1534 | ||||

| Alumina Content | 96% | 97% | 99% | 99.6% | - | |||

| Color | White | White | White | White | Black | |||

| Specific Gravity | 3.78 | 3.79 | 3.91 | 3.86 | 3.84 | |||

| Mechanical Characteristics | Vickers Hardness | GPa | 13.9 | 14.6 | 15.5 | 16.0 | 13.1 | |

| Flexural Strength 3 P.B. | MPa | 380 | 480 | 468 | 550 | 452 | ||

| Young’s Modulus | GPa | 340 | 370 | 396 | 390 | 312 | ||

| Thermal Characteristics | Thermal Conductivity | W/ (m・K) | 26 | 26 | 30 | 26 | 13 | |

| Coefficient of Linear Thermal Expansion 40-400℃ |

×10-6/K | 7.0 | 7.0 | 6.8 | 7.2 | 6.9 | ||

| Electrical Characteristics | Dielectric Strength | kV/mm | 15 | 16 | 23 | 15 | 30.2 | |

| Volume Resistivity | Ω・m | >1012 | >1012 | >1012 | >1012 | >1011 | ||

| Dielectric Loss Angle (1MHz) |

- | 3.0×10-4 | 2.0×10-4 | 1.0×10-4 | 3.0×10-4 | 36×10-4 | ||

| Dielectric Constant (1MHz) |

- | 9.6 | 9.1 | - | 9.6 | 10.3 | ||

| Features | MAX2.70T | High Strength | - | Ra0.08μm MAX |

Free of Co & Cr - Black Color - Low-Reflection Material |

|||

| Applications | Thick Film Applications - HIC |

Power Module |

Heat Dissipation Substrate | Thin Film Applications | - | |||

| Material Material Code |

Alumina-Zirconia | Forsterite | Silicon Nitride | Aluminum Nitride | ||||

|---|---|---|---|---|---|---|---|---|

| AZ214T | AZ211T | F1332B | SN240O | AN3130 | ||||

| Color | White | White | Ivory | Black | Gray | |||

| Specific Gravity | 3.75 | 4.01 | 3.10 | 3.30 | 4.30 | |||

| Mechanical Characteristics | Vickers Hardness | GPa | 12.3 | - | - | 14.0 | - | |

| Flexural Strength 3 P.B. | MPa | 450 | 650 | 150 | 1020 | 350 | ||

| Young’s Modulus | GPa | - | 360 | - | 300 | - | ||

| Thermal Characteristics | Thermal Conductivity | W/ (m・K) | 19 | 24 | 6 | 27 | 170 | |

| Coefficient of Linear Thermal Expansion 40-400℃ |

×10-6/K | - | 7.0 | - | 2.8 | 4.8 | ||

| Electrical Characteristics | Dielectric Strength | kV/mm | 22.6 | 16 | 23 | 13 | 15 | |

| Volume Resistivity | Ω・m | >1012 | >1012 | >1013 | >1014 | >1013 | ||

| Dielectric Loss Angle (1MHz) |

- | 2.0×10-4 | 2.7×10-4 | 0.3×10-4 | 19×10-4 | - | ||

| Dielectric Constant (1MHz) |

- | 9.6 | 10.8 | 6.7 | 9.6 | 8.8 | ||

| Features | High-Reflection Material | High Strength | Low Thermal Conductivity - Good Machinability |

High-Temperature Strength - Wear Resistance - Thermal Shock Resistance |

High Thermal Conductivity | |||

| Applications | - | Power Module |

Fuse | - | - | |||

*All values show in the above table are representative values based on in-house measurement results.

Design Guide

*Some products may not conform to the design guide.

Please consult us regarding laser scribe depth.

Processing Area

300×300(mm)

*Conditions differ for Alumina AO493O, Forsterite, Silicon Nitride, and Aluminum Nitride.

Please contact us for details.

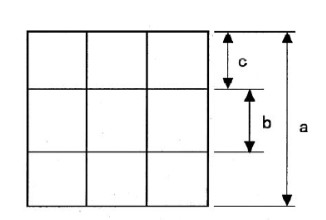

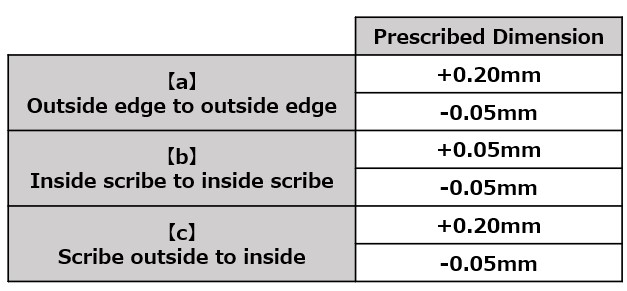

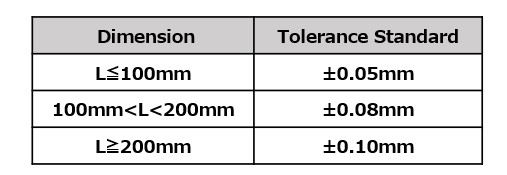

Dimensional Tolerance

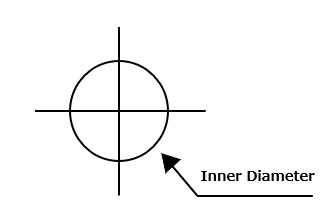

Hole Diameter

・Minimum Hole Diameter

If the plate thickness is 1.0mm or less, a diameter of 0.20mm is achievable (with a tolerance of ±0.05mm).

*We also undertake processing of even finer hole diameters and for plates thicker than 1.0mm. For example, we have experience processing holes of φ0.13mm in a plate thickness of 0.254mm.

・Hole Diameter Tolerance

For plate thicknesses up to 1.0mm, a tolerance of ±0.05mm applies regardless of the hole diameter.

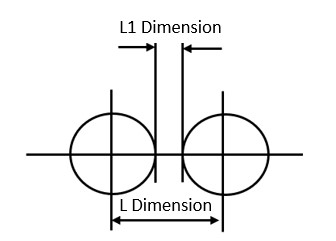

Hole Pitch

・Minimum Pitch Tolerance (L Dimension)

・Minimum distance between holes (L1 distance): Plate thickness < L1

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.