High-purity alumina (AO479U) is a material that achieves both low dielectric loss tangent (tan δ) and high strength, properties which are difficult to achieve at the same time for other materials.

It also has excellent heat resistance, chemical resistance, and plasma resistance.

Since this material has a low dielectric loss tangent, power loss can be reduced under high-frequency conditions. In addition, due to its high mechanical strength, there is minimal damage to parts due to heat generation and vacuum.

As a result, AO479U is used widely as a material for semiconductor processing equipment because it enables labor saving when tuning and overall stable operation of the manufacturing process.

Features

- Both low dielectric loss tangent and high strength

Despite its high purity, AO479U achieves both low dielectric loss tangent and high strength. - Supports a wide frequency range

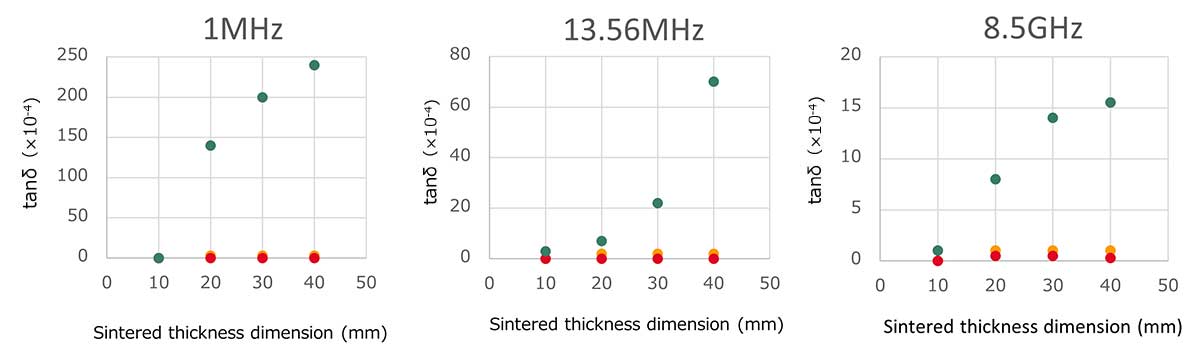

The dielectric loss tangent shows a low value in a wide frequency range from 1MHz to 8.5GHz. - Stable performance, even for thick products

Even products with a thickness of about 40mm, including the central part in the thickness direction, exhibit a stable low dielectric loss tangent value.

Processing Examples

Insulation parts for semiconductor processing equipment that uses radio frequencies

-

Base Plate

Φ400×20t (mm)

-

Insulator Ring

Φ400×50t (mm)

-

Chamber Components

Φ600×20t (mm)

*Above are processing examples. Sizes and shapes other than the above are also available. Learn how you can use AO479U for your manufacturing. Contact us for more details.

Property Data Comparison

Main characteristics comparison between Kyocera's low dielectric loss tangent, high strength, high purity alumina (AO479U), conventional low dielectric loss tangent alumina (AO479Q), and high purity alumina (AO479M)

| Material Material Code(New) Material Code(Old) |

Low Dielectric Loss Tangent, High Strength, and High Purity Alumina | Low Dielectric Loss Tangent Alumina | High Purity Alumina | ||||

|---|---|---|---|---|---|---|---|

| AO479U | AO479Q | AO479M | |||||

| A479U | A479Q | A479M | |||||

| Content (Al2O3) | % | 99.6 | 99.3 | 99.5 | |||

| Thermal Characteristics | Vickers Hardness HV9.807N | GPa | 15.2 | 15.7 | 15.7 | ||

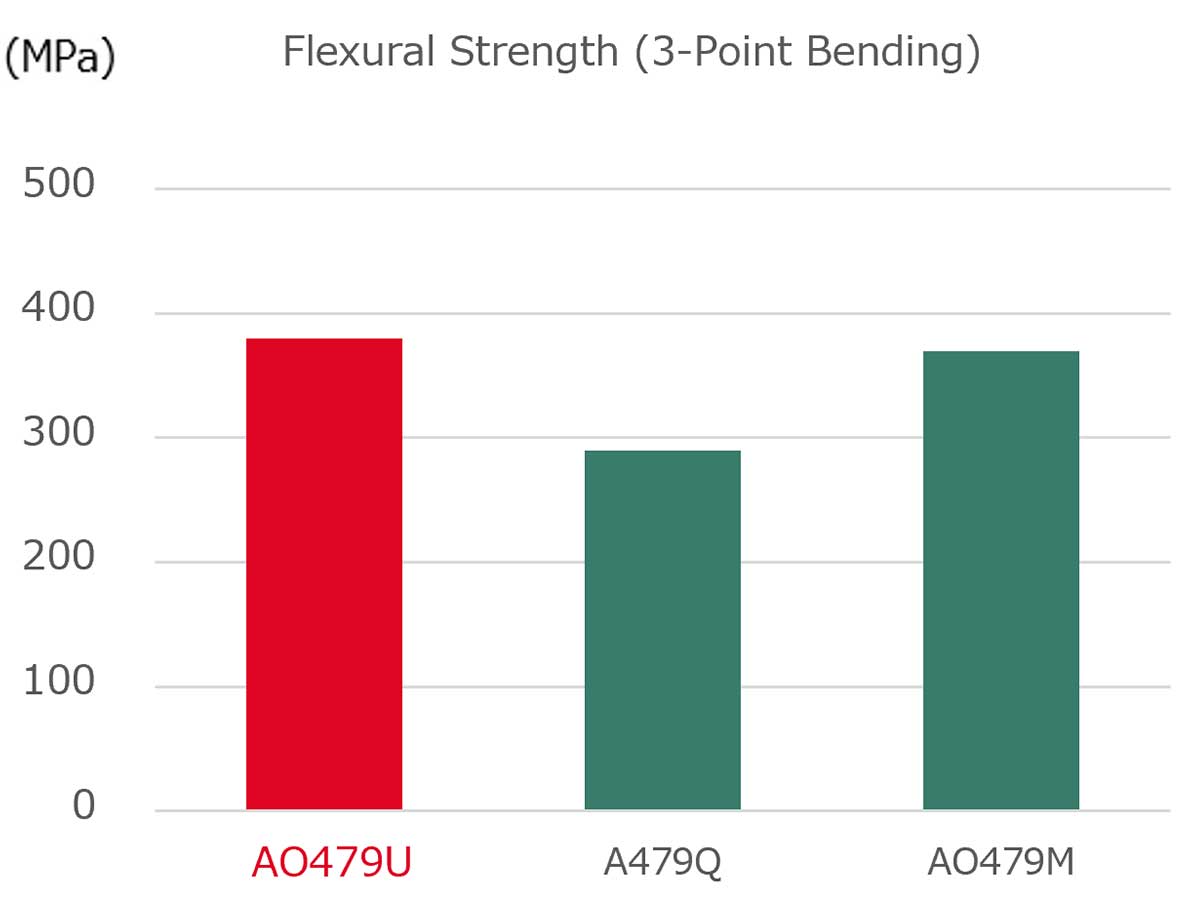

| Flexural Strength (3-Point Bending) | MPa | 380 | 290 | 370 | |||

| Young's Modulus | GPa | 387 | 377 | 370 | |||

| Thermal Characteristics | C.T.E. | 40~400℃ | × 10-6/K | 7.2 | 7.0 | 7.2 | |

| Thermal Conductivity | 20℃ | W/(m・K) | 32 | 30 | 32 | ||

| Electrical Characteristics | Surface Resistivity | 1MHz | × 10-4 | *See details of "Dielectric Loss Tangent (tanδ)" below. | |||

| 10-100MHz | |||||||

| 8.5GHz | |||||||

| Volume Resistivity | 20℃ | Ω・cm | > 1014 | > 1014 | > 1014 | ||

Measurement Data Details

Dielectric Loss Tangent (tanδ)

Kyocera's low dielectric loss tangent, high strength, high purity alumina (AO479U) exhibits low dielectric loss tangent values over a wide frequency range.

In addition, even a product with a thickness of about 40 mm exhibits a stable low dielectric loss tangent value, including at the central part of the product.

Dielectric loss tangent measurement by different frequencies, materials, and thicknesses

Measuring Method

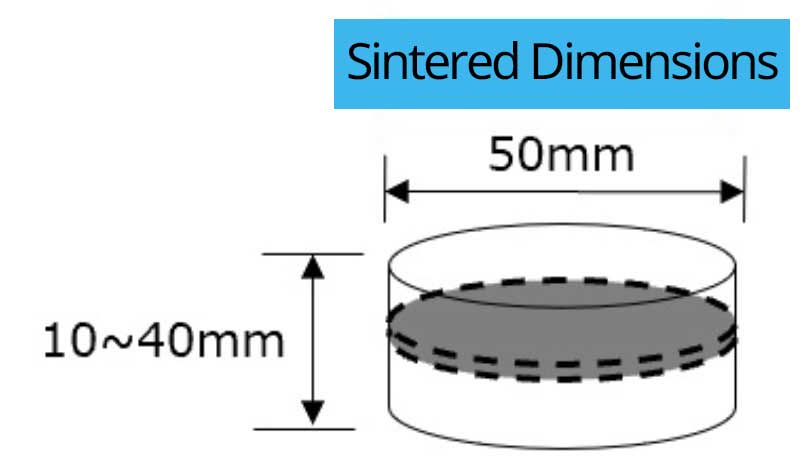

Prepared and measured test pieces sintered with thicknesses from 10 to 40 mm and cut out from the center with a thickness of 1 mm.

Measuring Device

| 1MHz: | C meter (bridge circuit method) |

| 13.56MHz: | Impedance analyzer (high-frequency current voltage method) |

| 8.5GHz: | Network analyzer (cavity resonator method) |

● AO479U (A479U)

● AO479Q (A479Q)

● AO479M (A479M)

High Strength

Kyocera's low dielectric loss tangent, high strength, and high purity alumina (AO479U) has a low dielectric loss tangent equivalent to that of conventional materials. It also has a higher strength than high purity alumina for mechanical applications (AO479M).

Interest in how to implement high-strength, low-dielectric-loss tangent materials for severe plasma environments that require heat resistance, chemical resistance, and plasma resistance, or are you interested in stable process operation by reducing power loss? Please feel free to contact us.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.