Features

- Available for Alumina- and Sapphire- integrated Complex Shaped Products

- Maintains Superior Ceramic Properties like heat resistance, chemical resistance and plasma resistance without adhesives

- Monolithic Structure ensures High Hermeticity and Mechanical Strength at the bonded boundary

Case 1

Transparent parts with Exceptional Resistance against Plasma and Chemicals

(Sapphire Monolithic Bonding)

The adhesive-free Sapphire monolithic bonding maintains superior sapphire properties such as plasma resistance, chemical resistance, heat resistance and mechanical strength even under a severe environment with plasma or exposed chemicals. In addition, it can be used where transparency is required, as the bonding boundary is not visible.

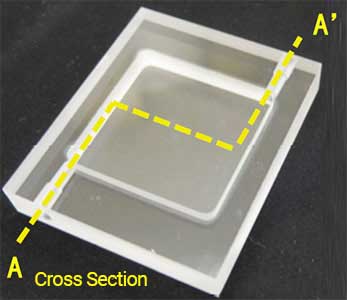

Design

Samples

-

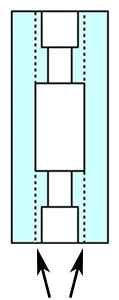

Plasma Generating Tube

(Size: Φ100mm)

(Size: Φ100mm)

-

Flow Cells

(Size: 30×25mm)

(Size: 30×25mm)

-

Side

-

A-A'

Bonding

Bonding

Area

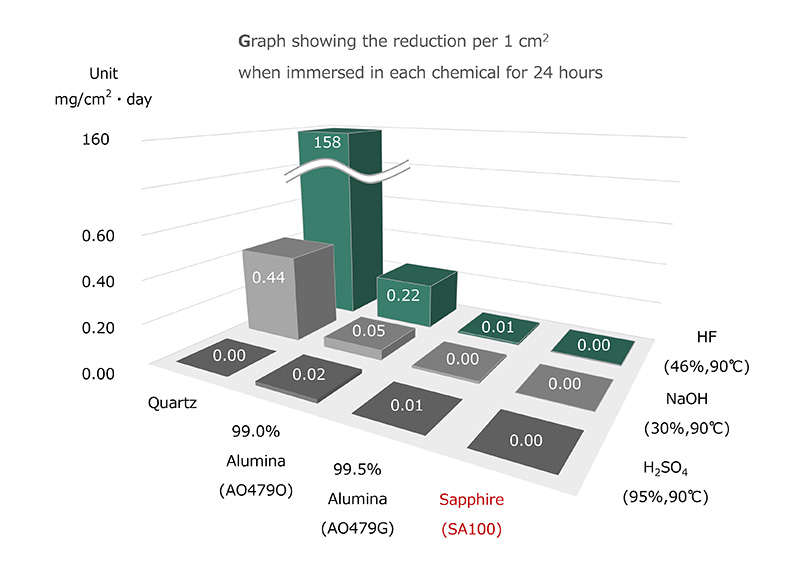

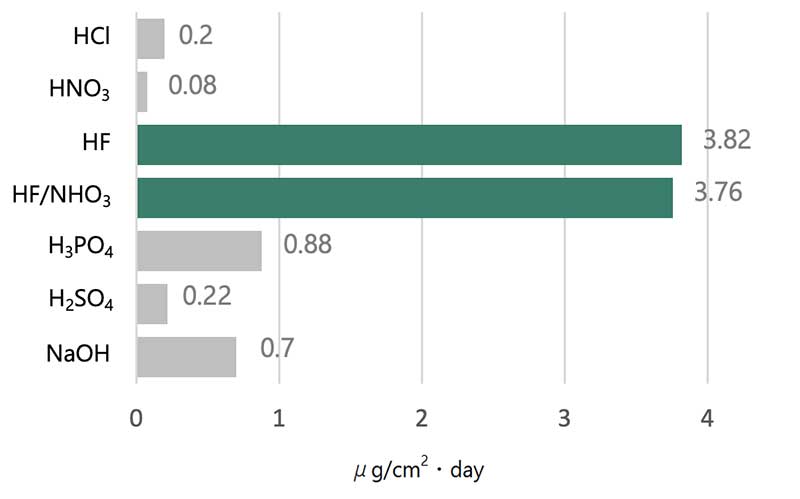

Chemical Resistance of Sapphire

Compared to Quartz and Alumina, Sapphire has superior chemical resistance.

Amount of reduction when immersed in each chemical

Measurement conditions

1 x 1 x 0.02 (inches)

Sapphire piece immersed for 6 days

| HCl | :35% 20℃ |

| HNO3 | :50% 20℃ |

| HF | :46% 60℃ |

| HF/HNO3 | :40/10% 60℃ |

| H3PO4 | :60% 100℃ |

| H2SO4 | :95% 95℃ |

| NaOH | :30% 100℃ |

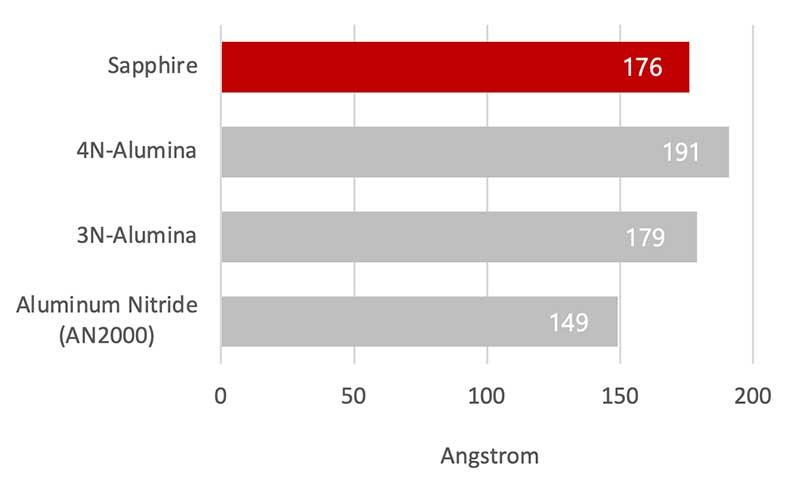

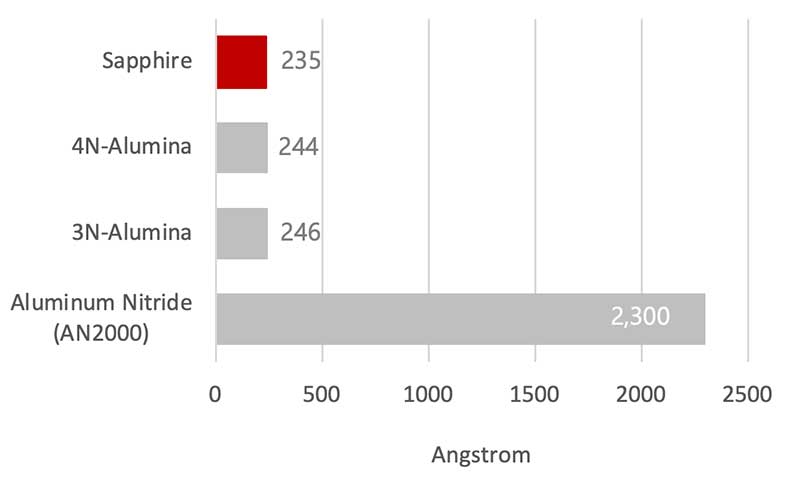

Plasma Resistance of Sapphire

High durability under both fluorine-based gas and chlorine-based gas plasma environment. *Measured on polished surfaces

Etching amount in fluorine-based gas (SF6) plasma environment

Measurement conditions

| Apparatus | Magnetron type RIE Equipment |

| Pressure | 25mTorr |

| Gas flow rate | 50sccm |

| RF output | 600W |

| Magnetic force | 150gauss |

| Vdc | 210V |

| Time | 1 hour |

Etching amount in chlorine-based gas (Cl2) plasma environment

Measurement conditions

| Apparatus | Magnetron type RIE Equipment |

| Pressure | 25mTorr |

| Gas flow rate | 50sccm |

| RF output | 600W |

| Magnetic force | 150gauss |

| Vdc | 270V |

| Time | 1 hour |

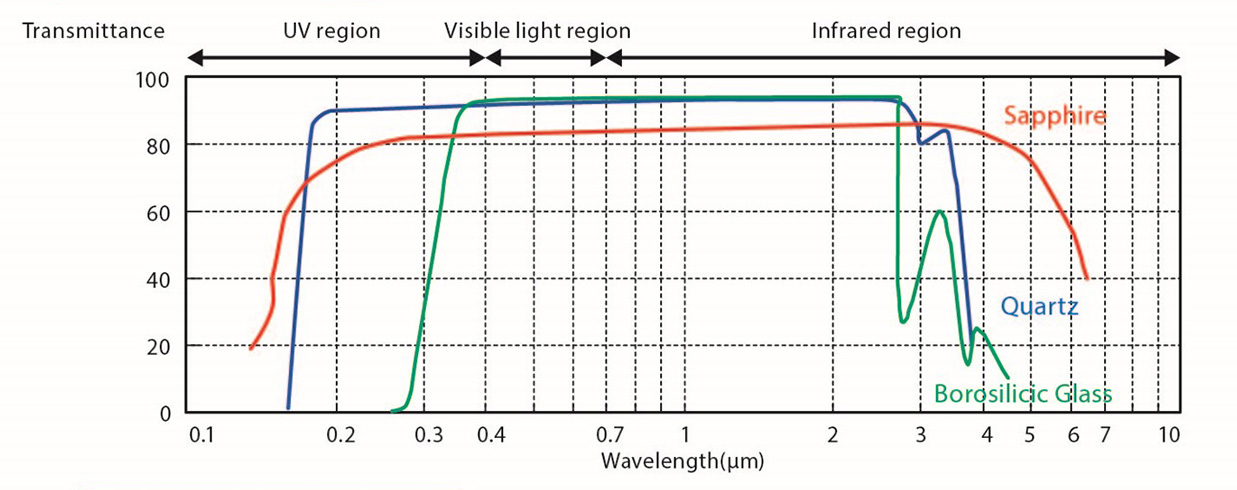

Light Transmission Characteristics of Sapphire

Sapphire has consistent transmittance over a wide wavelength range.

*The data are reference values and do not guarantee the characteristics of the product.

Case 2

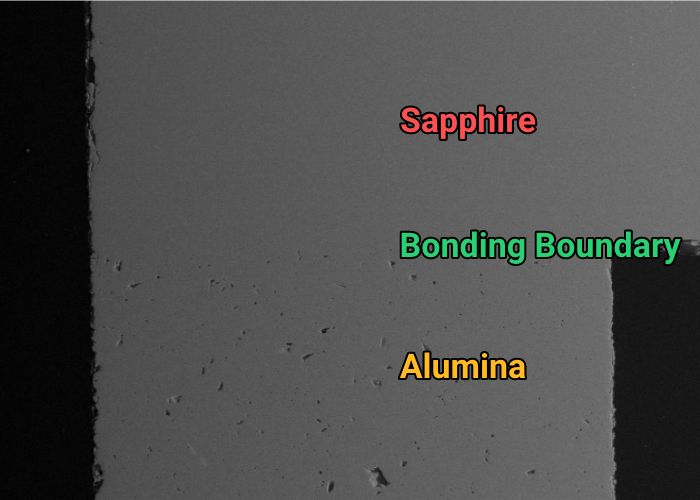

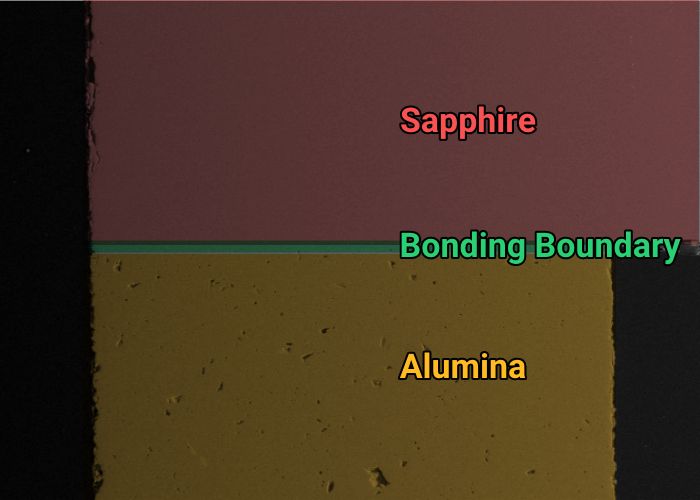

Sapphire and Alumina bonded bodies form highly hermetic seals

Sapphire and Alumina have high bonding strength and can be used where hermeticity is required. In addition, since no adhesive is used, the generation of impurities and particles is reduced around the bonded area. It is possible to use Sapphire and Alumina bonded parts, instead of all Sapphire parts, where transparency is required. Sapphire portion can be applied where transparency is required.

Bonded Body Sample

Measuring Window in Biochemical Analyzer

Hermeticity

- Achieve high vacuum requirement of 10-9 Pa・m3/s or less by helium leak test

- Ensure high hermeticity and mechanical strength by integrated bonding boundary

SEM Image

(×100)

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.