Achieving Mass Production of Small Ceramics with Complex Shapes

Leveraging Kyocera's extensive technical expertise in raw materials, die molding, and injection molding, we have achieved mass production of small ceramics with complex shapes that are difficult to manufacture using molding methods such as pressing, CIP, and extrusion.

Furthermore, by improving molding technology, we have enabled mass production of thin-walled parts which were previously difficult to manufacture.

Features

- Available for Stable Mass Production of High-Precision Ceramics (level of tolerance ± 0.01mm)

- Supports Requirements for Complex and Sophisticated Shapes, such as thin walls (thickness 0.02mm min.) and small diameters (0.08mm min. through holes)

- Customizable Using Kyocera’s Diverse Materials Lineup to Match Customer Required Characteristics.

*Numbers are reference values based on actual products and may vary depending on the required shape.

Design Samples

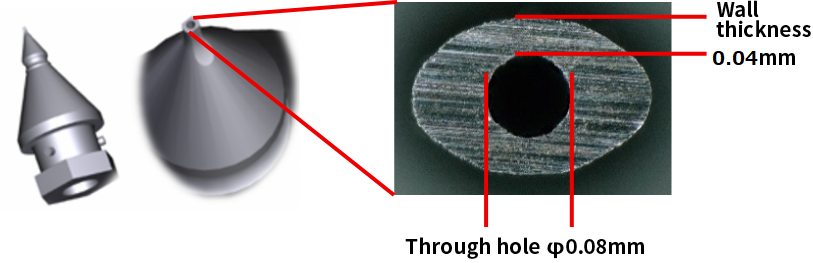

Case 1

Mass production of suction nozzles with 0.08mm diameter through holes (1,000 pieces/lot)

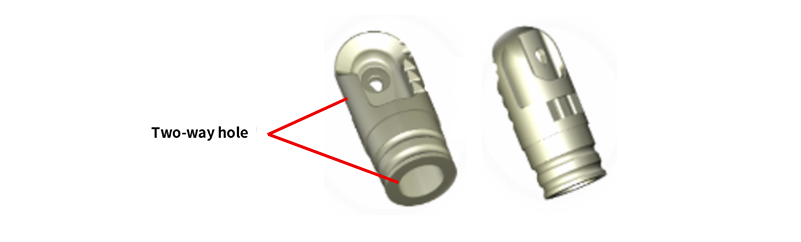

Case 2

Mass production of ultra-thin parts (0.02mm) and complex shape parts

Material Data Comparison

| Material Material Code |

Alumina | Zirconia | Colored Zirconia | |||

|---|---|---|---|---|---|---|

| AO480S | ZO201N | Z21N26 | ||||

| Color | - | Ivory | White | Black | ||

| Density | g/cm3 | 3.9 | 6.0 | 5.9 | ||

| Mechanical Characteristics | Vickers Hardness HV9.807N | GPa | 17.2 | 12.3 | 10.8 | |

| Flexural Strength (3-point Bending) | MPa | 480 | 1,000 | 980 | ||

| Fracture Toughness (SEPB) | MPa・m1/2 | 4.3 | 6 | 4 | ||

| Thermal Characteristics | Thermal Conductivity | 20℃ | W/(m・K) | 32 | 3 | 3 |

| Coefficient of Linear Thermal Expansion | × 10-6/K | 7.2 | 10.5 | 11.0 | ||

| Electrical Characteristics | Volume Resistivity | 20℃ | Ω・cm | >1014 | 1013 | 1013 |

| Features | - | Light Weight/High Stiffness | High Strength/High Toughness | |||

| Material Material Code |

High Toughness Zirconia | Semi-Conductive Zirconia | Silicon Nitride | |||

|---|---|---|---|---|---|---|

| ZA300O | Z21H12 | SN240O | ||||

| Color | - | Ivory | Black | Black | ||

| Density | g/cm3 | 5.5 | 5.7 | 3.3 | ||

| Mechanical Characteristics | Vickers Hardness HV9.807N | GPa | 10.0 | 12.4 | 14.0 | |

| Flexural Strength (3-point Bending) | MPa | 1,000 | 1,000 | 1,020 | ||

| Fracture Toughness (SEPB) | MPa・m1/2 | 11 | 4.5 | 7 | ||

| Thermal Characteristics | Thermal Conductivity | 20℃ | W/(m・K) | 4.5 | 4 | 27 |

| Coefficient of Linear Thermal Expansion | × 10-6/K | 10.2 | 10.4 | 2.80 | ||

| Electrical Characteristics | Volume Resistivity | 20℃ | Ω・cm | 1012 | 106 | >1014 |

| Features | - | High Strength/High Toughness | High Strength/Semiconductive | Light Weight/High Stiffness/High Strength | ||

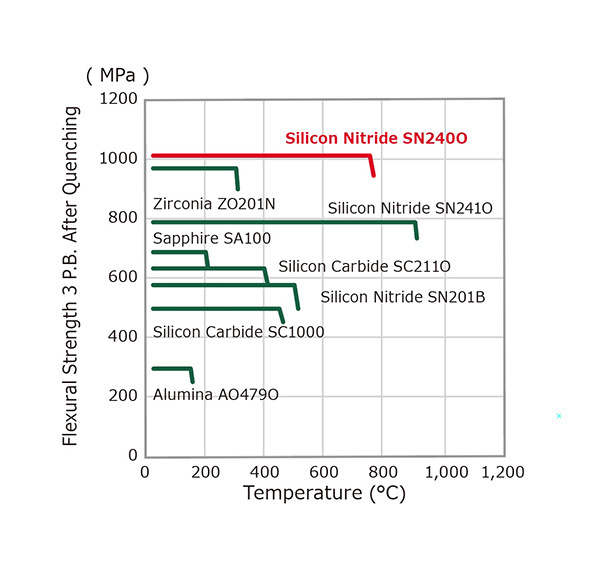

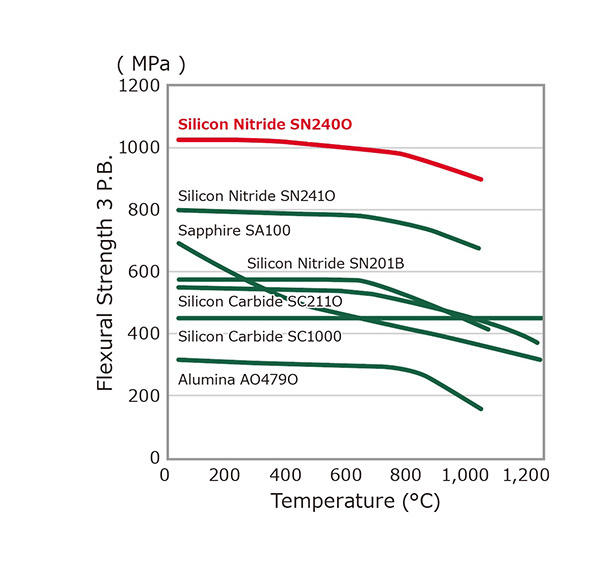

PICK UPSilicon Nitride SN240O

Silicon nitride (material code:SN240O) has superior thermal shock resistance and high-temperature strength in addition to excellent mechanical properties which typical engineering ceramic materials Alumina and Zirconia have. And SN240O has smaller specific gravity comparing to typical Alumina and Zirconia.

Thermal shock resistance

High-temperature strength

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.