Ceramic Materials

Alumina (Al2O3)

Widely used material with high electrical insulation and mechanical strength

Alumina was quickly adopted by the electronics field due to its high electrical insulation properties. In addition, because it has excellent corrosion resistance, wear resistance, and mechanical strength, it is used in many industrial machinery parts, and is the most widely used material among Fine Ceramics.

- Important property :

- Insulation

- Wear Resistance

Features

-

Well-balanced materialIt has been used for decades in electrical components for its high electrical insulation, and is widely used in mechanical parts for its high strength, and corrosion- and wear-resistance.

-

Well-known fine ceramic material for chemical and physical stabilityThermal properties: High heat resistance and high thermal conductivity

Mechanical properties: High strength and high hardness.

Other properties: High electrical insulation, high corrosion resistance and biocompatibility.

Shape

Dimensional precision achieved by machining

When dimensional precision is required for machined ceramics, Kyocera is capable of achieving the tolerances as shown in the table below. If greater tolerances are required, please consult us.

MACHINING DIMENSIONAL PRECISION

(Data are in mm unless otherwise specified)

1.Ground ceramic blocks and plates

2.Round and Square Bars

PRECISION MACHINED PRODUCTS

Ultra-precision is possible with Kyocera's unique techniques. Precision machining is affected by shape and material. Some practical examples are shown in the table below.

* Surface roughness depends on the material. The data shown hear indicates where alumina is used.

Property

Product examples

-

Pressure Sensor ComponentsKyocera's high-precision ceramic technology supports sensors for a wide range of pressure conditions.

- Heat Resistance

- Insulation Property

-

Substrates for Power ModulesHigh-strength substrates compatible with the direct bonding of copper sheets are suitable for a wide range of power module applications.

Substrates for Power ModulesHigh-strength substrates compatible with the direct bonding of copper sheets are suitable for a wide range of power module applications.- High Strength

- Low Thermal Expansion

-

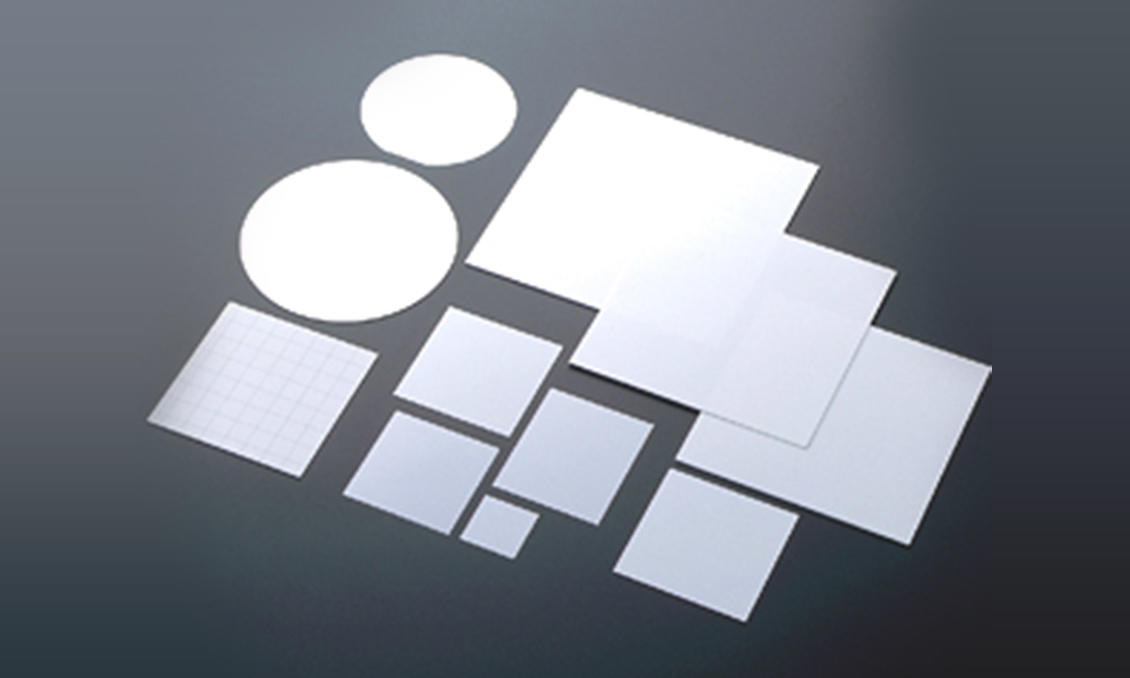

Thick Film SubstratesKyocera's thick film substrates correspond to the increased density and precision of thick film circuits.

Thick Film SubstratesKyocera's thick film substrates correspond to the increased density and precision of thick film circuits.- Large Sizes Available

- Thick Film Reliability

-

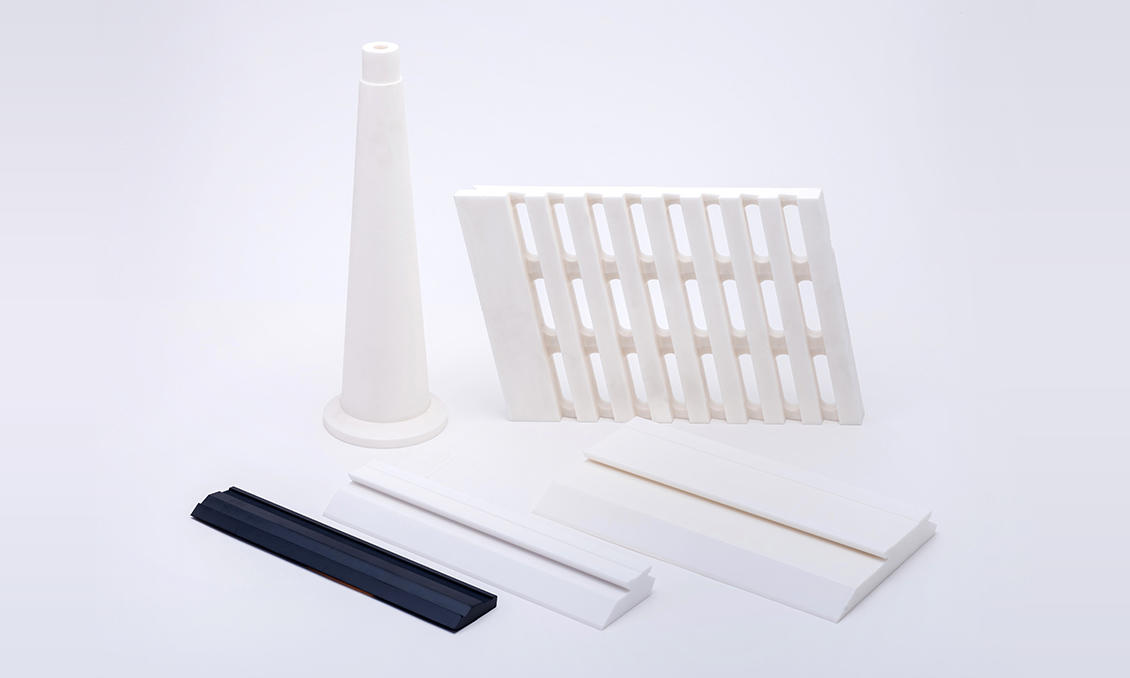

Pressed and Extruded PartsOptimum material selection and forming technology contribute to the improved performance of electronic devices.

Pressed and Extruded PartsOptimum material selection and forming technology contribute to the improved performance of electronic devices.- Wide Variety of Materials

- Various Shaping/Forming Technology

-

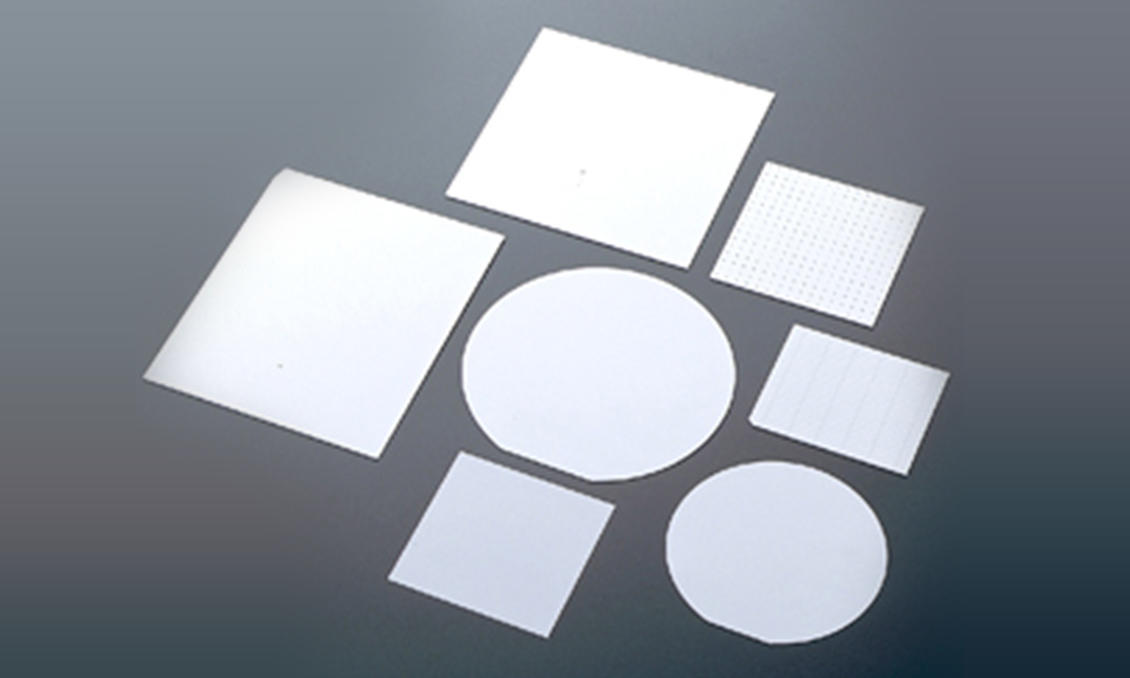

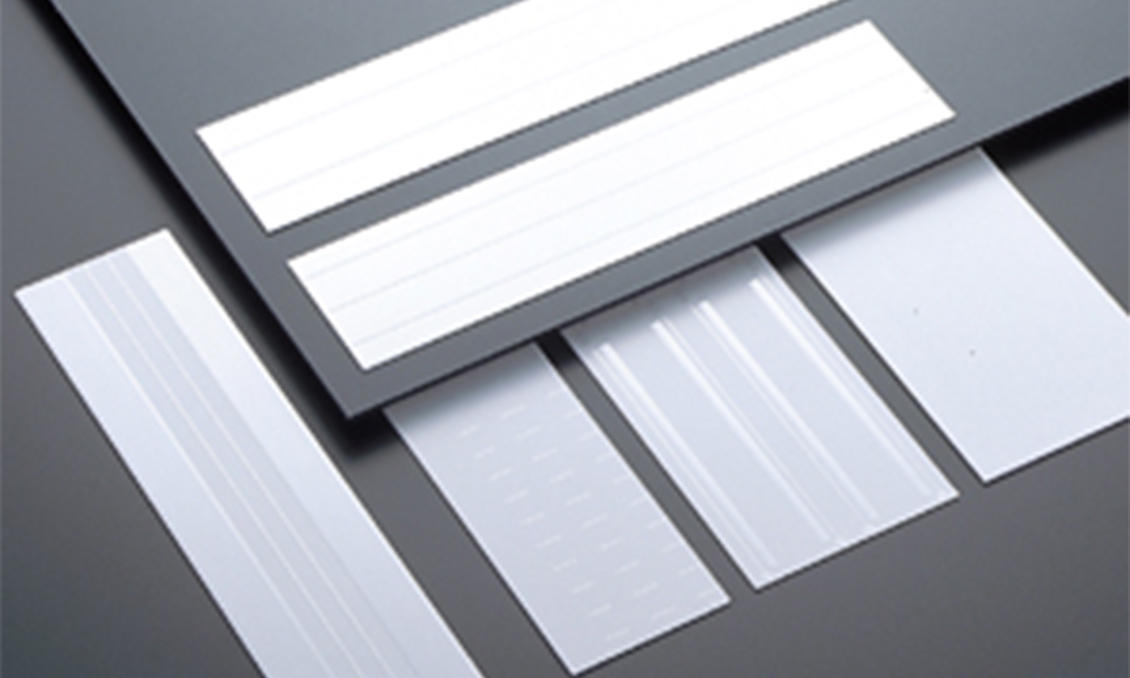

Thin Film SubstratesThin film substrates with superior surface smoothness.

Thin Film SubstratesThin film substrates with superior surface smoothness.- Excellent Surface Smoothness

-

Polished SubstratesPolished thin-film substrates with excellent surface smoothness, tight thickness tolerance and excellent flatness.

Polished SubstratesPolished thin-film substrates with excellent surface smoothness, tight thickness tolerance and excellent flatness.- Excellent Surface Smoothness

-

Glazed Substrates for Thermal PrintheadsGlazed substrates that are ideal for increasingly high-resolution printer heads.

Glazed Substrates for Thermal PrintheadsGlazed substrates that are ideal for increasingly high-resolution printer heads.- Fewer Surface Voids

- Surface Smoothness

-

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.- Design flexibility

- High-Temperature Durability

-

StatorsCeramic stators with superior chemical- and wear-resistant properties.

StatorsCeramic stators with superior chemical- and wear-resistant properties.- Wear Resistance

- Chemical Resistance

-

Cylinders & PistonsCeramic cylinders and pistons with superior chemical- and wear-resistant properties.

Cylinders & PistonsCeramic cylinders and pistons with superior chemical- and wear-resistant properties.- Wear Resistance

- Chemical Resistance

-

Sapphire Optical WindowsDirect bonding of sapphire and alumina without adhesives.

Sapphire Optical WindowsDirect bonding of sapphire and alumina without adhesives.- High-Temperature Durability

- Chemical Resistance

-

Decorative CeramicsAll-new decorative materials lend vibrant color and a luxurious feel to products.

Decorative CeramicsAll-new decorative materials lend vibrant color and a luxurious feel to products.- High Hardness

- Variety of color

-

Plastic Forming RollersForming rollers enhance product quality.

Plastic Forming RollersForming rollers enhance product quality.- Excellent Mechanical Properties

- High-Temperature Strength

-

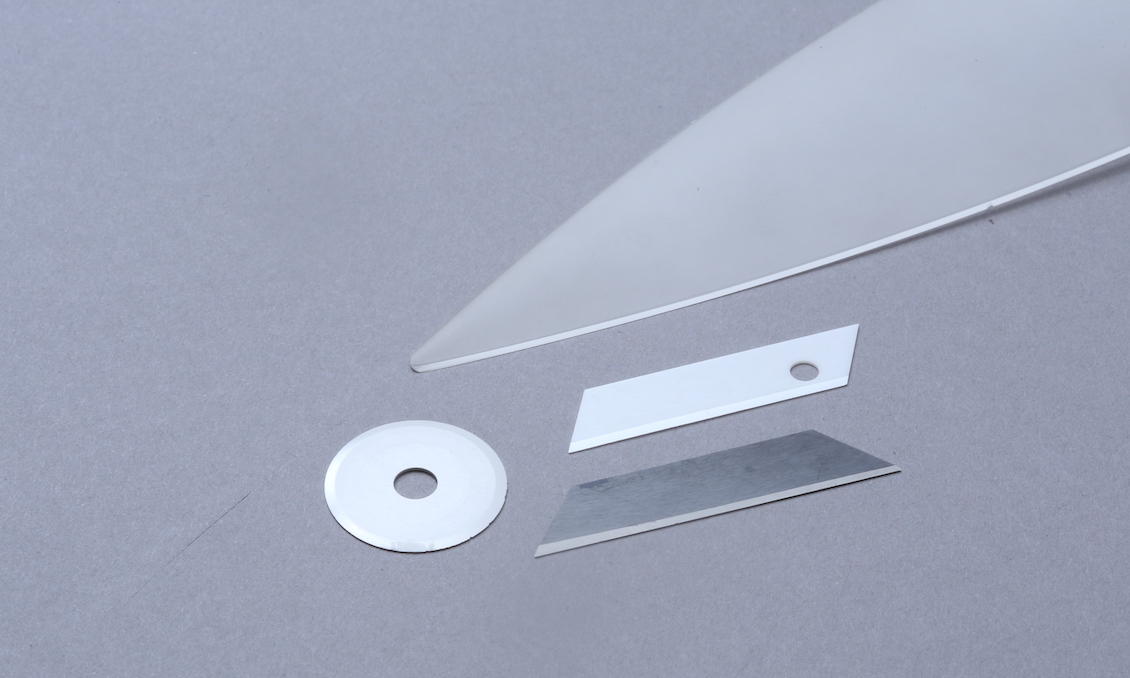

Cutters and Wear-Resistant Parts for Industrial MachineryKyocera's cutters are ideal for a variety of materials and high-precision machining technologies.

Cutters and Wear-Resistant Parts for Industrial MachineryKyocera's cutters are ideal for a variety of materials and high-precision machining technologies.- Wear Resistance

- Precision Machining

-

Papermaking Machinery PartsCeramic parts are effective for separating foreign materials and dewatering.

Papermaking Machinery PartsCeramic parts are effective for separating foreign materials and dewatering.- Wear Resistance

-

Textile Machinery PartsUsed in numerous textile machines due to its wear resistance and low friction.

- Wear Resistance

-

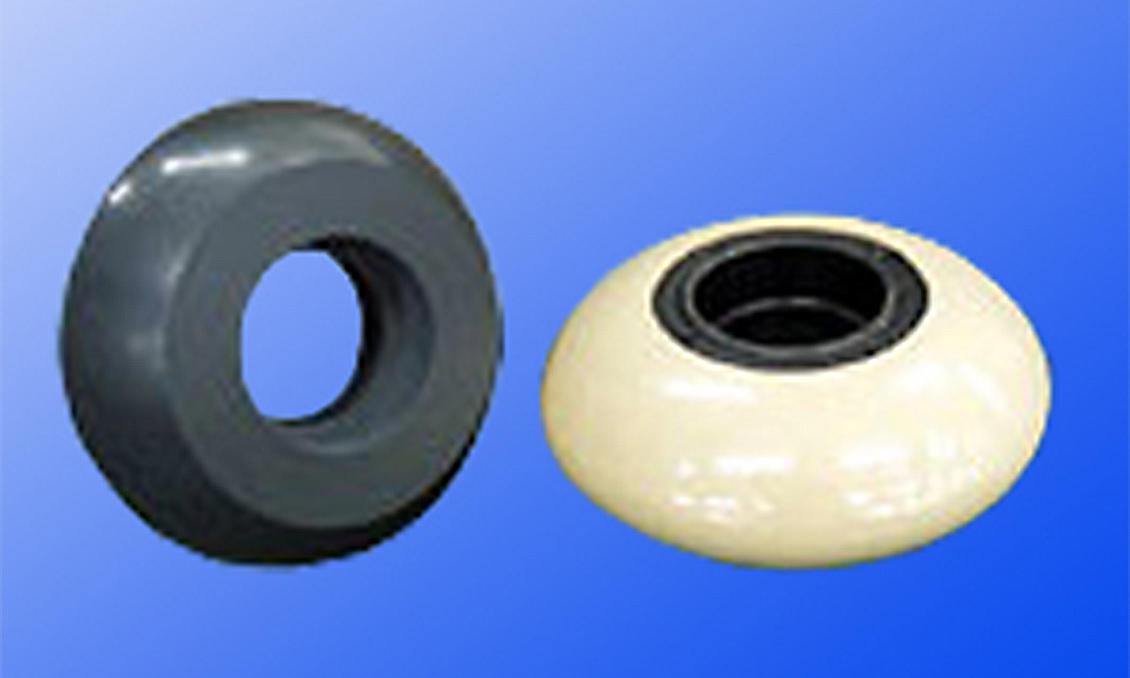

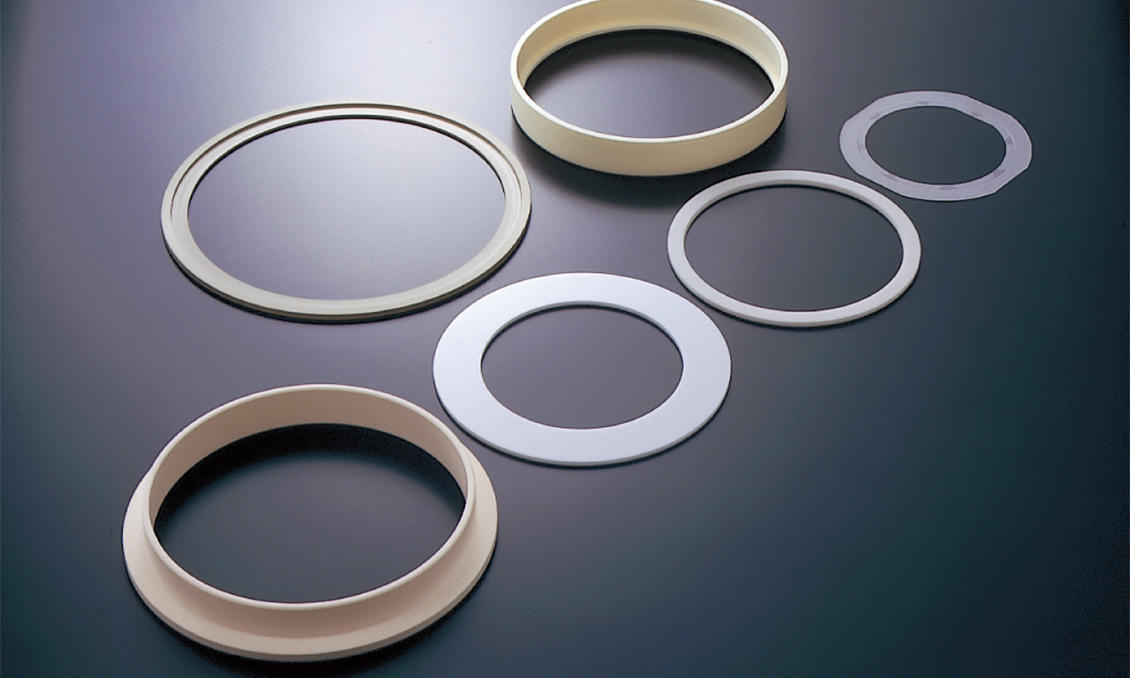

Faucets, ValvesCeramic faucet valves with superior wear resistance and sealing performance.

Faucets, ValvesCeramic faucet valves with superior wear resistance and sealing performance.- Wear Resistance

- Chemical Resistance

-

Electrical Insulators for FeedthroughsHighly biocompatible and reliable ceramic insulators.

Electrical Insulators for FeedthroughsHighly biocompatible and reliable ceramic insulators.- Insulation Property

-

Electrical Insulator PartsBiocompatible and able to be machined into intricate shapes and small forms.

Electrical Insulator PartsBiocompatible and able to be machined into intricate shapes and small forms.- Insulation Property

-

Metallized ComponentsHighly reliable metallized components for X-ray tubes and RF windows.

Metallized ComponentsHighly reliable metallized components for X-ray tubes and RF windows.- Hermeticity

- Bonding Technology

-

Metering ValvesCeramic metering valves with superior chemical- and wear-resistant properties.

Metering ValvesCeramic metering valves with superior chemical- and wear-resistant properties.- Wear Resistance

- Chemical Resistance

-

Ceramic SettersHigh-purity alumina setters are ideal for quality improvement and cost reduction.

Ceramic SettersHigh-purity alumina setters are ideal for quality improvement and cost reduction.- Heat Shock Resistance

- Corrosion Resistance

-

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.- Heat Resistance

-

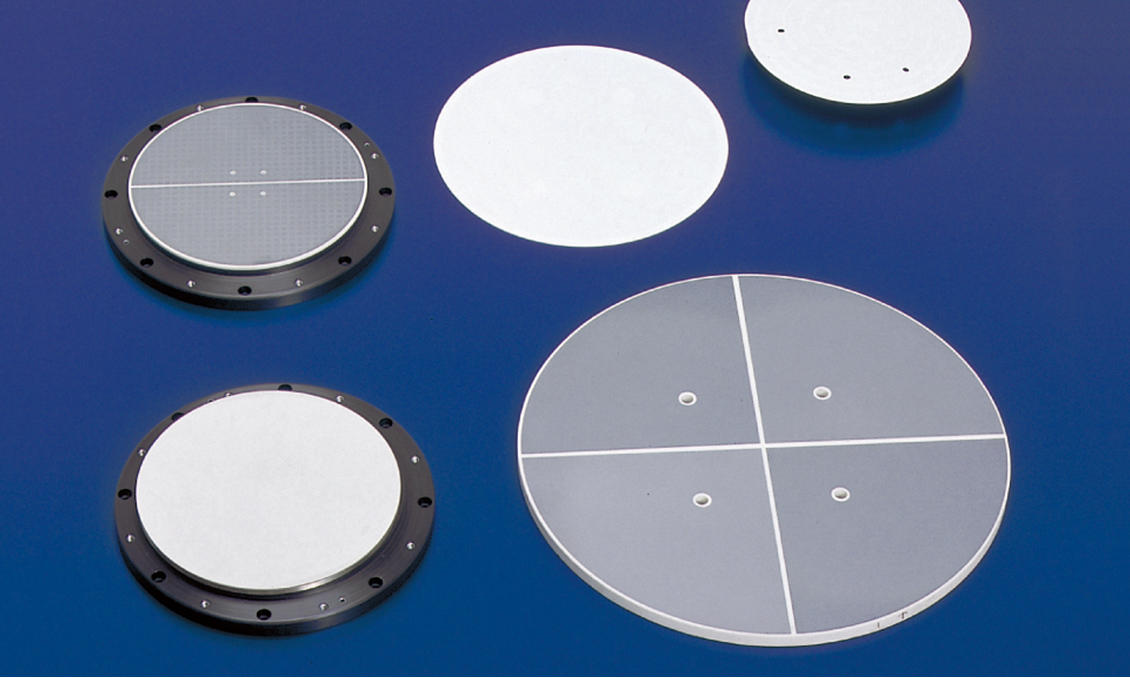

Electrostatic Chucks (ESCs)Highly plasma-resistant chucks perform well in a wide range of operating temperatures.

Electrostatic Chucks (ESCs)Highly plasma-resistant chucks perform well in a wide range of operating temperatures.- Plasma Resistance

-

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.- High Stiffness

- High-Precision

-

Domes, ChambersHigh-purity materials with high durability offer reliable plasma resistance.

Domes, ChambersHigh-purity materials with high durability offer reliable plasma resistance.- Uniform Electrical Properties

- Plasma Resistance

-

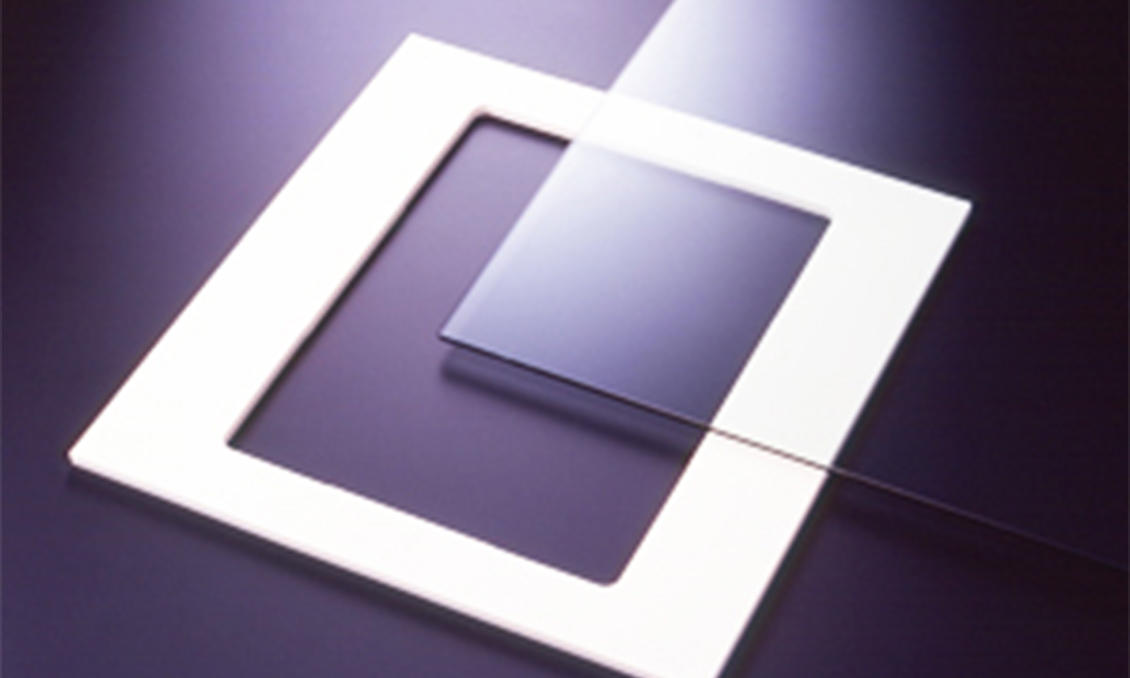

LCD Processing Equipment PartsRigid ceramic parts for liquid crystal display processing equipment.

LCD Processing Equipment PartsRigid ceramic parts for liquid crystal display processing equipment.- High Stiffness

- Low Reflection

-

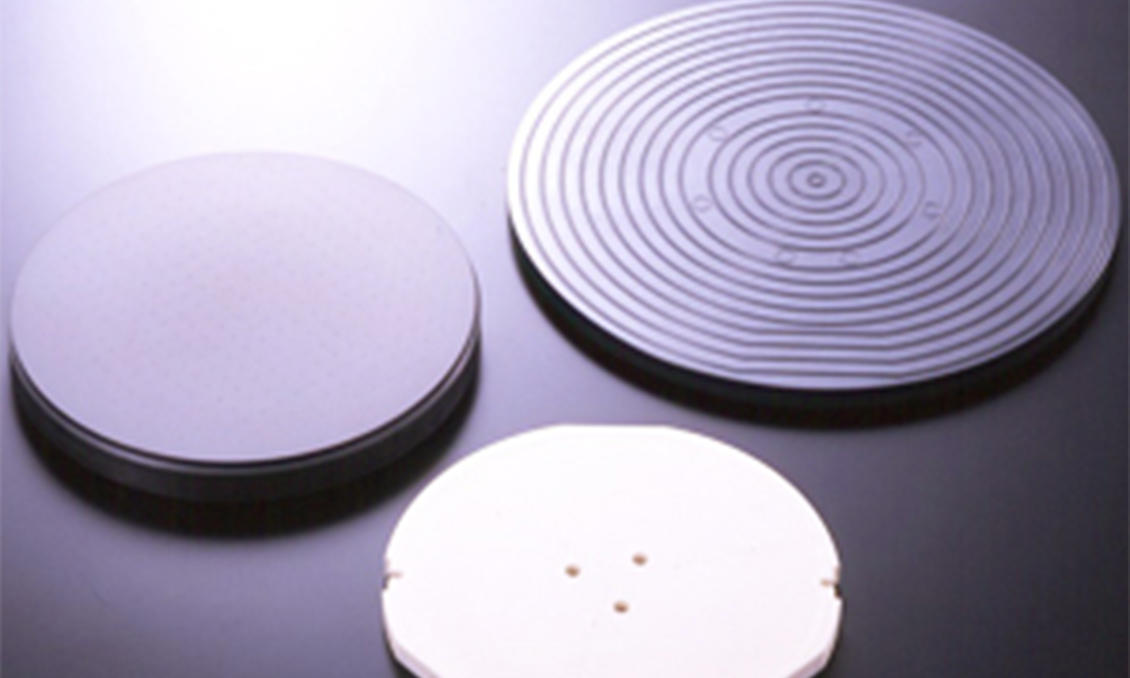

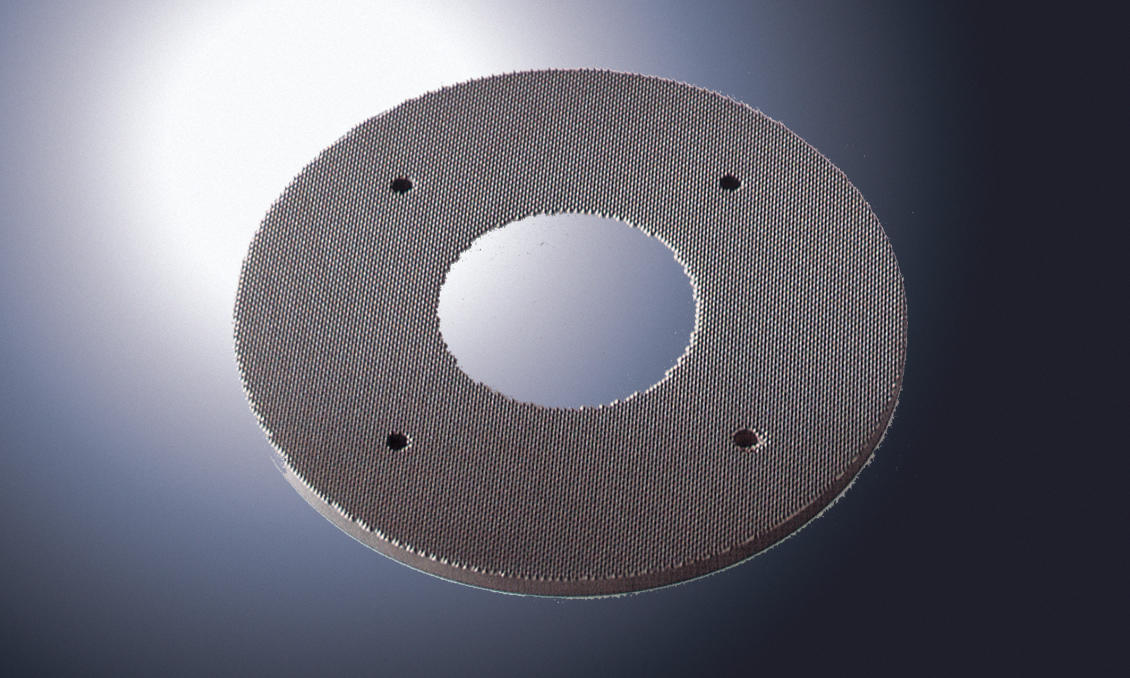

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.- Durability

-

Anti-Plasma MaterialsKyocera's plasma-resistant materials help create the next generation of etching technology.

Anti-Plasma MaterialsKyocera's plasma-resistant materials help create the next generation of etching technology.- Plasma Resistance

- Low Dielectric Loss

-

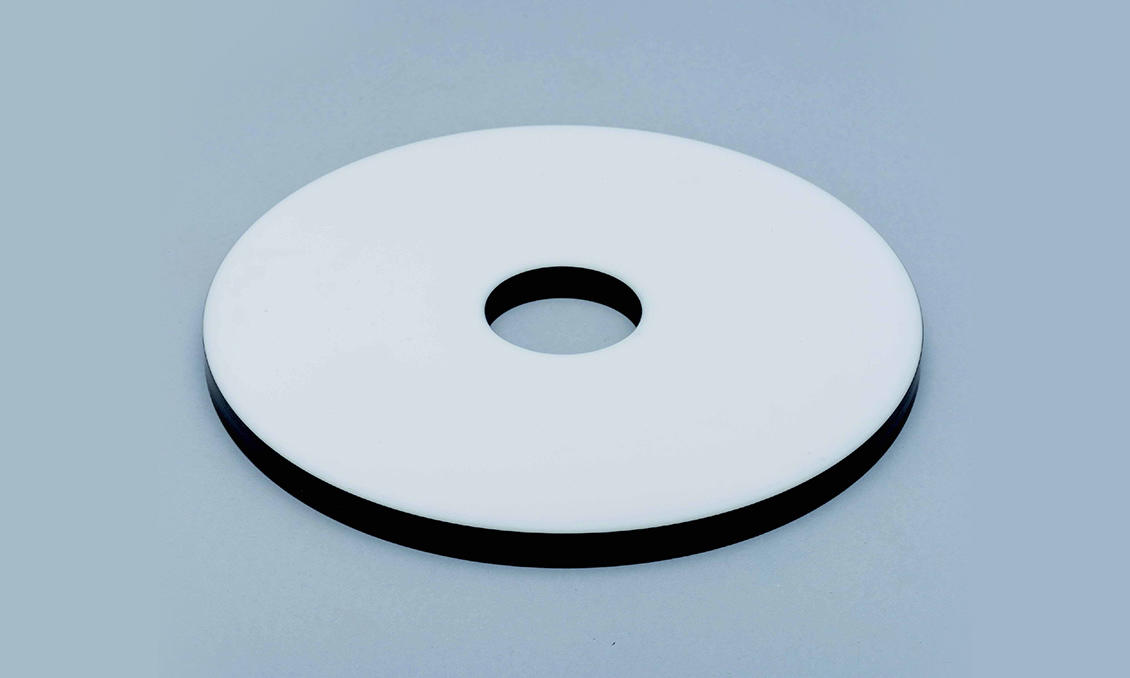

Polishing PlatesHigh-purity alumina ceramics are used for excellent rigidity and wear resistance.

Polishing PlatesHigh-purity alumina ceramics are used for excellent rigidity and wear resistance.- High Hardness

- Wear Resistance

-

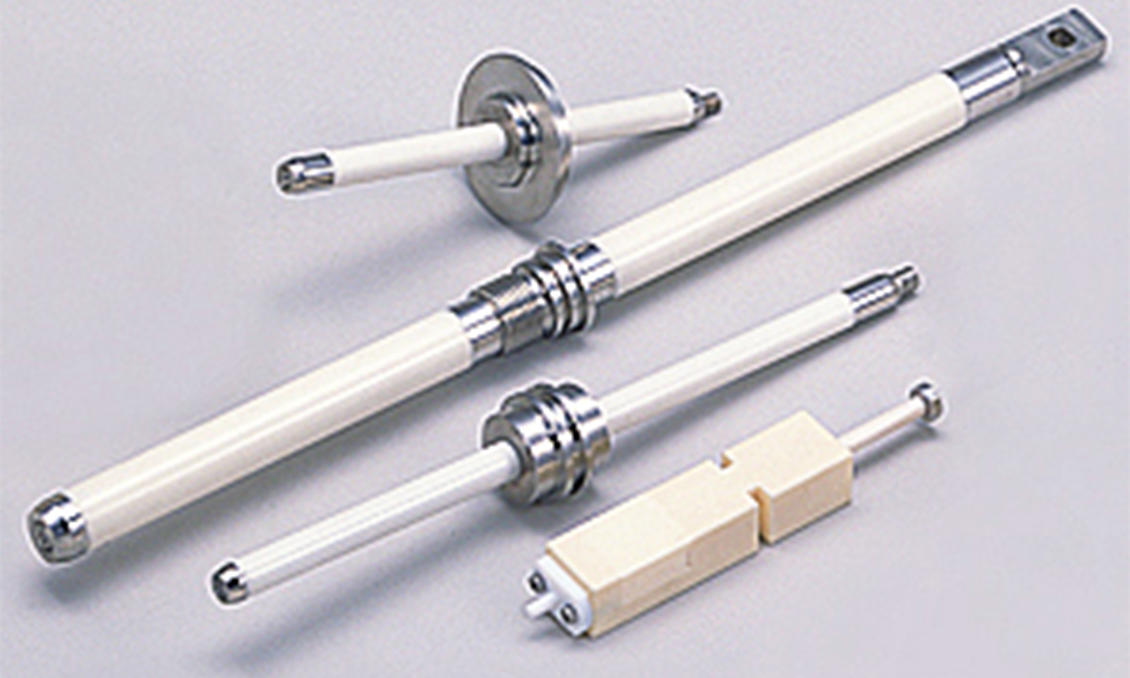

Feedthroughs (Multi-pin)Multi-pin terminal feedthroughs are based on advanced ceramic-to-metal bonding technology.

Feedthroughs (Multi-pin)Multi-pin terminal feedthroughs are based on advanced ceramic-to-metal bonding technology.- Airtightness

- Bonding Technology

-

Feedthroughs (Coaxial)Used in a wide range of applications, from radiation light sources and nuclear science to industrial equipment.

Feedthroughs (Coaxial)Used in a wide range of applications, from radiation light sources and nuclear science to industrial equipment.- Airtightness

- Bonding Technology

-

Isolator FlangesCeramic isolator flanges used in advanced experimental laboratories.

Isolator FlangesCeramic isolator flanges used in advanced experimental laboratories.- Airtightness

- Bonding Technology

-

FeedthroughsHighly reliable feedthroughs are proven components in a range of industrial sectors.

FeedthroughsHighly reliable feedthroughs are proven components in a range of industrial sectors.- Airtightness

- Bonding Technology

-

Ceramic ChambersHigh-performance ceramic chambers help control strong magnetic fields.

Ceramic ChambersHigh-performance ceramic chambers help control strong magnetic fields.- Airtightness

- Bonding Technology

-

Beam Position MonitorsHigh reliability proven by use in Japan's most well-known synchrotron radiation facility.

Beam Position MonitorsHigh reliability proven by use in Japan's most well-known synchrotron radiation facility.- Airtightness

- Bonding Technology

-

SiN (SN287) RF WindowsKyocera's technology enables non-oxide ceramic to be bonded with metals.

SiN (SN287) RF WindowsKyocera's technology enables non-oxide ceramic to be bonded with metals.- Airtightness

- Bonding Technology

-

Hermetic Subminiature D type Ceramic FeedthroughsSubminiature D type Ceramic Feedthroughs have good hermetic properties for Ultra High Vacuum Application.

Hermetic Subminiature D type Ceramic FeedthroughsSubminiature D type Ceramic Feedthroughs have good hermetic properties for Ultra High Vacuum Application.- Insulation Property

- Airtightness

-

Special Brazed FeedthroughsBrazed with aluminum or non-magnetic metals is available.

Special Brazed FeedthroughsBrazed with aluminum or non-magnetic metals is available.- High Thermal Conductivity

- Insulation Property

-

Vacuum Interrupter Ceramic TubeCeramic Insulator Tubes are used in vacuum interrupters for medium voltage switch gear (approx. 6kV to 80kV).

Vacuum Interrupter Ceramic TubeCeramic Insulator Tubes are used in vacuum interrupters for medium voltage switch gear (approx. 6kV to 80kV).- Insulation Property

- Airtightness

Ceramic Materials

- AluminaAl2O3

- Single-Crystal SapphireAl2O3

- ZirconiaZrO2

- Silicon NitrideSi3N4

- Silicon CarbideSiC

- Zirconia Toughened AluminaZTA

- Cordierite2MgO・2Al2O3・5SiO2

- CermetTiC,TiN

- YttriaY2O3

- Single-Crystal YAGY3Al5O12

- YAG-dispersed AluminaAl2O3

- Aluminum NitrideAlN

- Silicon-Infiltrated Silicon CarbideSiSiC

- Porous Ceramics

Customizable

We have a wide range of technologies such as material technology, process technology, design technology, measurement/evaluation technology, and integrated processes from materials to products in-house, so we can respond to various customizations. Please feel free to contact us first.