Excellent wear resistance, stable quality and long service lifeFine Ceramics for Textile Machinery

Catalog Overviews

Pick Up 01

Used in many textile machinery by taking advantage of its abrasion resistance and low friction coefficient

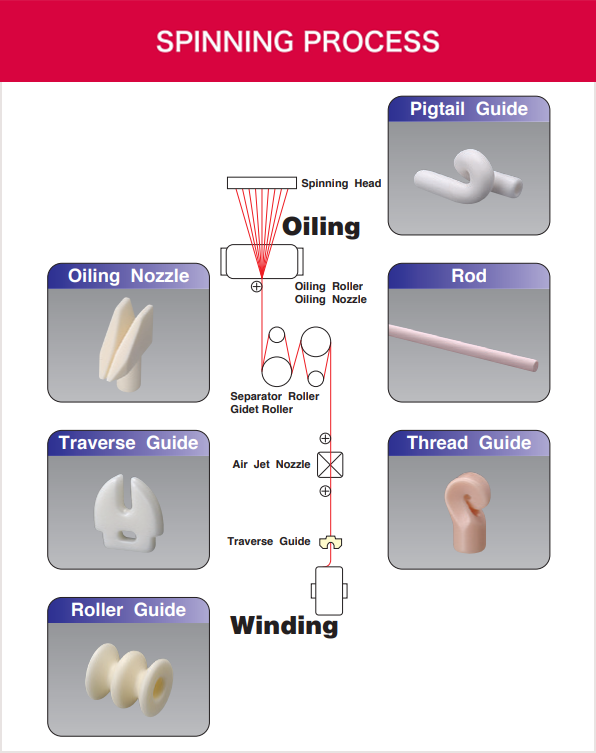

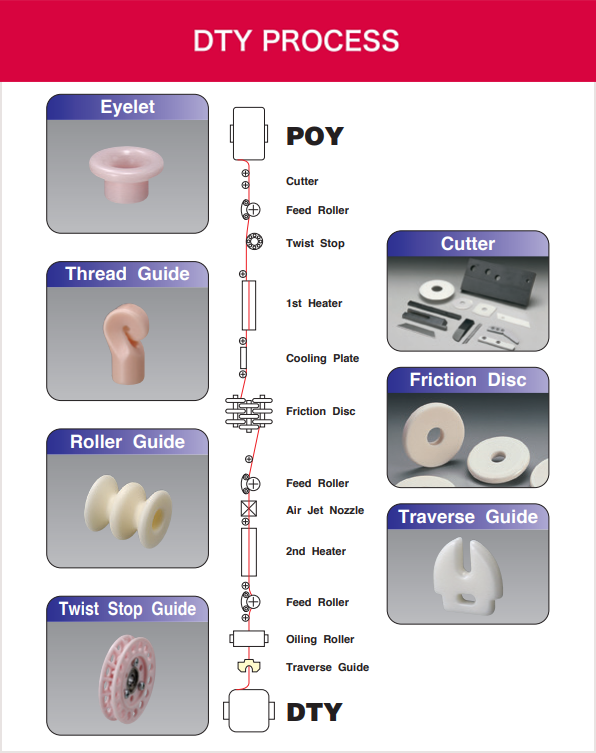

Ceramics are used in the guide parts of various textile machinery, yarn processing nozzles, oil supply nozzles, rollers, twisted yarn parts, etc. The smoothness and abrasion resistance of ceramics are utilized to reduce damage to high-speed threads. We propose optimum specifications for diversifying yarn types and multifunctional yarns (ultrafine fiber yarn and different shape yarn) from a wide variety of ceramic materials and surface finishes, and contribute to prolonging the life of equipment.

Pick Up 02

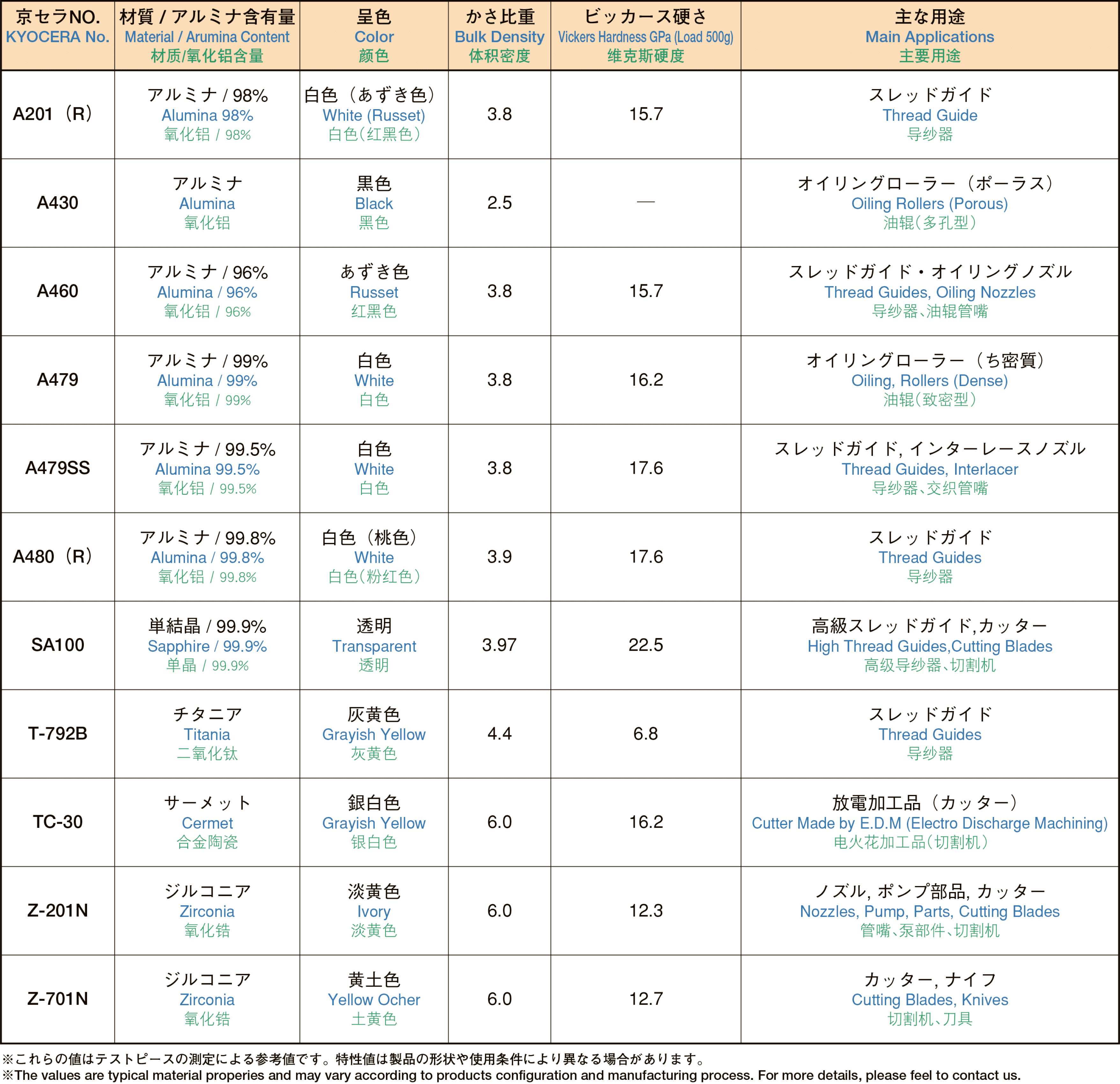

Main Materials and Applications of Ceramics for Textile Machinery

Pick Up 03

Example of parts for textile machinery

Index of Catalog

The catalog introduces the following material properties and product examples. Download the PDF to learn more.

-

Fine CeramicsEngineering Ceramics / Material Characteristics / Joining Ceramics to Other Material / Manufacturing Process

-

Material Characteristics of Thread GuideMaterial Characteristics Table / Surface Finish

-

R & D TechnologyDesign & Simulation Technology / Analysis Technology

-

Overview of the Textile Manufacturing Process[ SPINNING PROCESS ]

Chip Cutter / Oiling Nozzle / Traverse Guide

[ DTY PROCESS ]

Friction Disc

[ GENERAL PROCESS ]

Eyelet Guide / Roller Guide / Tail Guide / Hook Guide / Slit Guide / Rod