Longer life with less maintenance, leading to higher quality castingsAluminum Foundry & Casting

Catalog Overviews

Pick Up 01

Casting process parts that take full advantage of Kyocera's silicon nitride features

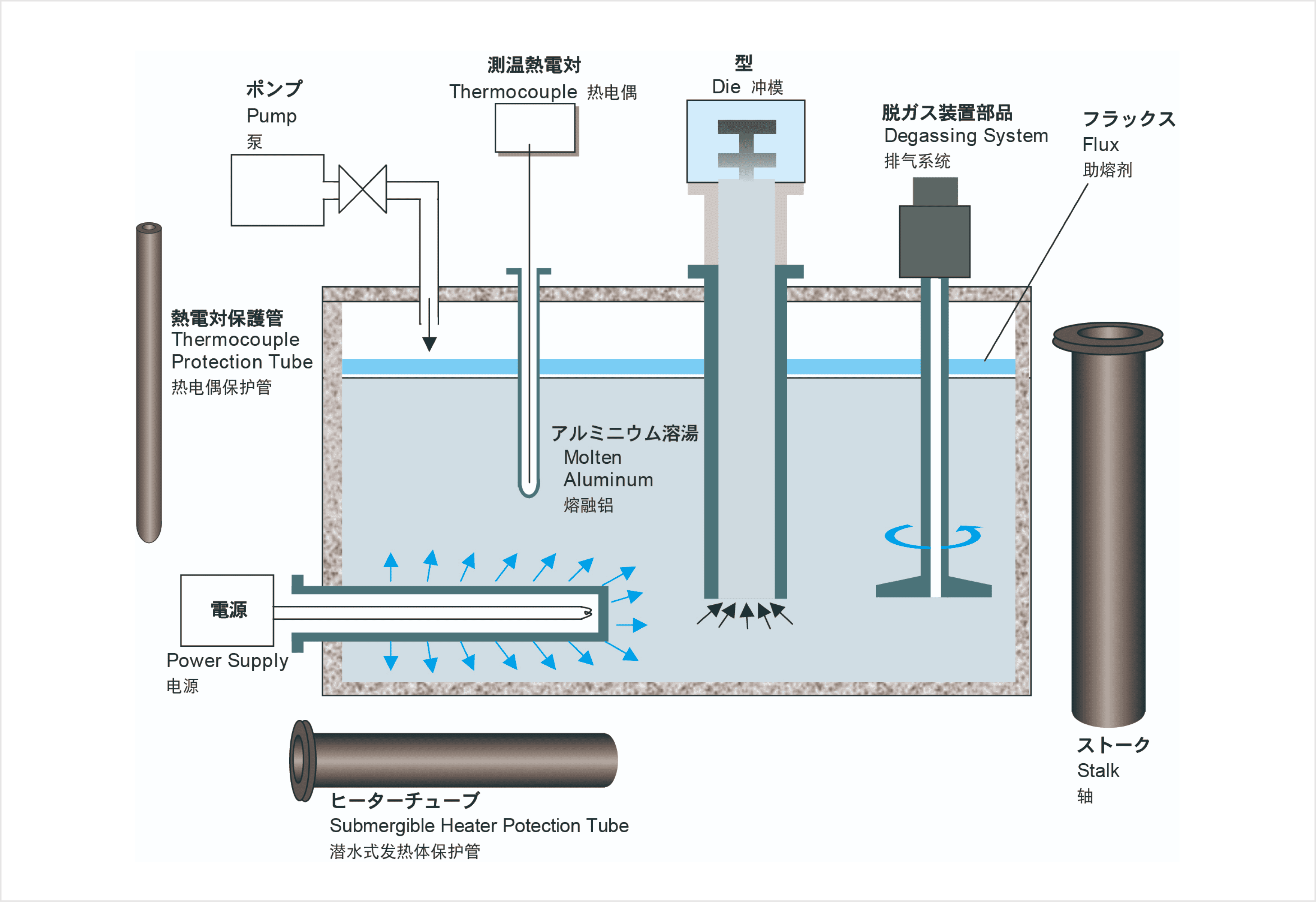

Ceramic parts are used in the manufacturing process for various metal parts, contributing to improved productivity by reducing the frequency of replacement and maintenance of equipment parts. Parts used in the casting process for molten metals at 700 °C or higher need high thermal shock resistance, high temperature strength, and high corrosion resistance. Silicon nitride is used for thermocouples, heater protection tubes, and casting stalk tubes. In addition, silicon nitride has low wettability with molten aluminum and is widely used in aluminum foundry. In steel manufacturing processes, it is used for molding of various steel materials, transfer rolls, bearings for plating baths, liners, and parts for caulking and drawing. In addition, sapphire is used for applications that require higher heat resistance and the prevention of impurities.

Pick Up 02

High-Reliability Ceramic Components Active in High-Temperature and High-Pressure Environments

Kyocera's fine ceramics have excellent properties such as strength, wear resistance and corrosion resistance, and are used in various fields including industrial machinery. Among them, silicon nitride has high strength and excellent thermal shock resistance, so it is used as a highly reliable component in high temperature and high pressure environments such as automotive parts.

Examples of Aluminum Foundry & Casting Parts

Pick Up 03

Six Features of Aluminum Foundry & Casting Parts

-

Maintenance-free and Ionger lifeSilicon nitride is unlike cast iron and old ceramics, inert against molten aluminum. So, it ensures longer life. For example, with minimum maintenance our silicon nitride stalk tubes have a record of being used for two to three years. Cleaning can be done on silicon nitride.

-

Contamination freeWhile iron contamination from the parts made of conventional material is quality concern, silicon nitride is different. It hardly reacts with molten aluminum and will help our customers to make high quality die casting parts.

-

Light weight and easy handlingSilicon nitride keeps its original strength up to 800°C. Its corrosion resistance and excellent strength characteristics permit a reIative thin wall thickness and it makes handling easy.

-

Less adhesion of molten metalBecause of covalent binding ceramics, silicon nitride has low wettability against molten metal and does not require coating.

-

Resistance to thermal shock and mechanical stressInitial preheating is required on virgin components. Once this has been performed, you can begin to realize better reliability than conventional ceramics. The high reliability is due to the mechanical strength and thermal shock resistance of silicon nitride.

-

Temperature stabilitySilicon nitride is an insulative materiaI. Therefore, It has low heat conduction. Its low specific heat allows minimum heat loss. This aides in more accurate temperature measurements for our thermocouple protection tube application, and facilitates molten metal transfer in our stalk tube applications. This advantage can reduce temperature of molten aluminum and overall energy costs.

Index of Catalog

The catalog introduces the following material properties and product examples. Download the PDF to learn more.

-

Fine Ceramics for Aluminum Foundry & CastingApplication / Advantages / Material Properties

-

Product ExamplesStalk (Feed Pipe) / Protection Tube for Thermocouple / Heater Protection Tube / Degassing Pipe and Roter / Fixtures for Wetting Process

-

Introduction of Fine CeramicsManufacturing Process / Engineering Ceramics