Discover & Learn

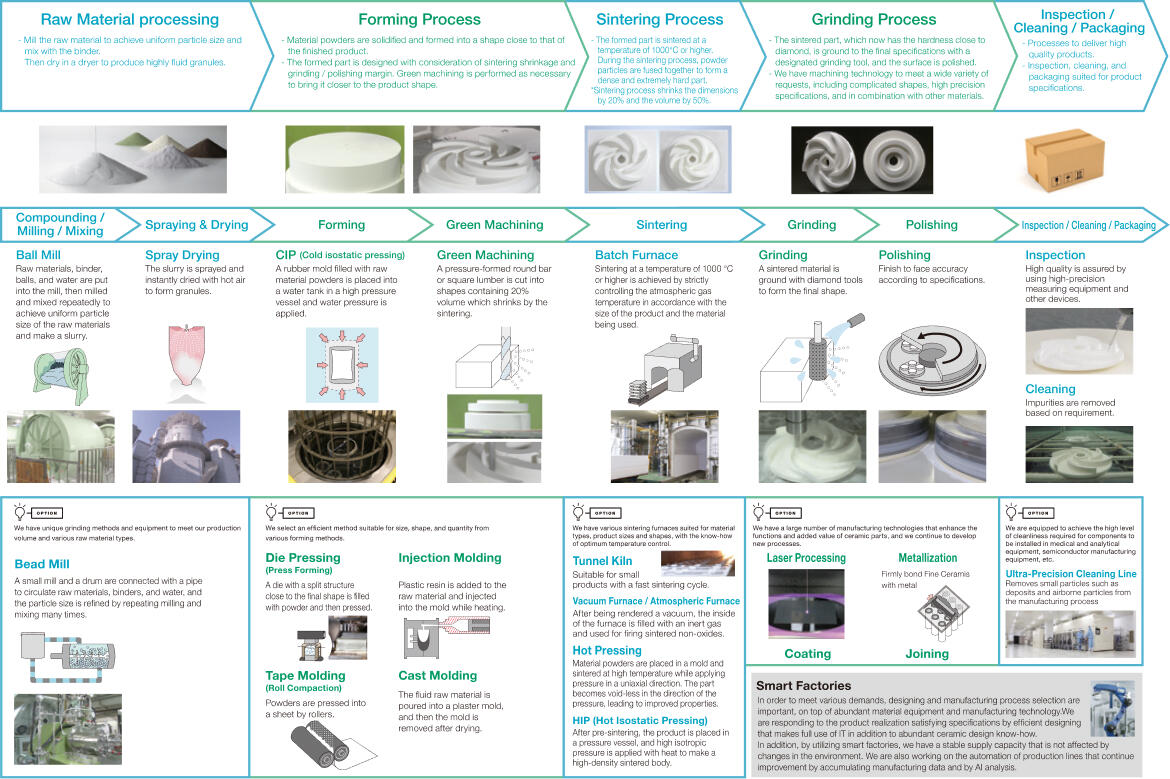

Manufacturing process of ceramics (polycrystalline)

The raw materials used in making Fine Ceramics (also known as "advanced ceramics") include inorganic solid powders with precisely controlled purity, particle size and distribution. These raw materials are formulated for specific properties and functionality, then mixed with a binding agent or binder. Afterward, they are shaped and cut to precise requirements and fired at extreme heat in temperature-controlled kilns. Firing removes the moisture and binders. With additional firing, powder particles are sintered together and the products shrink due to reduced porosity.

→To manufacturing process of single crystal sapphire