Design ideas for ceramic parts

Here we introduce typical points for making designs that take advantage of the features of Fine Ceramics.

1. Avoid mechanical impact

All ceramic materials can be brittle under impact. Please try to avoid designs that involve high energy, short duration stresses.

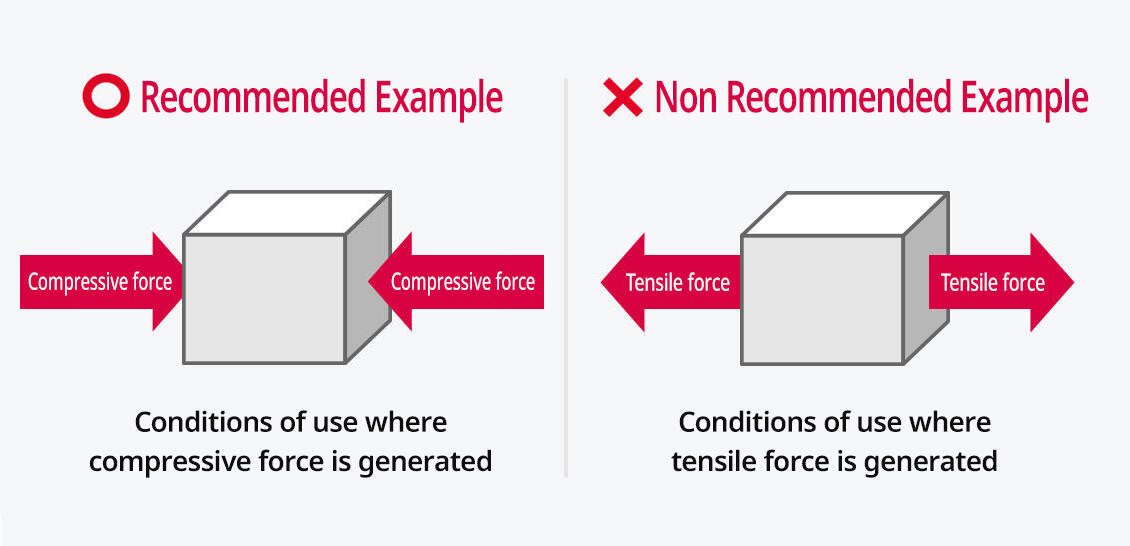

2. The stress should be compression, not tension

Fine Ceramics have high compressive strength but low tensile strength. Design so that the stress is in compression rather than tension.

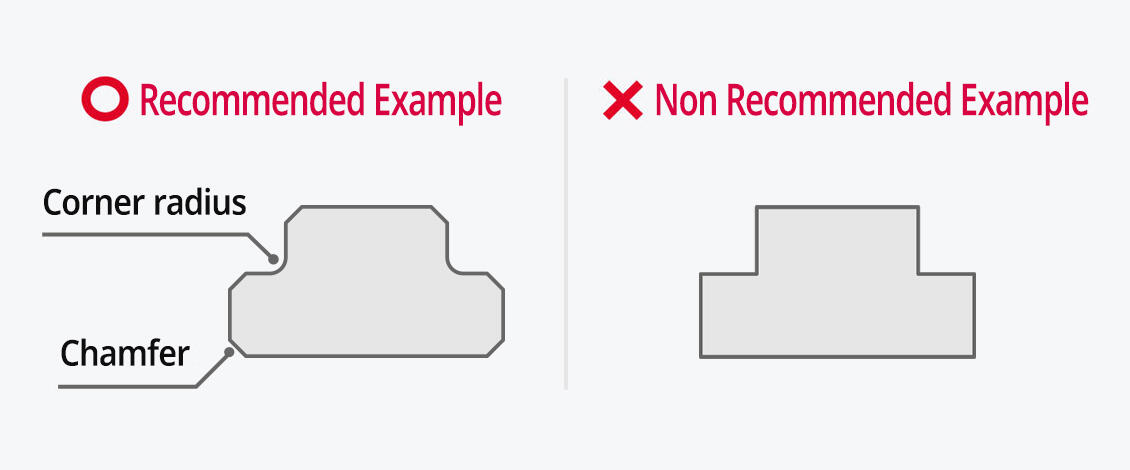

3. Avoid stress concentrations

Fine Ceramics cannot be plastically deformed, so they are vulnerable to stress concentration. Design to avoid stress concentration by chamfering or rounding the edges and corners, and avoiding protrusions and notches where possible.

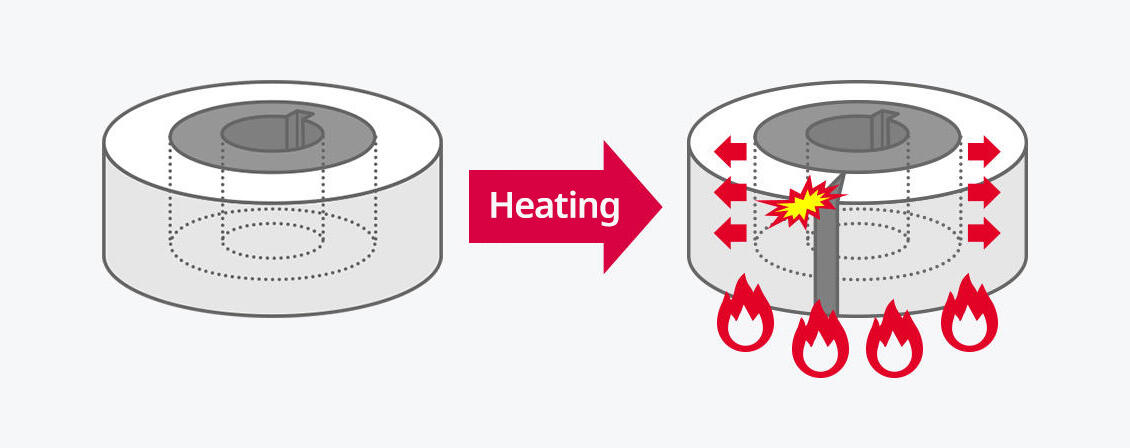

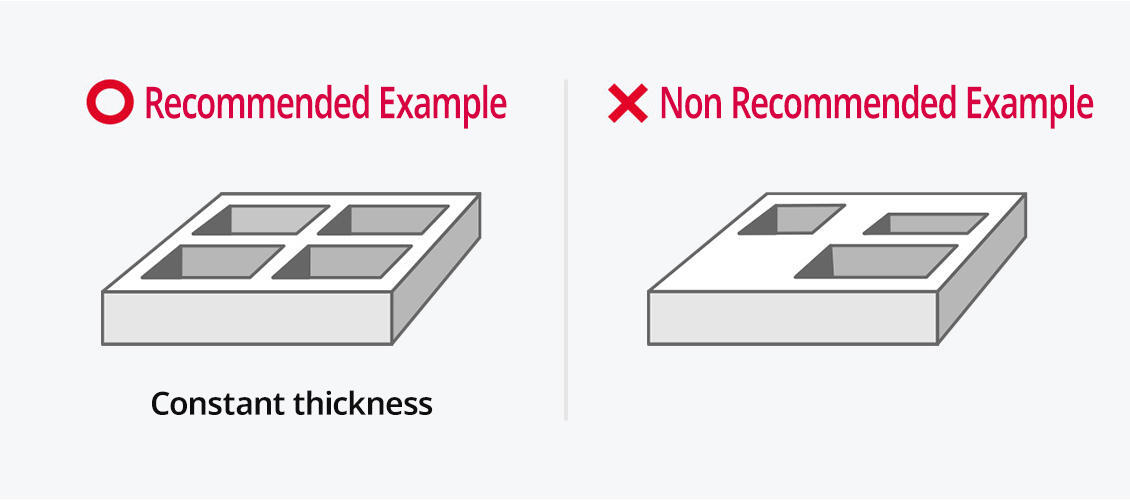

4. Pay attention to thermal shock

Fine Ceramics are vulnerable to thermal shock, so it is necessary to pay attention to quick temperature changes during use, and to consider keeping the thickness of the parts constant, etc. where possible.

5. Pay attention to the usage environment (temperature conditions, temperature changes, etc.) when combining with other materials

Fine Ceramics have a low coefficient of thermal expansion, so pay attention to the temperature environment when combining them with other materials.