Design points considering cost

Fine Ceramics can be processed with high precision, however it is a difficult to grind material and the grinding cost is high. The less complex the shape, the lower the cost.

Inner diameter keyway shape

For the inner diameter keyway shape, by avoiding square grooves and providing a corner-radius groove or a full-radius groove, machining is facilitated and stress concentration is alleviated.

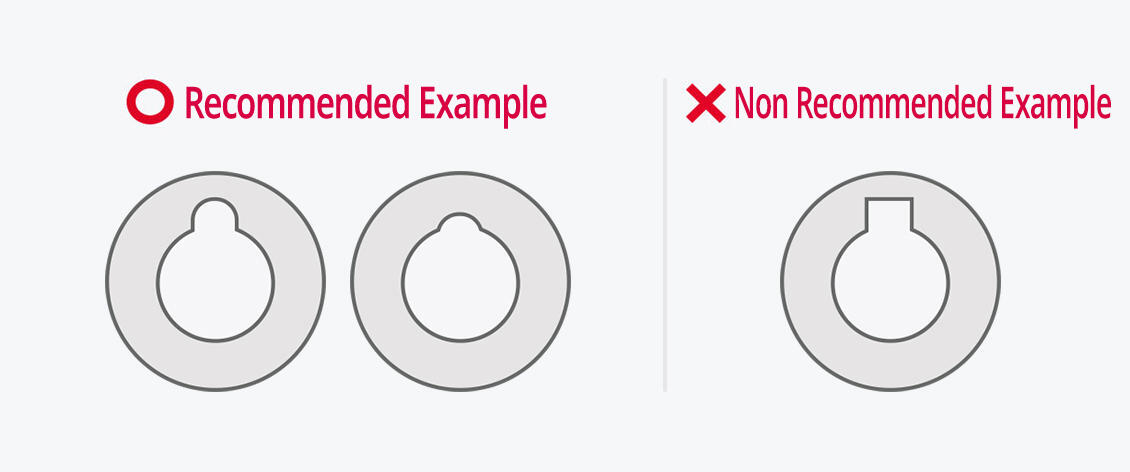

Positioning shape

For positioning shape, features such as holes, notches, slots are better because external protrusions increase the cost.

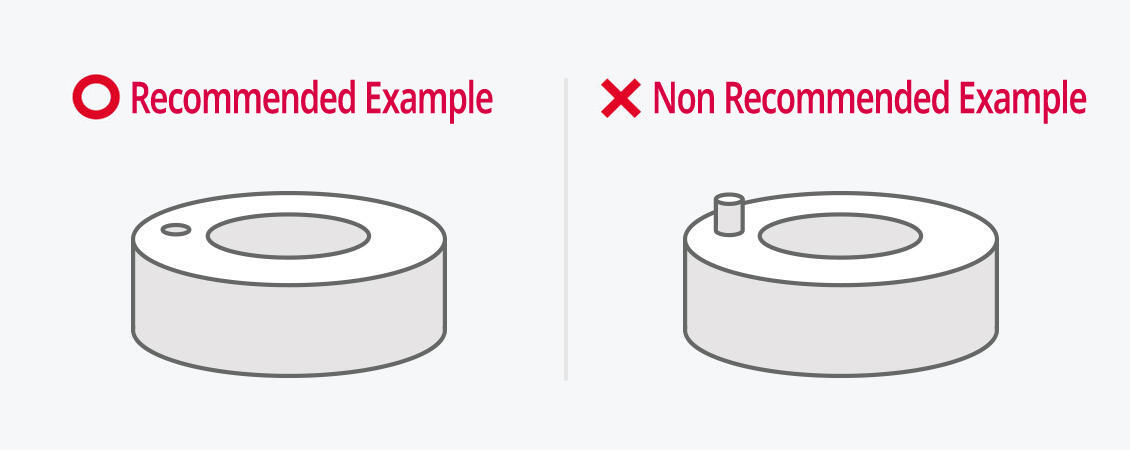

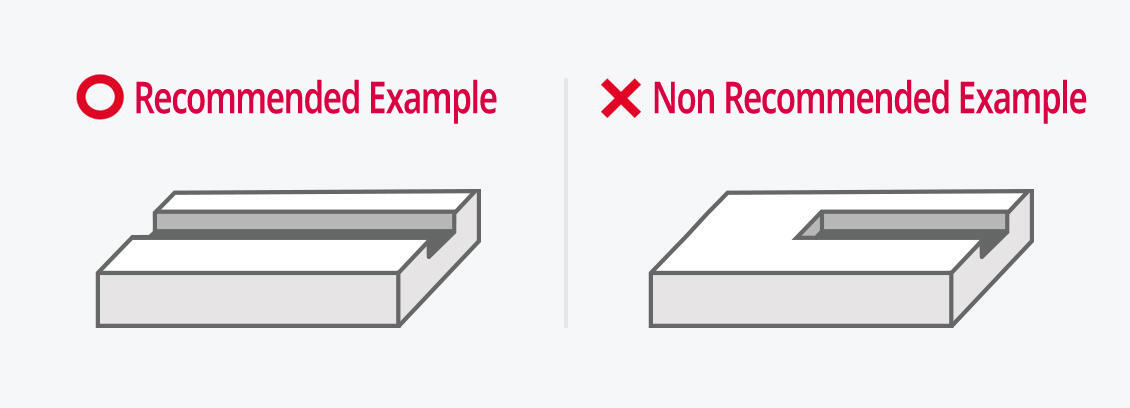

Groove shape 1

As for the groove shape, a through groove is economical, and a blind groove increases the cost.

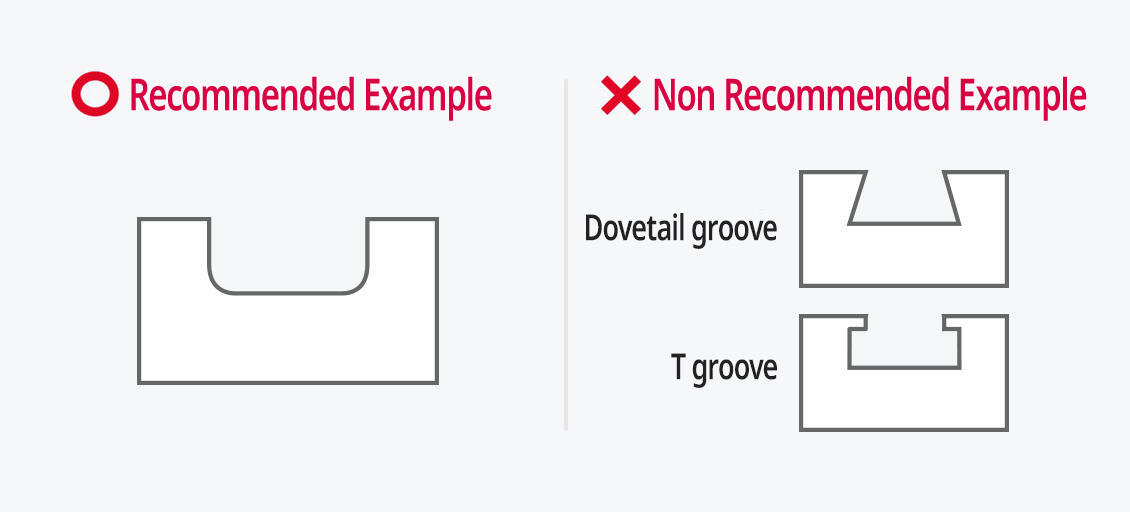

Groove Shape 2

Avoid undercut shapes such as dovetail grooves and T grooves. (A special tool - diamond wheel - is required, which increases the cost.)

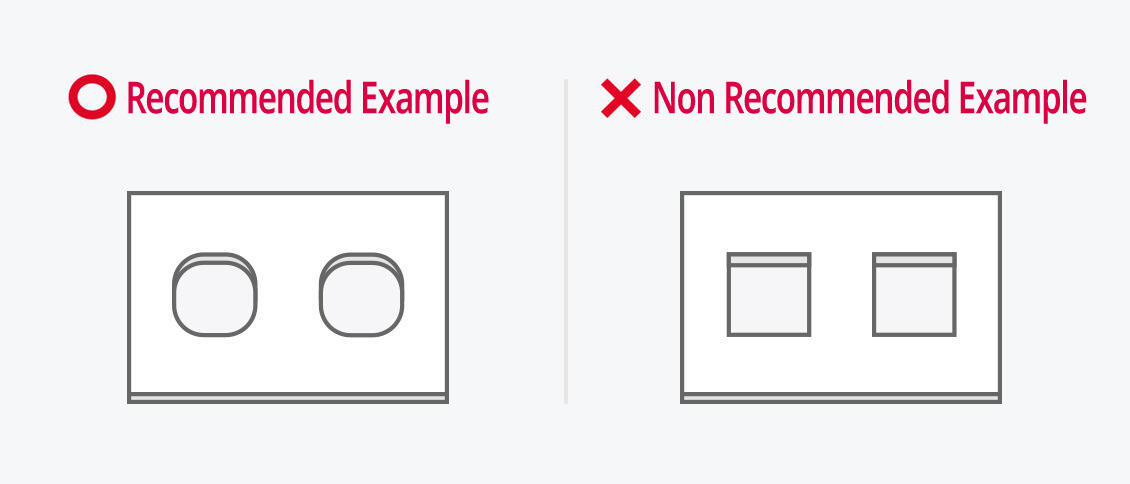

Square hole shape

For the square hole shape, the corner of the hole is difficult to make at a 90-degree angle, and the radius should be as large as possible where possible.

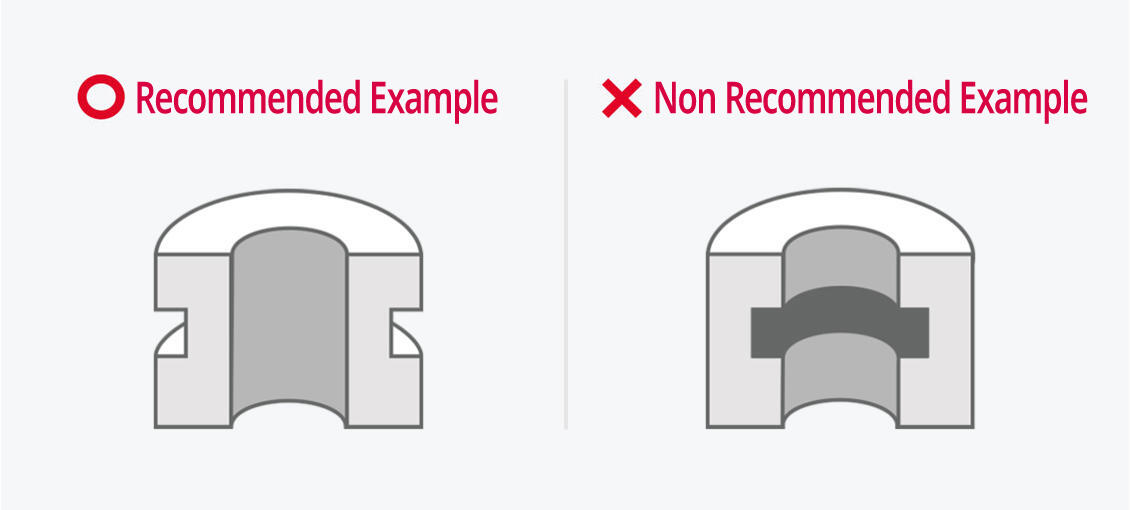

Inner and outer diameter groove shape

In the case of the inner and outer diameter grooves, machining is better to be reduced on the inner diameter side as possible and adjusted by the outer diameter shape. Inner diameter machining is more costly than outer diameter machining.