Ceramic Substrates and Packages for Indoor / Outdoor Lighting

Light Emitting Diodes (LEDs) have a shorter lifespan when exposed to high temperatures, so managing the heat they generate is crucial. Kyocera provides ceramic packages and substrates with higher thermal conductivity that can dissipate heat from LEDs efficiently.

Features

Higher Thermal Dissipation

High Thermal Conductivity

High Thermal Conductivity

Cavity Structure / Design Flexibility

Simplifies Resin Potting

Simplifies Resin Potting

Hermetic Sealing

Protects from Outside Influence

Protects from Outside Influence

Various Plating Layer Options

Concept

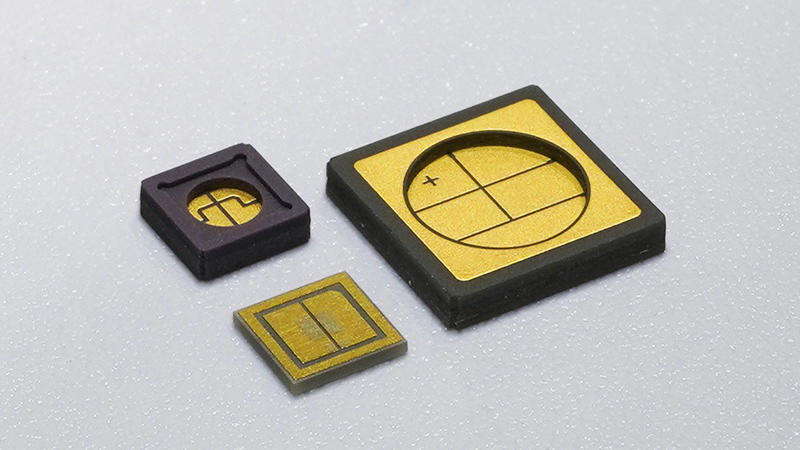

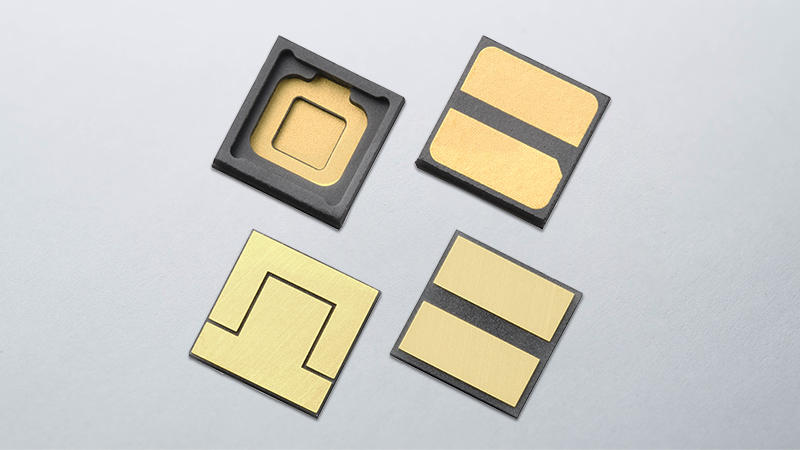

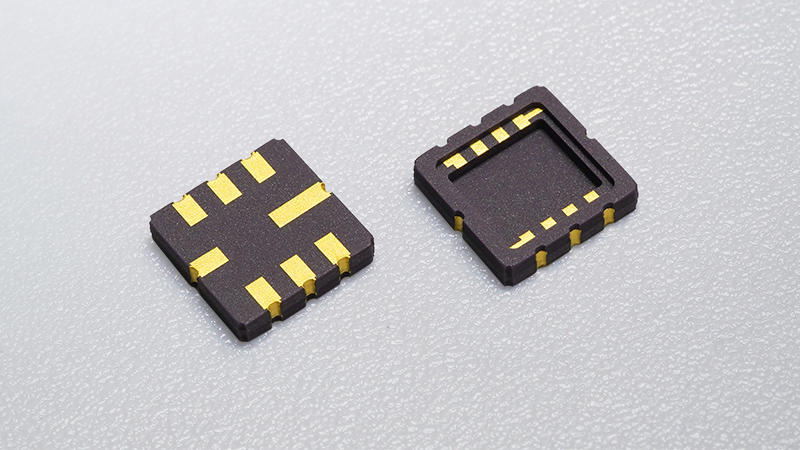

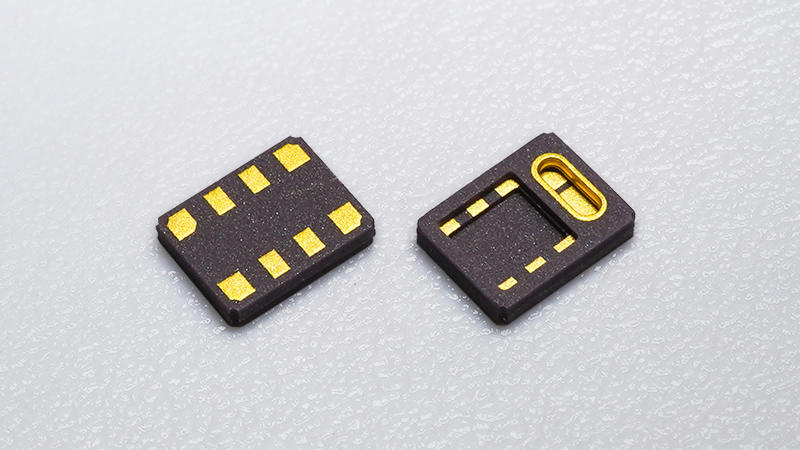

Surface-Mount Multilayer Packages (Alumina / Aluminum Nitride)

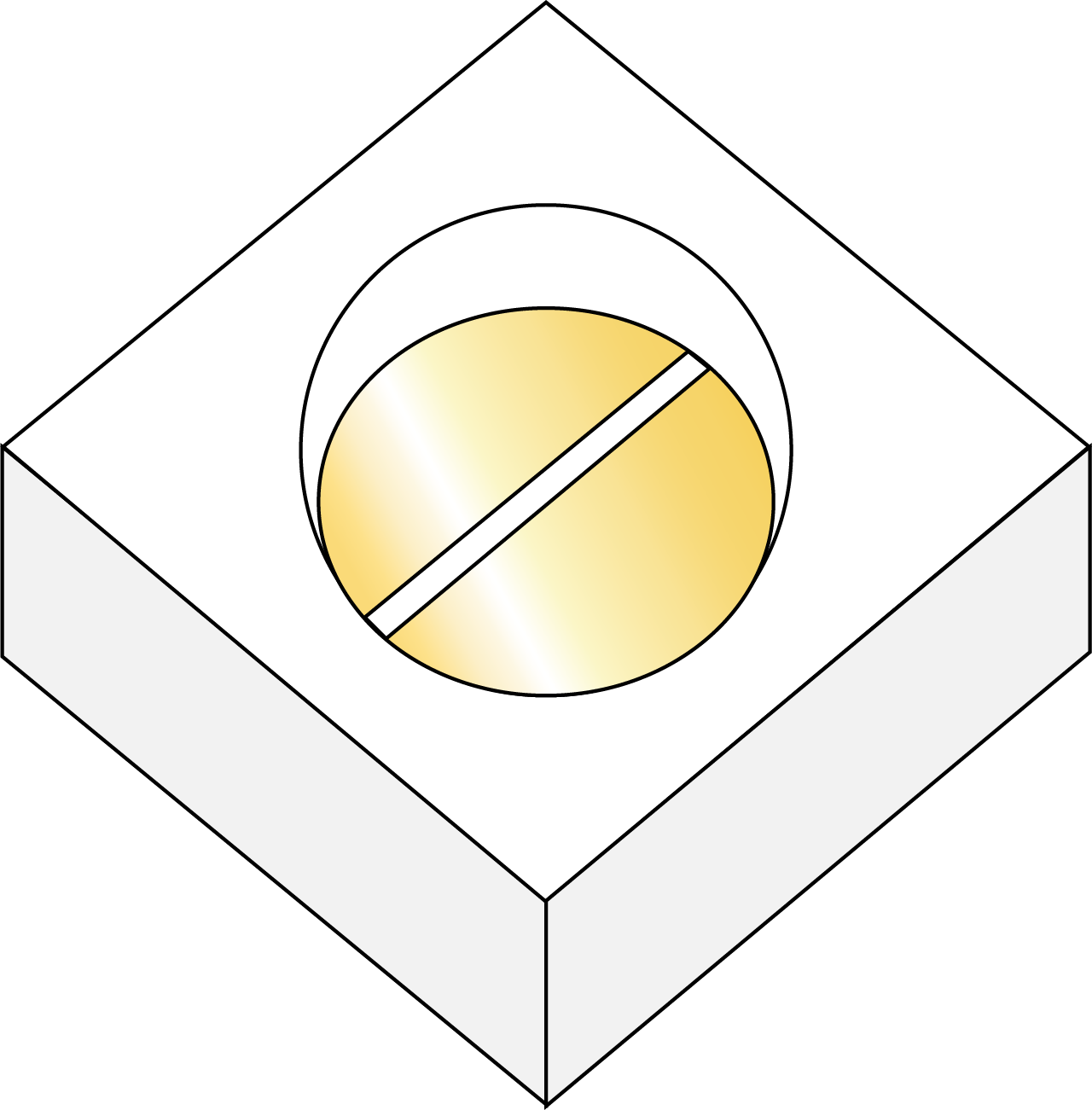

Round Cavity

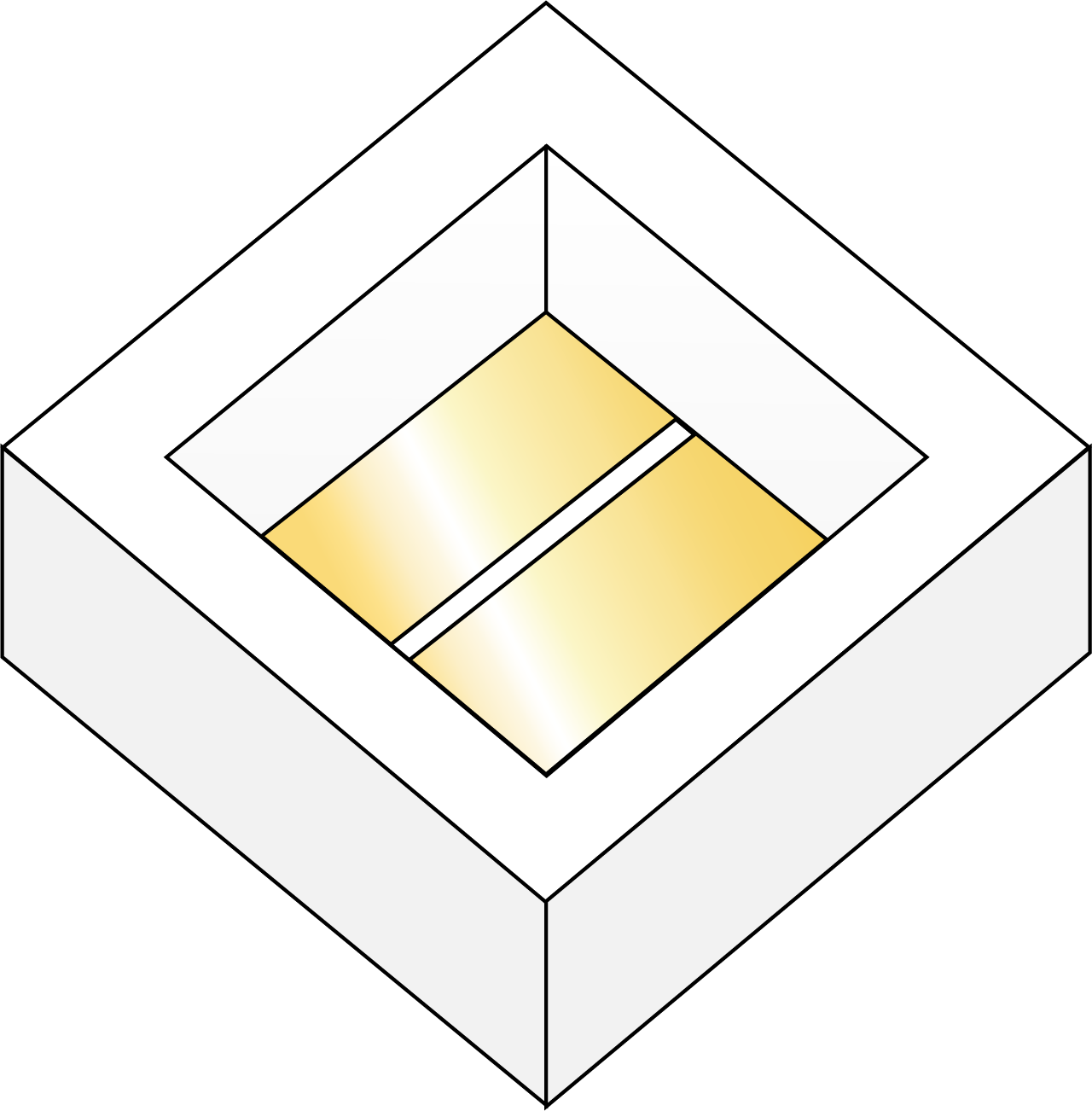

Square Cavity

Hermetic Sealing

Stepped Structure for Lid Placement

(Cross-section)

Easy lid placement for sealing

Easy lid placement for sealing

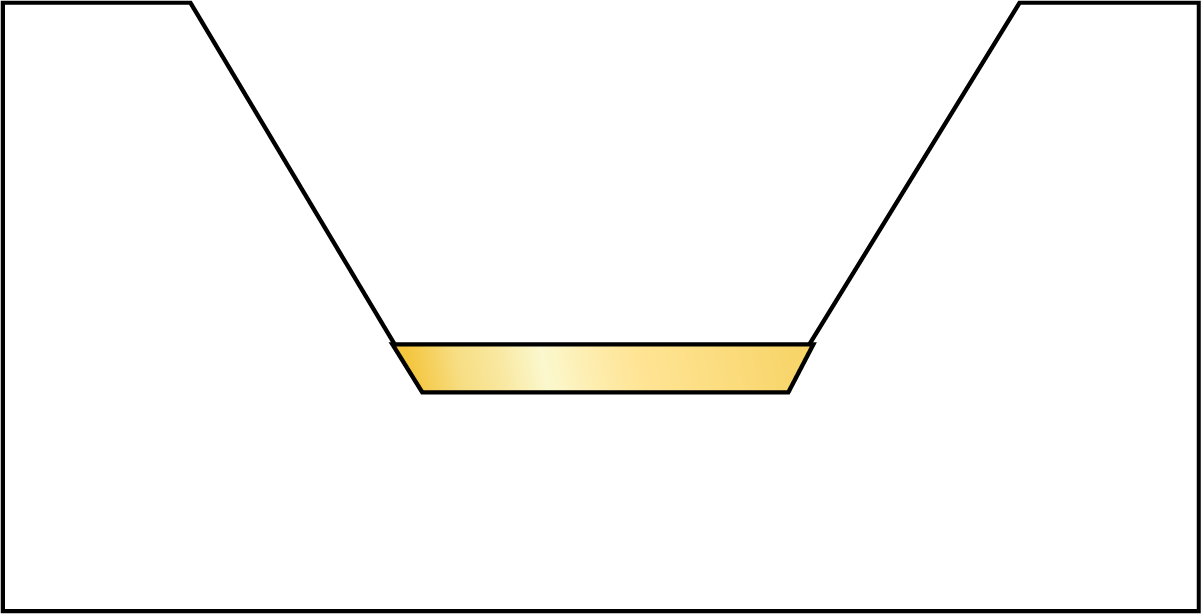

Angled Cavity

(Cross-section)

Cavity walls serve as reflectors

Cavity walls serve as reflectors

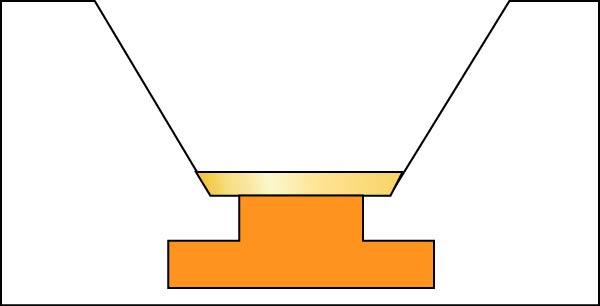

With Heat Spreader

(Cross-section)

Cu fittings optimize heat dissipation (Alumina only)

Cu fittings optimize heat dissipation (Alumina only)

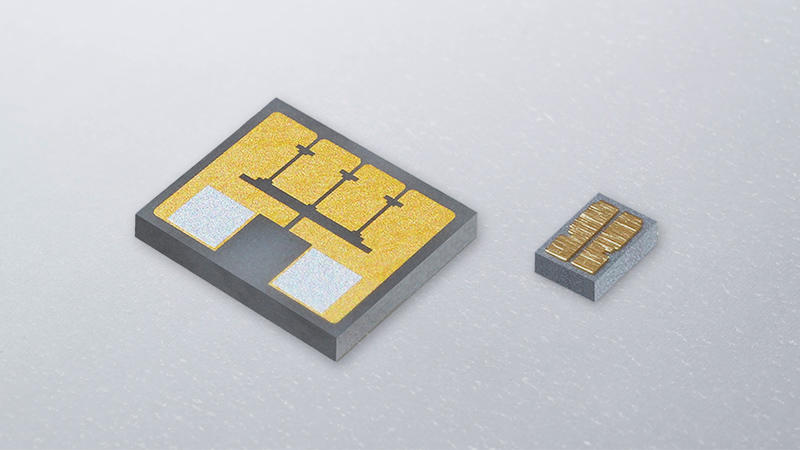

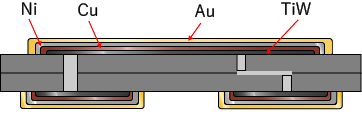

Single-Layer Thin-Film Substrates

- Available in higher heat-dissipating aluminum nitride (thermal conductivity: 170–230W/m・K).

- Plating layer configurations can be customized per different requirements.

Example: Ti-Au-Sn simplifies device mounting.

Other layer-configuration options are available here.

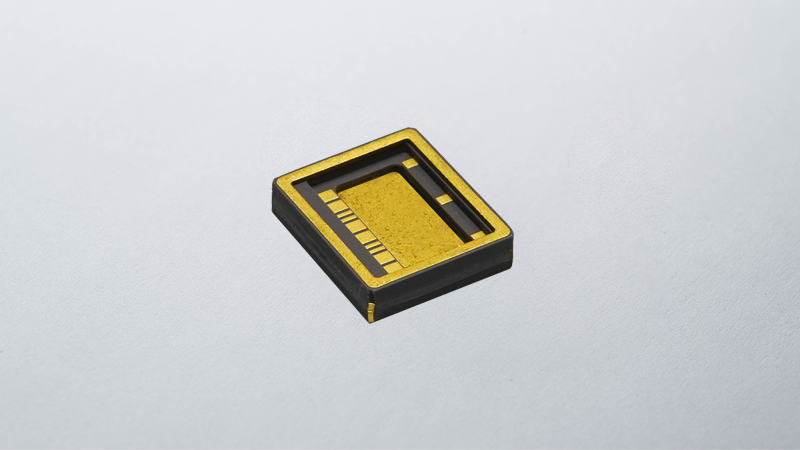

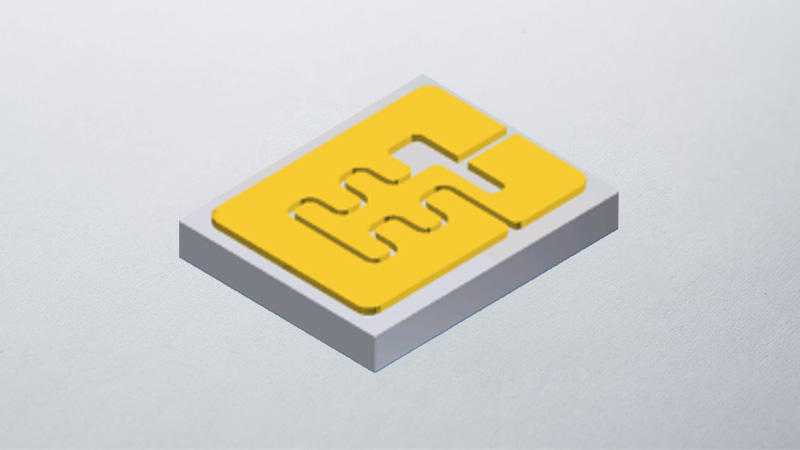

Multilayer Ceramic Substrates + Thin-Film Integration

*An example of Multilayer + Thin-Film

Thin-films can also be applied to multilayer ceramic packages and substrates, including circuit designs with 3-D routing between layers, for multi-chip or multi-element mounting.

FAQ

Materials