Co-Firing Ceramic Packages/Substrates

Overview of the Co-Firing Process

The process of hardening ceramics at high temperatures is called "sintering" or "firing."

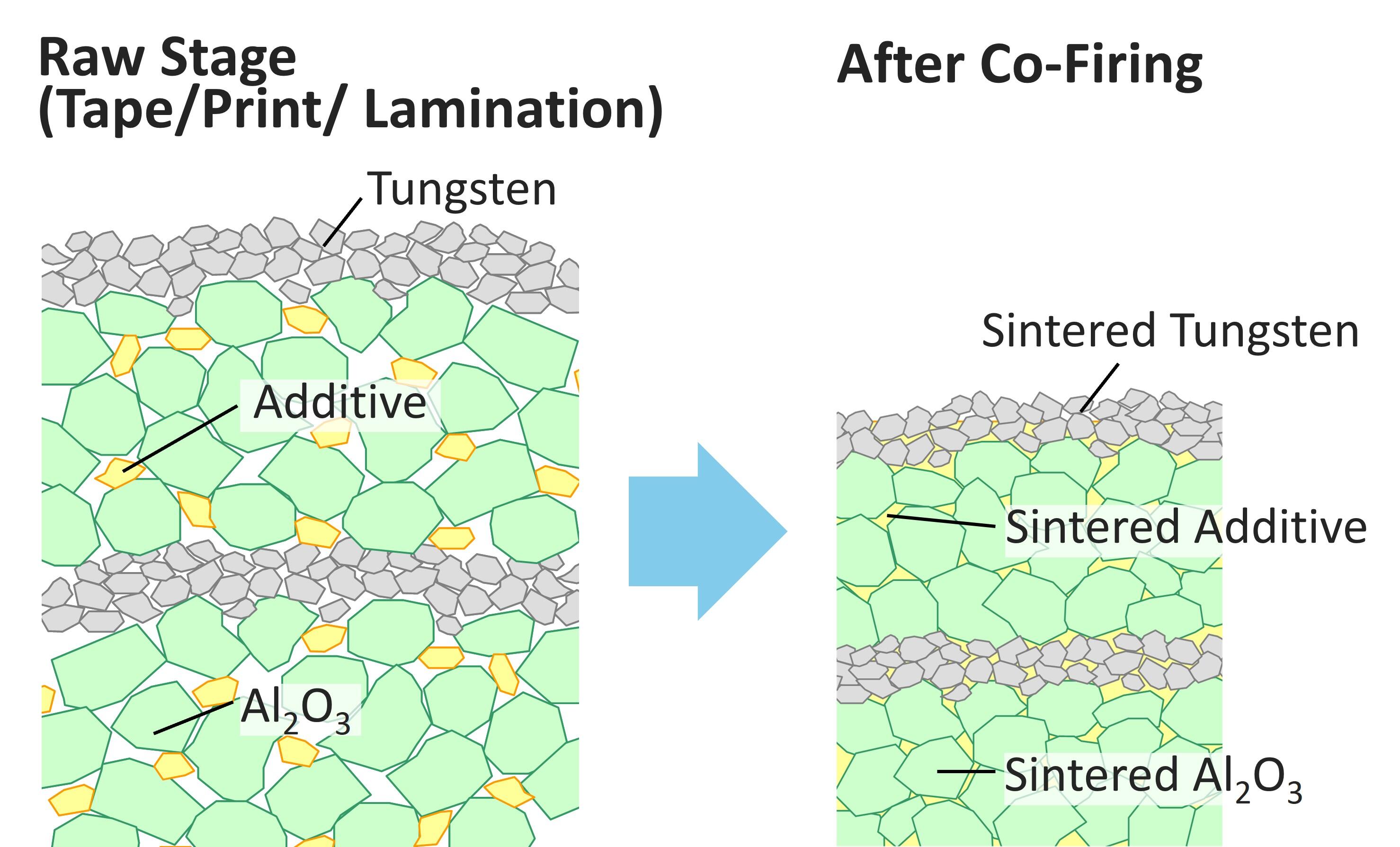

"Co-firing" is a related process in which ceramics and conductors are both fired at the same time to become a solid, integrated body, shrinking in size, as shown at right.

Kyocera's Co-Firing Technology: Evolving Over Decades

Conventional ceramics also shrink during firing, and may crack or distort in shape. In contrast, Kyocera's Fine Ceramic technology allows us to control every aspect of the manufacturing process to create ceramics with exact sizes, shapes, and physical properties.

(Cross-section) A sintered multilayer ceramic substrate showing co-fired electrical conductors connecting between layers.

Ceramic packages require co-firing because ceramics and conductors differ in physical properties. Precise control over all process parameters is necessary to make sure the conductors bond to the ceramic completely and shrink to the specified dimension and flatness. Kyocera has experience meeting extremely demanding customer requirements by applying our Fine Ceramic technology, which we have developed continuously since our founding in 1959.