Ceramic Substrates and Packages for Vertical-Cavity Surface-Emitting Lasers (VCSELs)

Laser diodes (LDs) experience shorter lifespans when exposed to high temperatures, making thermal management essential.

Kyocera's ceramic packages and substrates offer superior thermal conductivity to dissipate heat efficiently from LDs and ICs. We can provide ceramic packages and submounts tailored to a wide range of customer requirements.

Features

Superior Thermal Dissipation

Surface Mounting

Miniaturization

Design Flexibility

Hermetic Sealing

Various Thin-Film

Options

Options

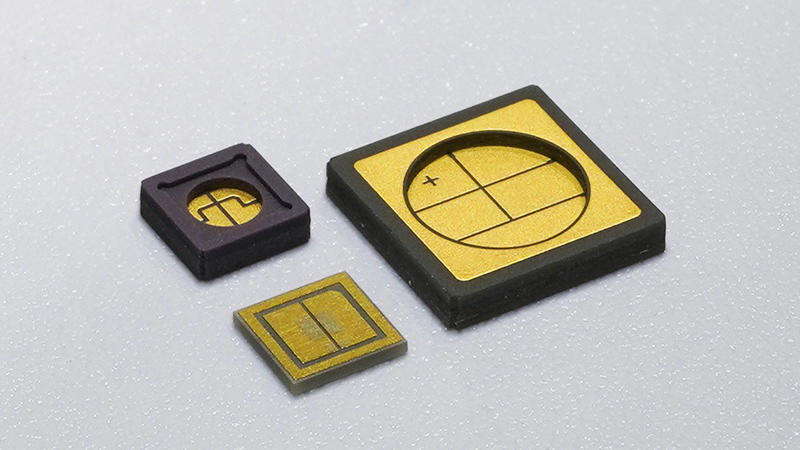

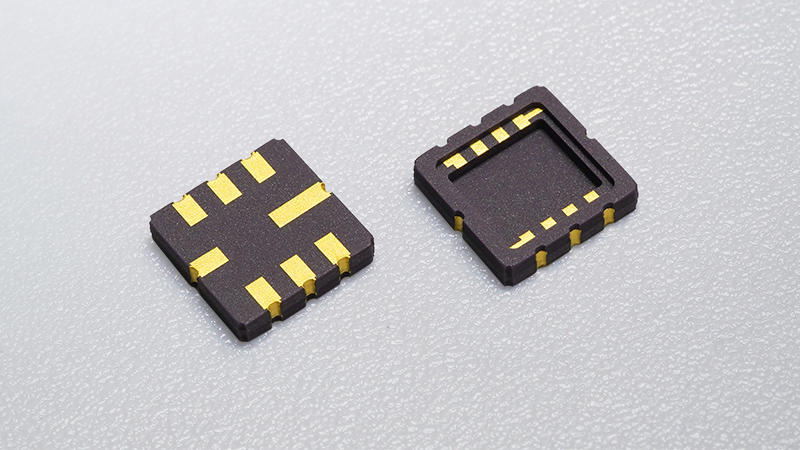

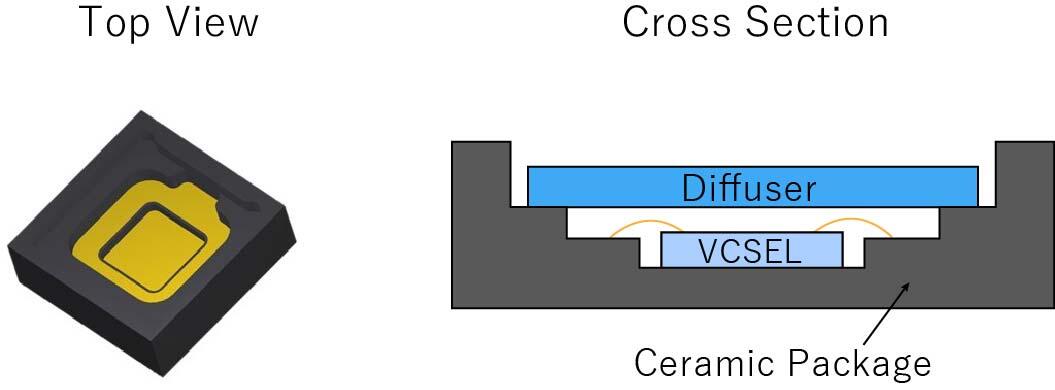

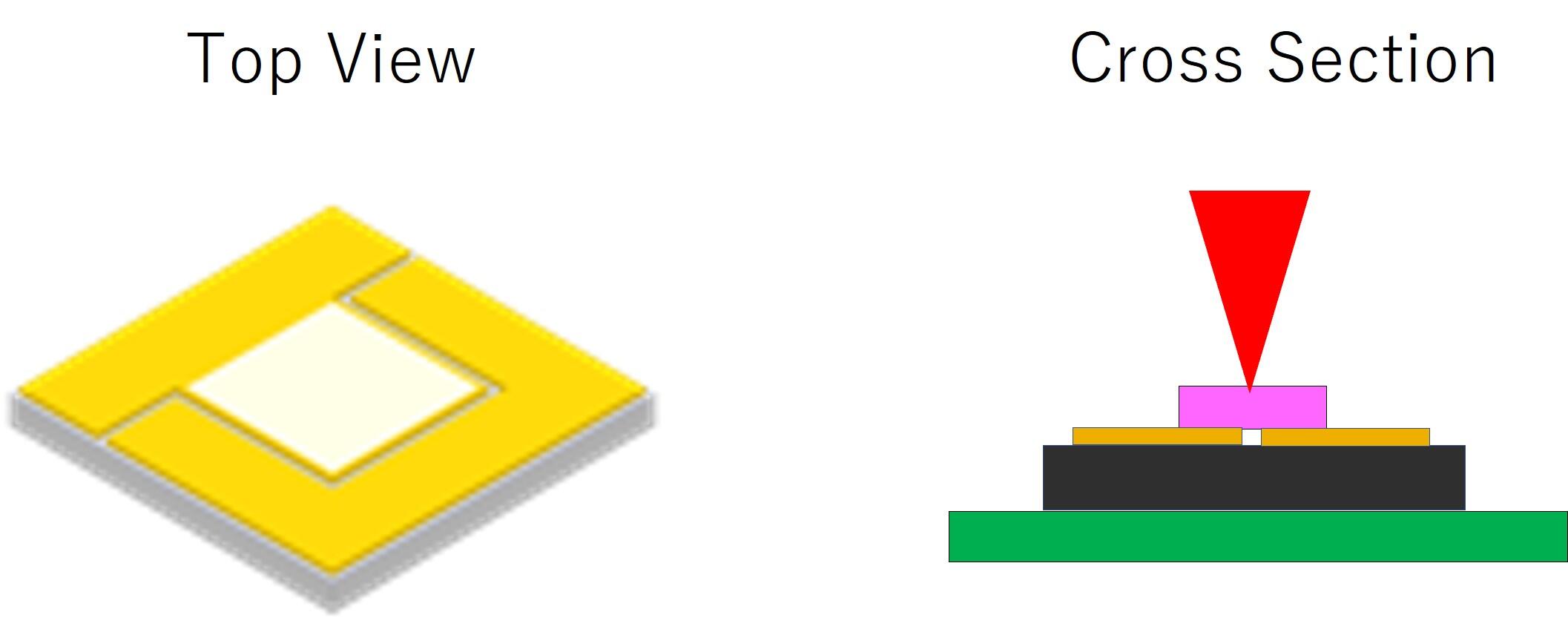

Surface Mount Ceramic Multilayer Package

Examples

Features

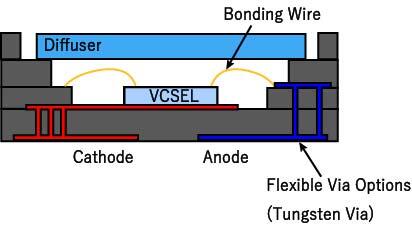

- Multilayer ceramic packages enable cavity structures.

- Hermetic sealing options are available.

- Inductance/resistance can be improved by increasing the number of vias.

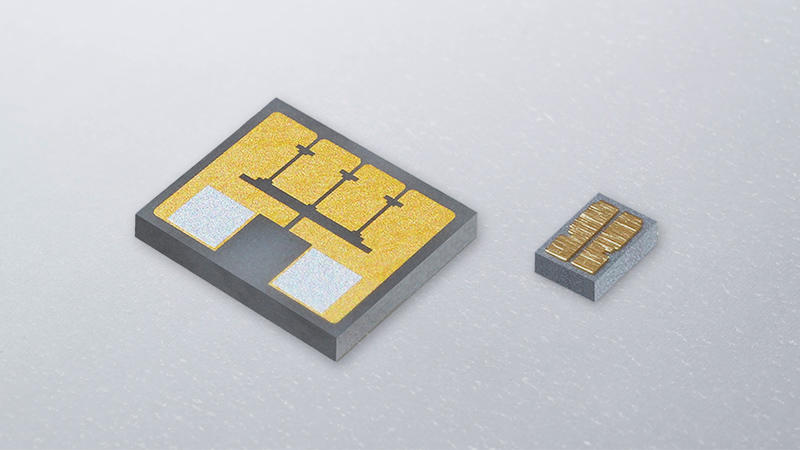

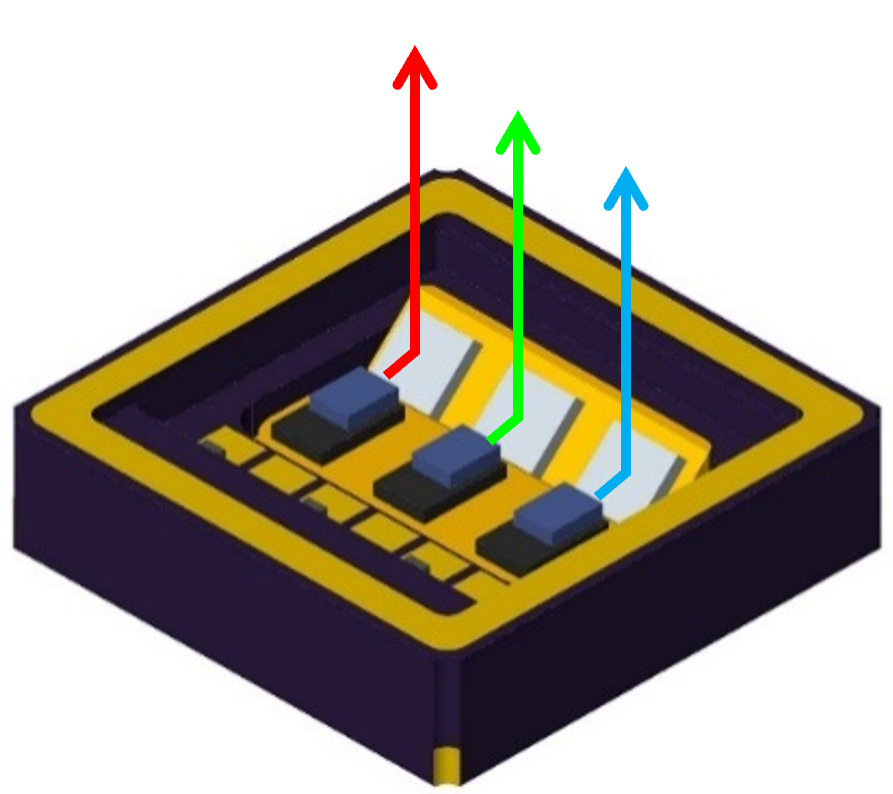

Low Inductance/Resistance Design

- Shelf structure minimizes bonding wire length.

- Multilayer ceramic package design allows a multitude of vias.

→Decreases package inductance.

→Reduces device pulse width.

→Increases laser output strength/pulse frequency

⇒Contributes to long-distance/high-resolution pulse lasers.

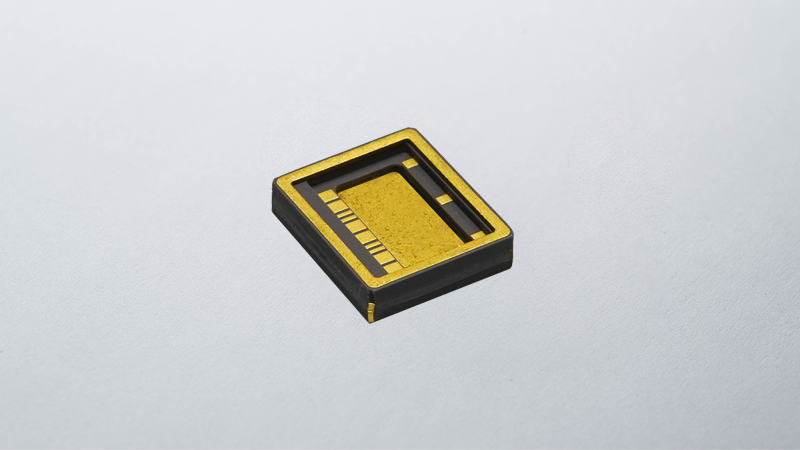

Additional Function

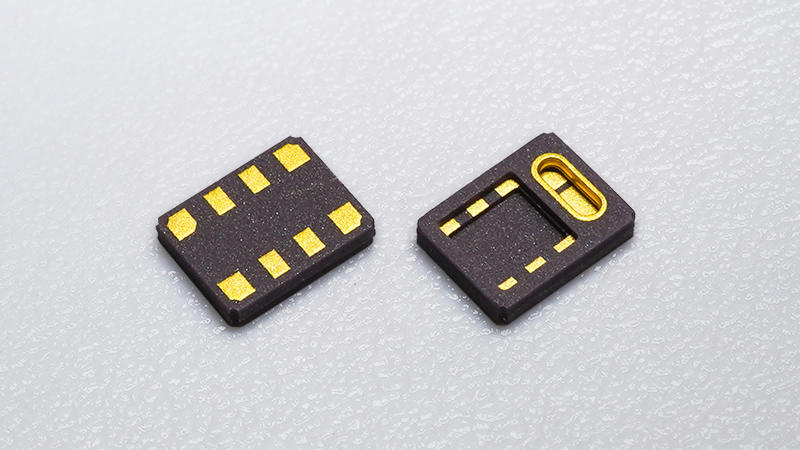

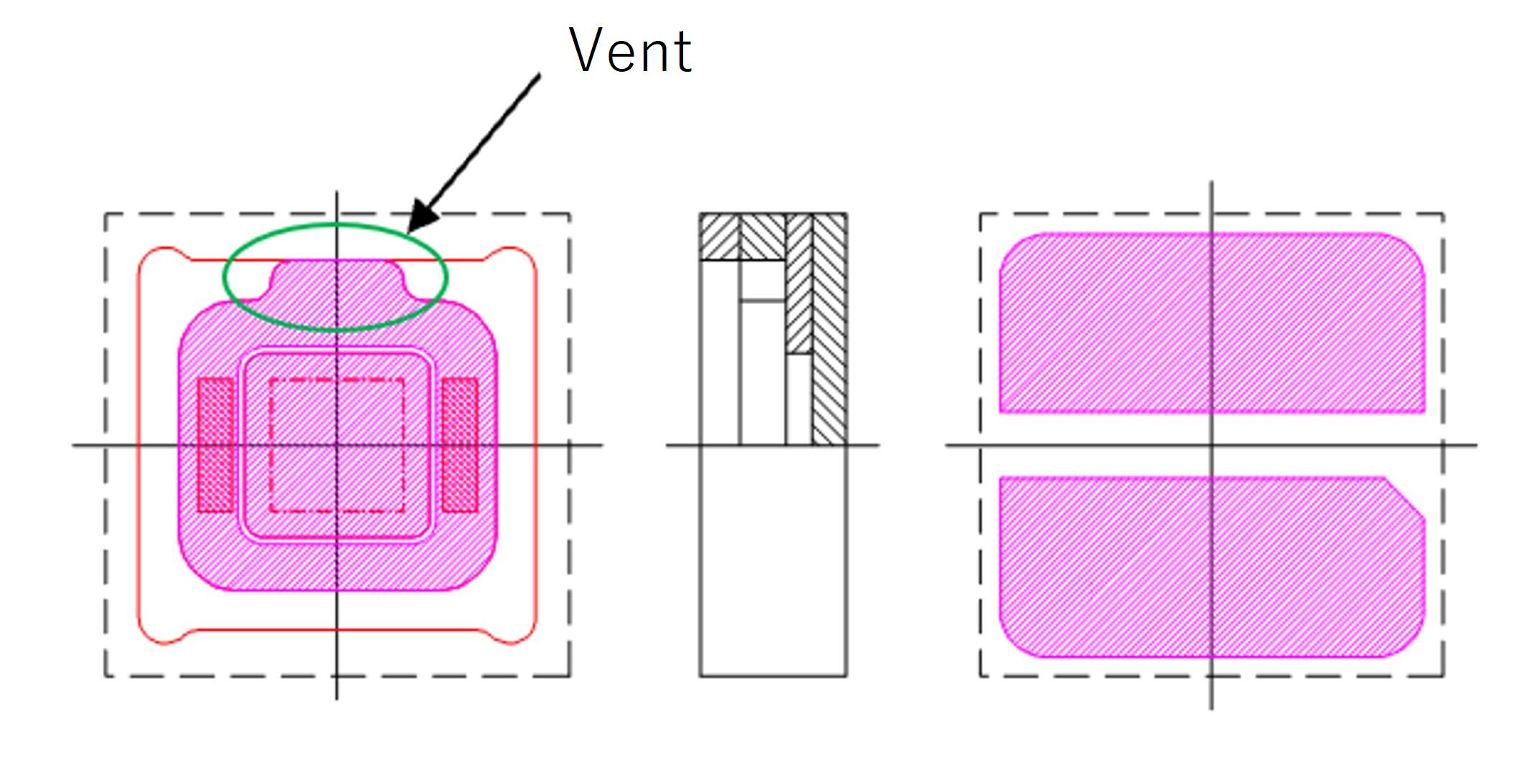

Vents

- The customized cavity shape allows the formation of vents.

(Vent: A hole to release gases from adhesives and other materials during diffuser installation.)

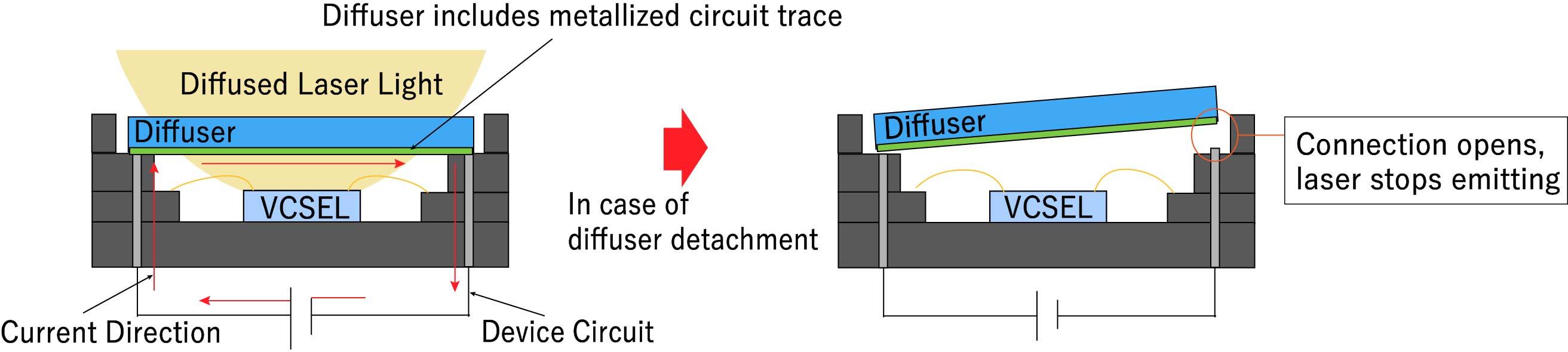

Eye Safety

By utilizing 3D routing, a single safety circuit can be formed through the diffuser, package, and VCSEL. In the case of diffuser detachment, the VCSEL loses power, preventing harmful irradiation.

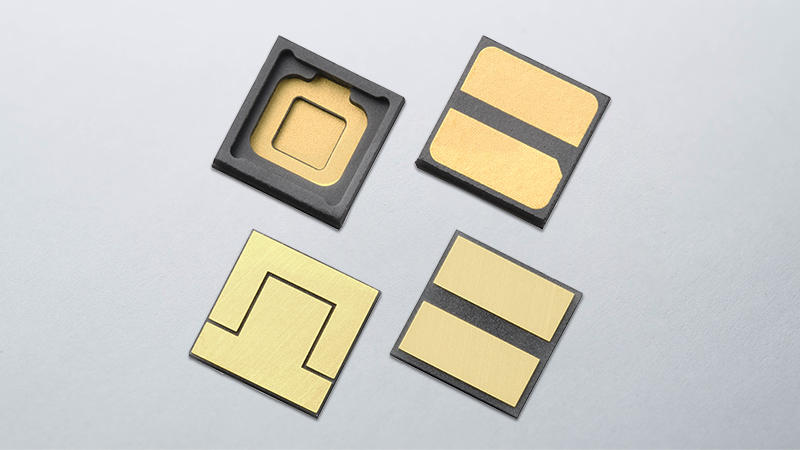

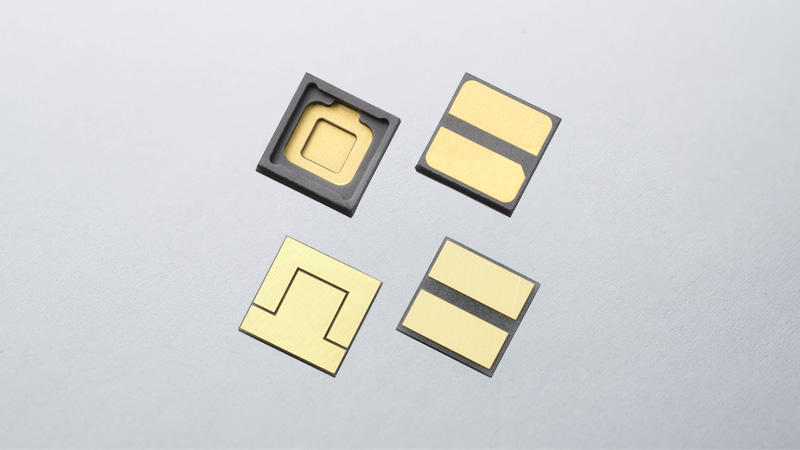

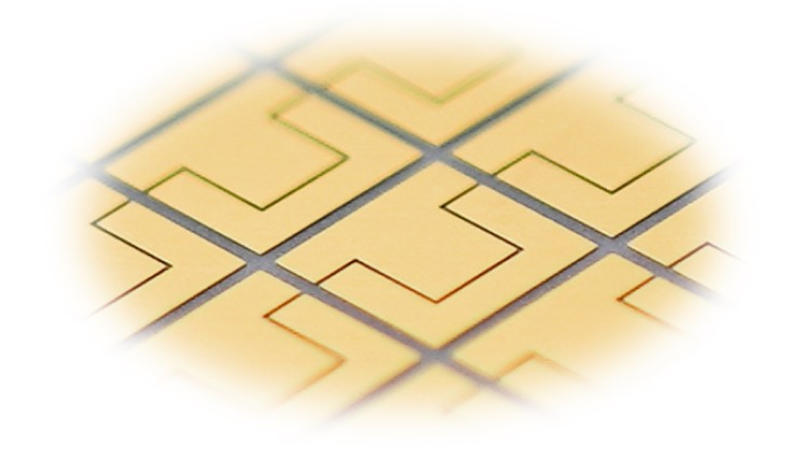

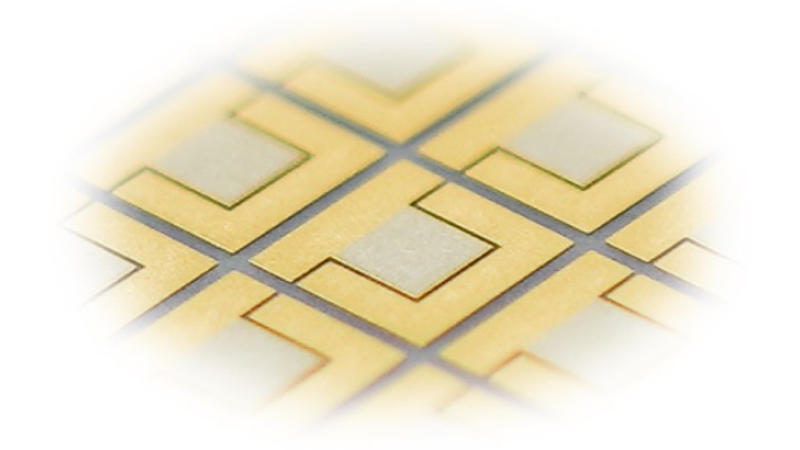

Laser Submounts

Features

- Coatings are applied to the polished flat surface, minimizing optical axis deviation.

- Optional AuSn deposition is available, which eliminates AuSn preforms for assembly.

Without AuSn deposition

With AuSn deposition