Thin-Film Submounts for Laser Diodes

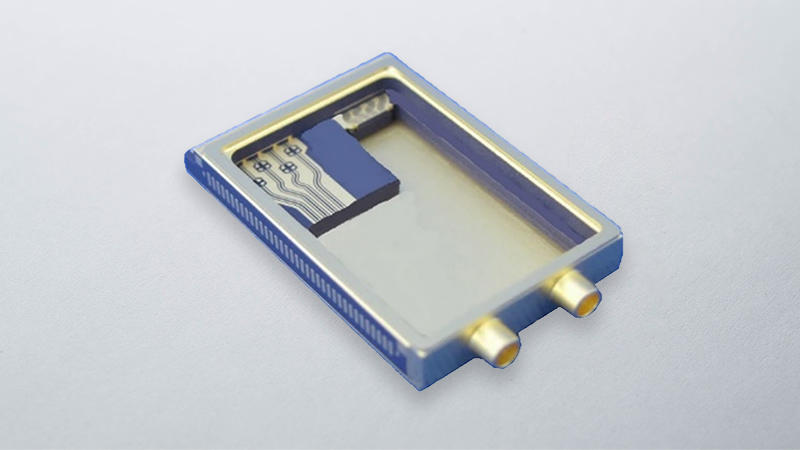

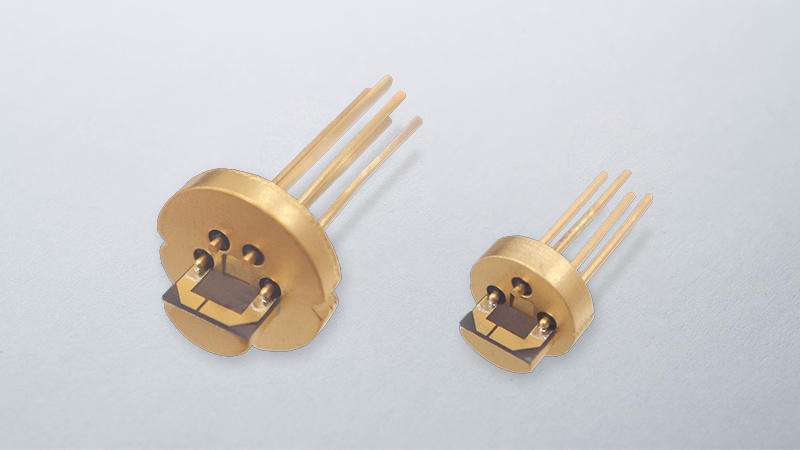

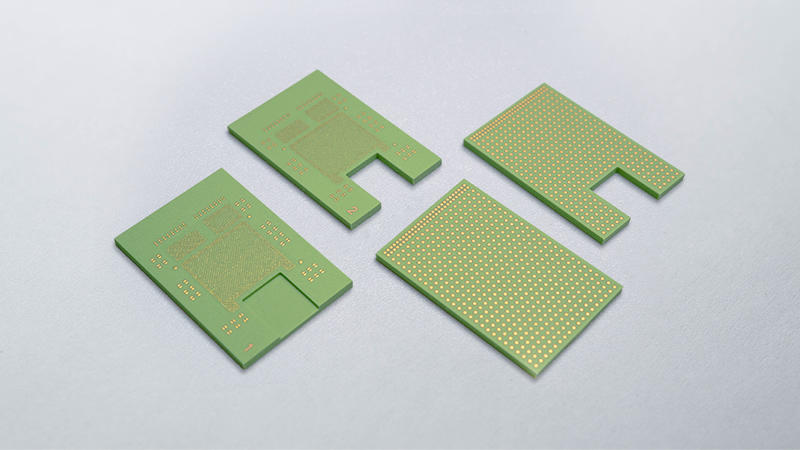

Aluminum nitride (AlN) is one of the most thermally conductive ceramic materials. In optical communication modules, the trend toward greater miniaturization and integration is making aluminum nitride essential as a submount material for laser diodes (LDs), which generate high levels of heat. Kyocera can create single-layer or multi-layer substrates in various shapes and structural designs according to your needs.

Features

Ceramics: Enabling Higher Power Output

As a submount material, aluminum nitride (AlN) offers very high thermal conductivity, which can dissipate heat from high-power ICs efficiently. Additionally, AlN improves semiconductor laser reliability through its high electrical insulation resistance and its coefficient of thermal expansion (CTE), which is closer to that of silicon, the most common semiconductor device material, thereby reducing stress to laser diodes and improving long-term reliability.

*Aluminum oxide (alumina Al2O3) is also available.

Design Flexibility

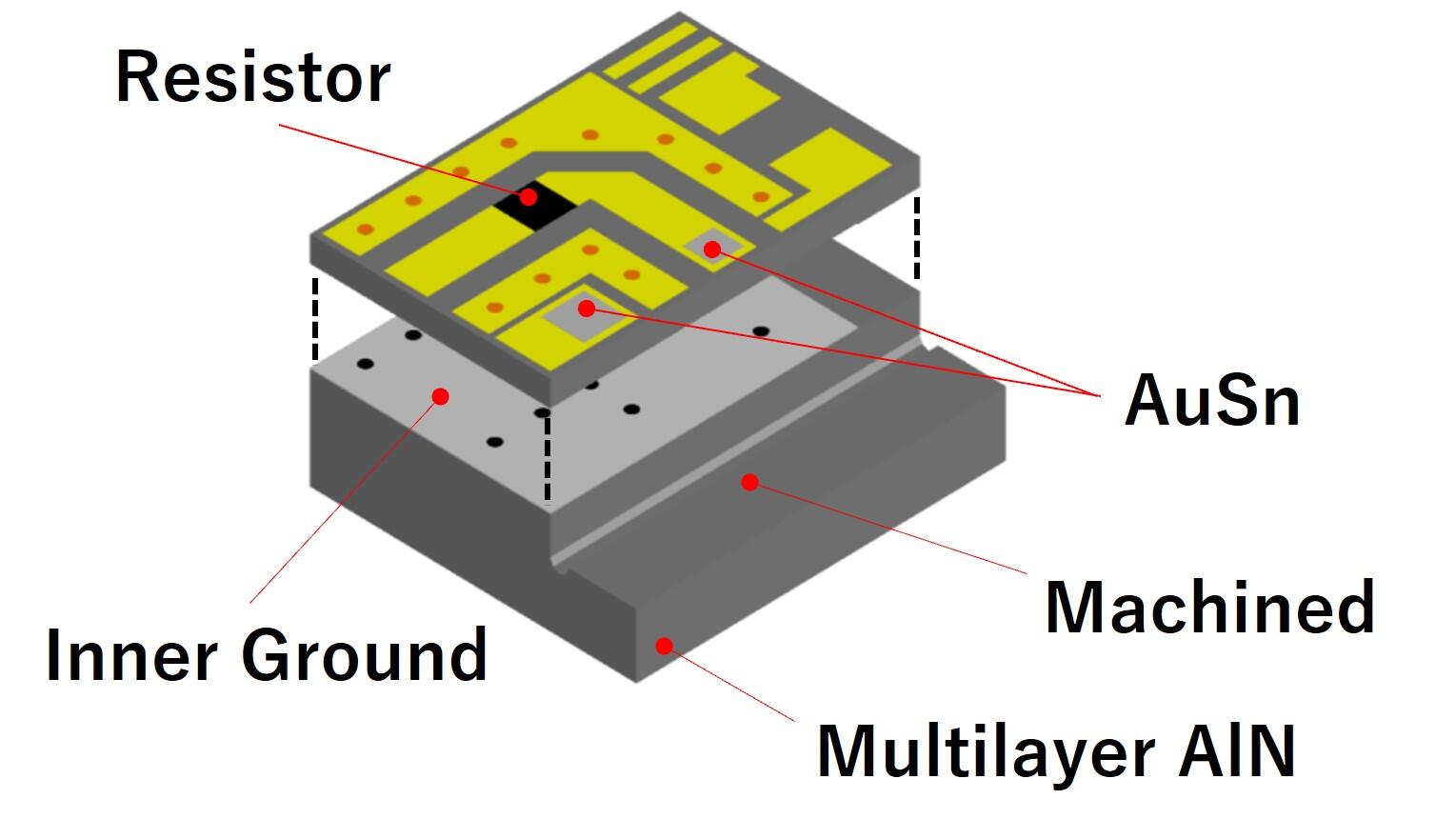

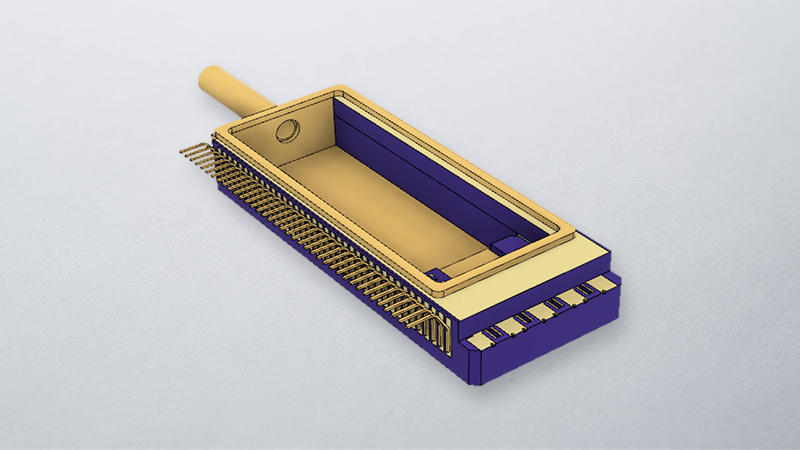

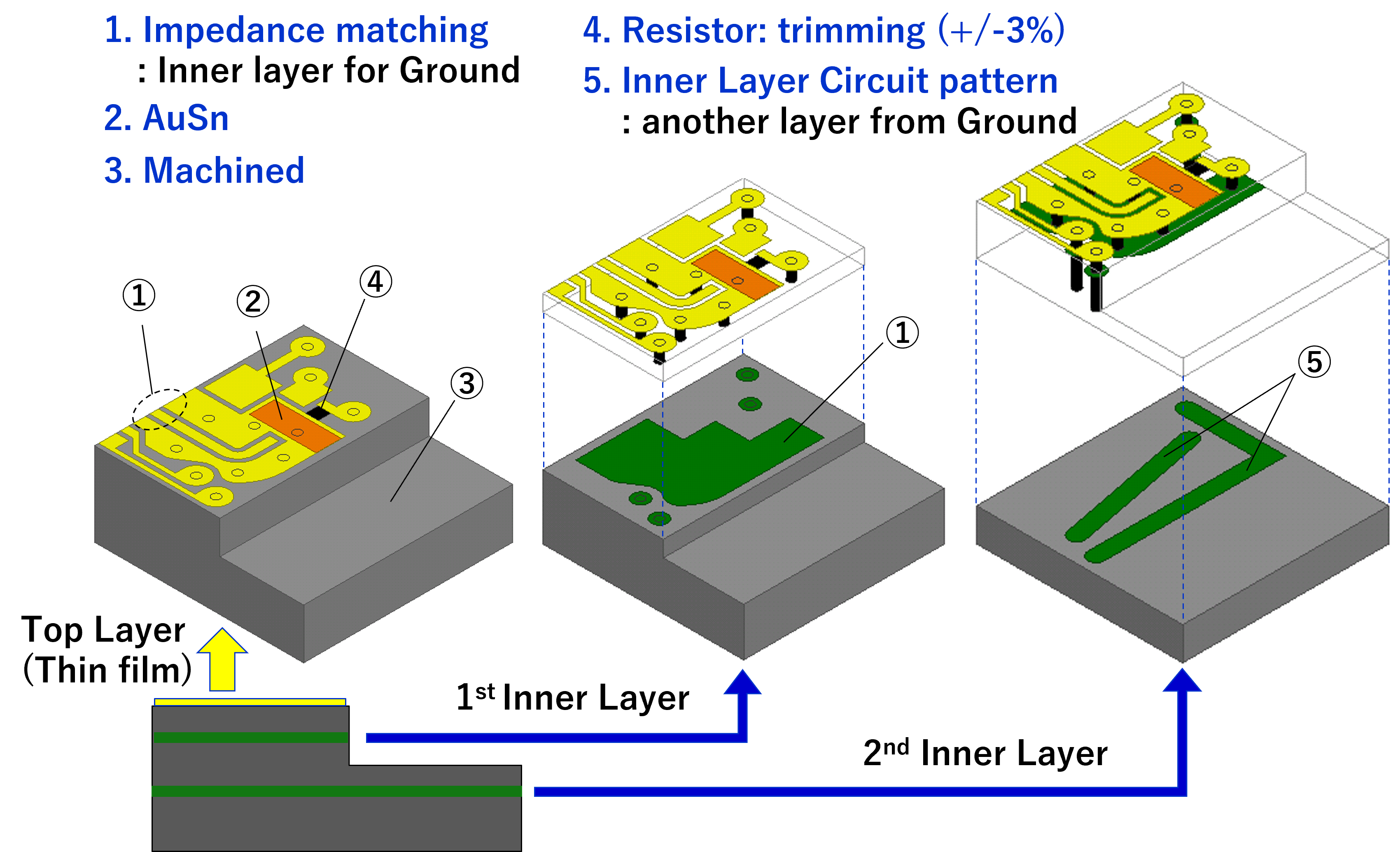

A ceramic substrate’s inner layer can be used for a ground pattern to achieve impedance matching, or for a circuit pattern. Kyocera can design special shapes and structures for miniaturization, lower profiles, and finer circuit patterns.

[Example]

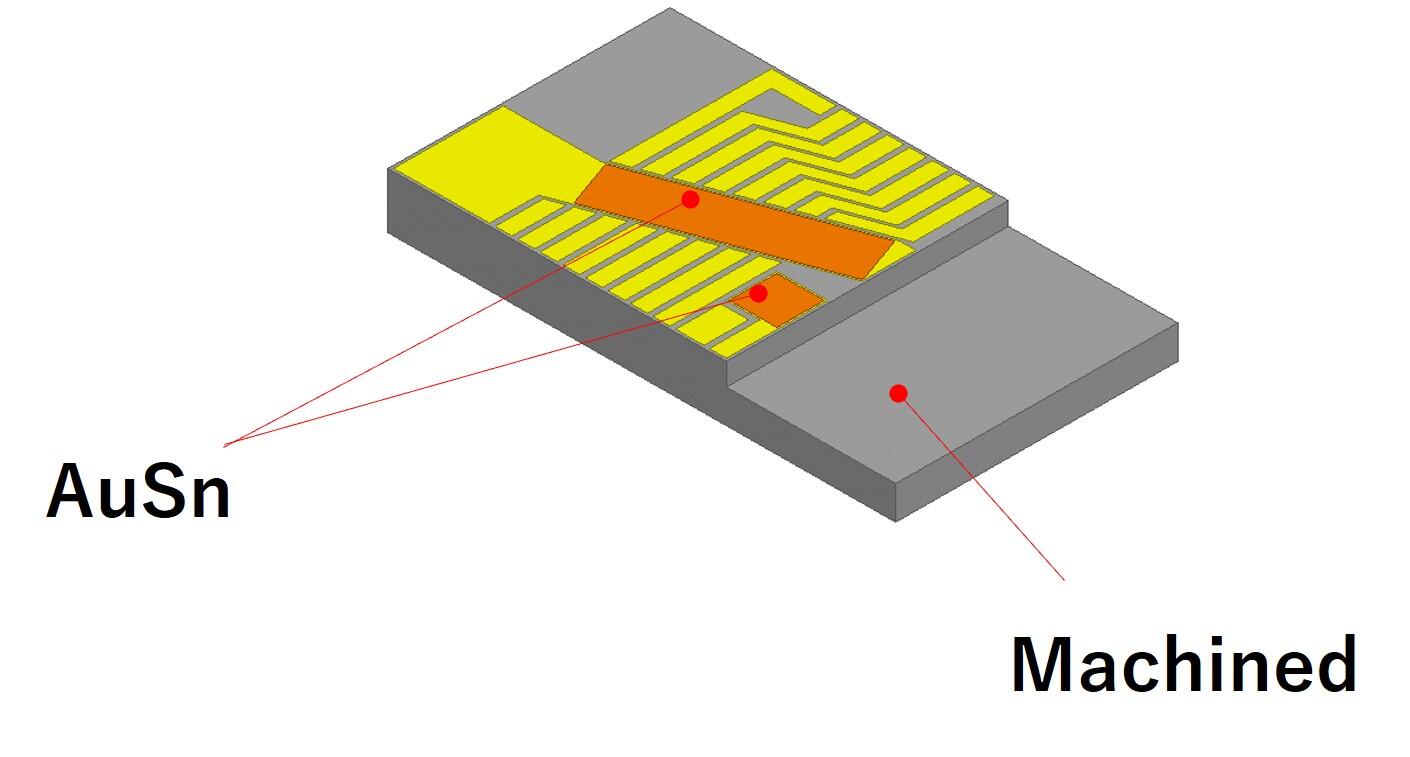

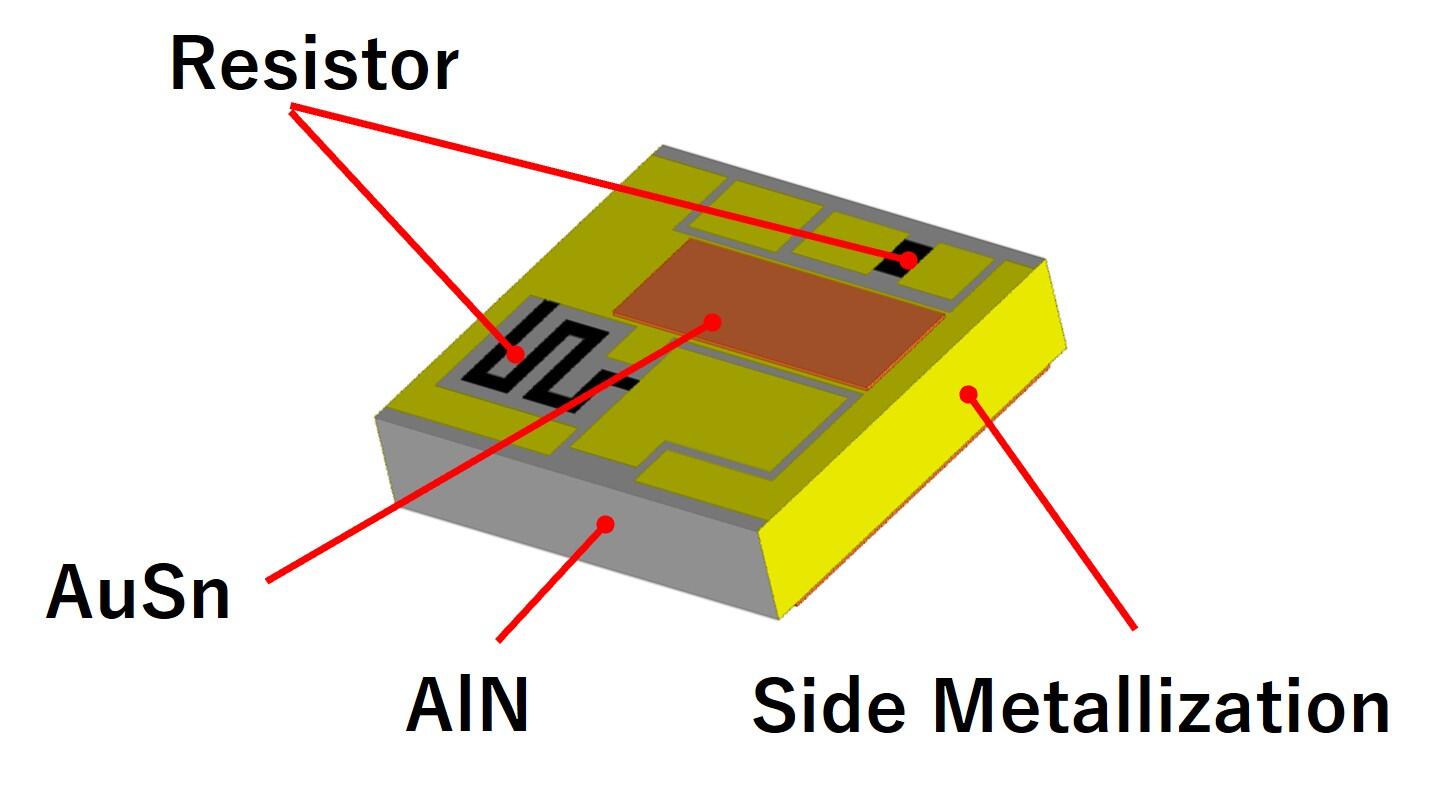

- Side metallization

- AuSn deposition

- Resistor patterns to be trimmed

- Machining

Example