Demand for MEMS (Micro Electro Mechanical System) microphones is rising as these devices expand into new applications, such as smartphones, tablets, wearable devices, wireless headsets, and smart speakers. Kyocera provides ceramic packages in thin designs that enhance microphone sensitivity and enable further miniaturization.

Features

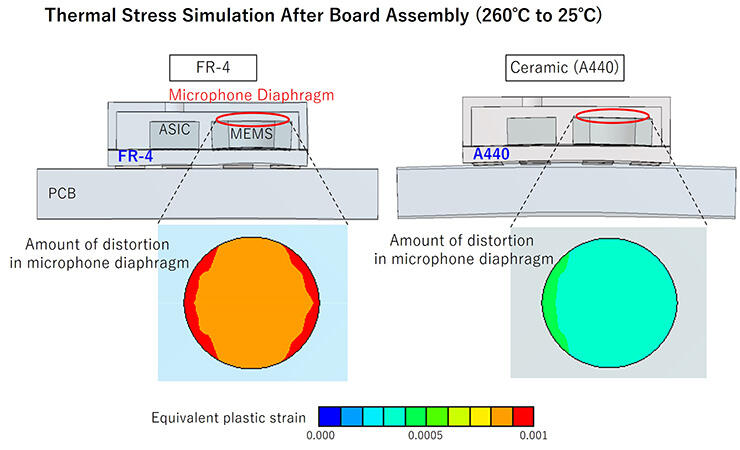

Material Properties: CTE and Young's Modulus

Ceramic exhibits a coefficient of thermal expansion (CTE) close to that of silicon, and a relatively high modulus of elasticity (Young's modulus). Together, these properties help minimize deformation to enhance the sensitivity of microphone elements.

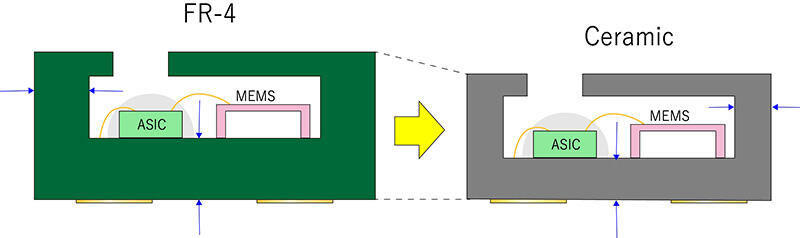

Miniaturization and Thinner Packages

Ceramic's high rigidity reduces the deformation of the MEMS device, allowing the microphone to maintain high sensitivity even when mounted on a very thin substrate. In addition, compared to FR-4 composite material, ceramic packages can have thinner walls and thinner bottom layers, which facilitates miniaturization.

Water Resistant / Dust Resistant Concepts

Kyocera's unique microfabrication technology can allow smaller through-holes to enhance the water- and dust-resistance of MEMS microphones. Please contact us for details.