Challenge: Protecting ICs and Miniaturizing Devices

An IC package must protect the IC from environmental factors, such as mechanical stress. Consequently, high rigidity and strength are key attributes of any packaging material. Additionally, to miniaturize devices, materials must be strong enough to remain rigid even as package walls and bottom layers are made thinner.

Advantages of Using Materials with High Rigidity and Strength

The high rigidity and strength of ceramics can minimize device deformation caused by mechanical stress and heat.

Minimizing IC chip deformation from mechanical stress

Ceramic materials possess high rigidity and strength, making them resistant to deformation when external forces are applied. Because of this, they can protect IC chips from external pressure and other forces.

Minimizing IC chip deformation caused by heat

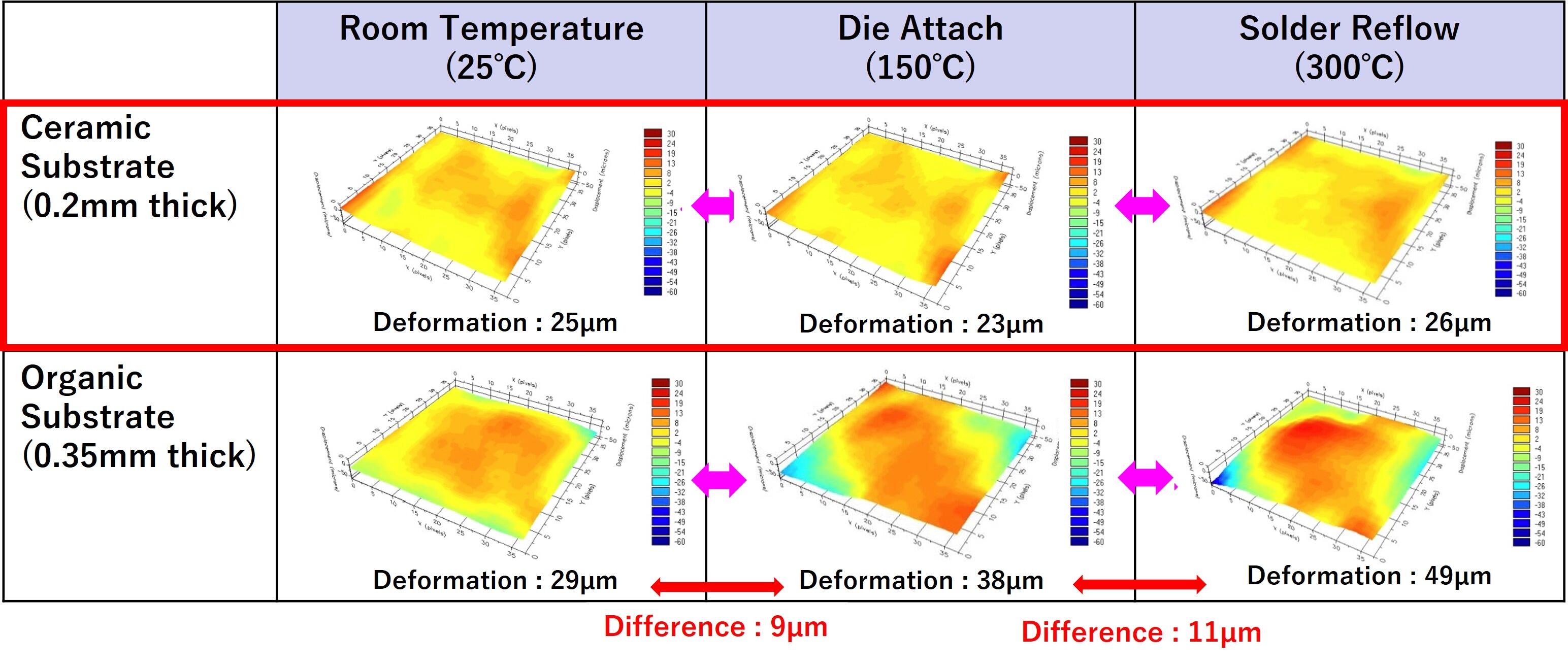

Compared to organic materials, ceramics resist deformation at high temperatures. Below are the experimental results of heat applied during the IC assembly process comparing ceramic and organic substrates. Results show that ceramic substrates exhibit less deformation than organic substrates, making ICs packaged in ceramic less likely to experience deformation-related defects.

Substrate Deformation (10x10mm)

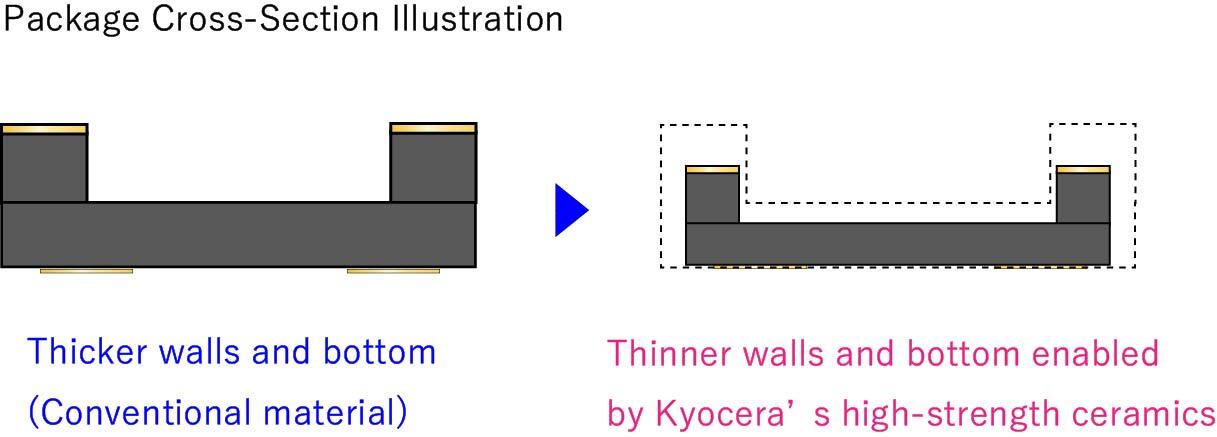

Miniaturizing Devices with High-Strength Materials

The higher flexural strength of ceramic can allow ceramic packages to be strong and rigid even with thinner bottom layers and narrower walls, which is the key to miniaturization.