Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Strength (1)

Extreme Hardness Surpassing that of Metals

The signature feature of Fine Ceramics (also known as "advanced ceramics") is their extreme hardness; as a result, they have valuable use in high-performance applications, such as industrial cutting tools for milling and grinding metals.

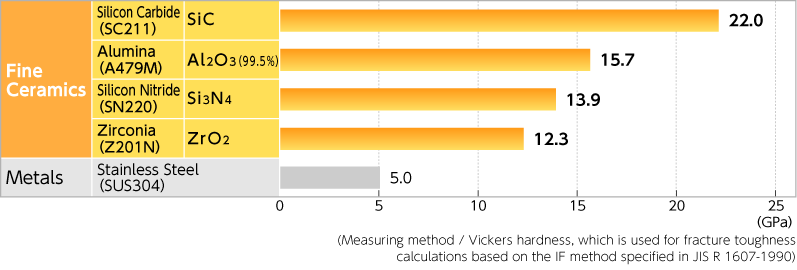

A material's hardness is determined by measuring the size of an indentation made by a sharp diamond pressed strongly onto a material specimen. The hardness of alumina ceramics is nearly three times that of stainless steel; silicon carbide is more than four times harder than stainless steel. This extreme hardness is one of many unique properties that makes Fine Ceramics "super materials" for modern technology.

Watch this video to learn about the unique Hardness of Fine Ceramics

Applications: Cutting tools and bearings.

Description

Hardness

The hardness of Fine Ceramics is generally indicated using a Vickers hardness number. The method for measuring the hardness of Fine Ceramics is defined in JIS R 1610 (ISO 14705: 2000). Vickers hardness is a resistance value obtained by pressing a diamond indenter onto a test specimen.

Extreme hardness is the primary feature that endows Fine Ceramics with their superior wear resistance. This has led to the use of Fine Ceramics in a wide range of applications, including pump components, cutting tools, seal rings, bearings and a multitude of wear-resistant components for industrial equipment.

Vickers Hardness

For more information, please see Excerpt of Graph Values.

Wear Resistance

Fine Ceramics that exhibit excellent hardness also greatly surpass most metals in wear resistance. During wear resistance tests, small glass beads were continuously sprayed at high speeds onto Fine Ceramics and metals for extended periods of time. The Fine Ceramics displayed only about 10 percent of the abrasion observed in the stainless steel samples. Additionally, during a test in which disks with Fine Ceramics and metals attached were continuously rotated in wet sand for eight hours, the Fine Ceramics displayed considerably less abrasion.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Strength (2)

Strength (2)

Rigidity—Less Elastic Deformation Compared to Metals

Rigidity—Less Elastic Deformation Compared to Metals

Characteristics of Fine Ceramics

Strength (3)

Strength (3)

Toughness—Highly Resistant to Fracturing

Toughness—Highly Resistant to Fracturing

Characteristics of Fine Ceramics

Strength (4)

Strength (4)

Specific Gravity (Density) to Provide Strength and Lightweight Properties

Specific Gravity (Density) to Provide Strength and Lightweight Properties

Characteristics of Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

Decorative Fine Ceramics

Decorative Fine Ceramics

Designed to Express Deep Color and Luster

Designed to Express Deep Color and Luster

Learning about Fine Ceramics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance