Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

How to Make a Fine Ceramic Knife

Advanced Technologies Produce Fine Ceramic Knives with a Razor-Sharp Edge

Granulated powder is filled into a knife-shaped mold and fired.

How to Make a Fine Ceramic Knife

-

Water, raw powder and ceramic milling balls are fed into a mixer-like device called a mill.

-

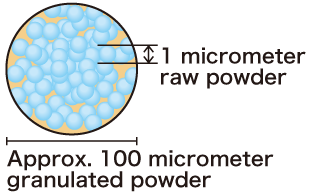

To create particles of uniform size, with diameters of approximately one micrometer (1 µm or 0.001 mm), raw materials are first mixed into a slurry — a fluid of water and ceramic powder in which the particles are blended.

-

A spray dryer dehydrates the raw materials in the slurry to make a granulated powder.

-

The granulated powder is used to fill a knife-shaped mold.

-

The mold is placed under high pressure — 1 ton per cm2 (approx. 12,900 psi) — to solidify the powder into the desired shape.

-

The material is then fired and sintered in a kiln, like conventional ceramics, but under precisely controlled temperatures.

-

During the firing process, the ceramic blade shrinks to 75 percent of its original, unfired size, while the volume shrinks by nearly half. These shrinkage rates are carefully calculated during the design process, so the finished size matches the design specifications.

-

The blade is then ground with a diamond wheel to produce a razor-sharp edge.

-

A handle is then attached to complete the process.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Fine Ceramics Production Process

Fine Ceramics Production Process

A Series of Complex Production Processes Are Used to Make Fine Ceramic Products

A Series of Complex Production Processes Are Used to Make Fine Ceramic Products

Introduction to Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

What Makes Fine Ceramics Knives so Special?

What Makes Fine Ceramics Knives so Special?

Four Advantages that Metals Cannot Offer

Four Advantages that Metals Cannot Offer

Learning about Fine Ceramics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance