Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

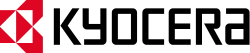

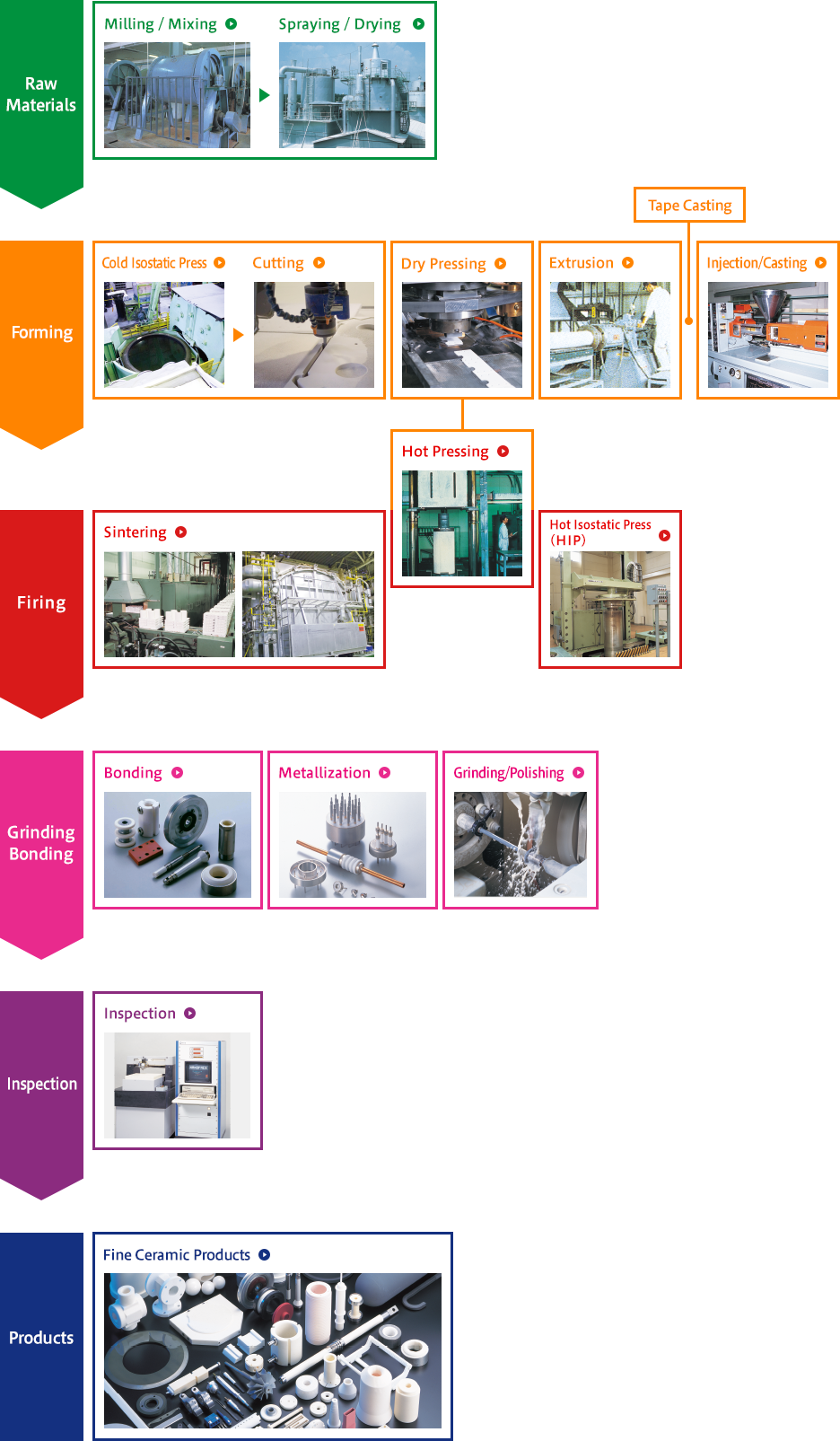

Fine Ceramics Production Process

A Series of Complex Production Processes Are Used to Make Fine Ceramic Products

Precisely controlled raw materials are converted into products with exceptional functional characteristics.

The raw materials used in making Fine Ceramics (also known as "advanced ceramics") include inorganic solid powders with precisely controlled purity, particle size and distribution. These raw materials are formulated for specific properties and functionality, then mixed with a binding agent or binder. Afterward, they are shaped and cut to precise requirements and fired at extreme heat in temperature-controlled kilns.

Firing removes the moisture and binders. With additional firing, powder particles are sintered together and the products shrink due to reduced porosity. This process results in products of extreme density and hardness.

Fine Ceramic Production Process (example)

Click on photos for details.

Click on photos for details.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Fine Ceramics Use Highly Purified Raw Materials

Fine Ceramics Use Highly Purified Raw Materials

Raw Materials Need to Meet Demanding Performance Requirements

Raw Materials Need to Meet Demanding Performance Requirements

Introduction to Fine Ceramics

How to Make a Fine Ceramic Knife

How to Make a Fine Ceramic Knife

Advanced Technologies Produce Fine Ceramic Knives with a Razor-Sharp Edge

Advanced Technologies Produce Fine Ceramic Knives with a Razor-Sharp Edge

Introduction to Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

Characteristics of Fine Ceramics

Characteristics of Fine Ceramics

Supporting Our Lives From Behind the Scenes

Supporting Our Lives From Behind the Scenes

Characteristics of Fine Ceramics

Milling / Mixing

Raw material milling and mixing are important processes in the production of Fine Ceramics (also known as "advanced ceramics") that determine the material properties, quality and stability of finished products.

Raw material milling and mixing are important processes in the production of Fine Ceramics (also known as "advanced ceramics") that determine the material properties, quality and stability of finished products.

Raw powder and solvating media (such as water) are fed into a mill with ceramic balls. This ball mill is then rotated or shaken to create a uniform mixture (called a slurry), with evenly distributed particles of various sizes.

Adjustments are made by adding raw powder and binder dispersants throughout this process.

Spraying / Drying

A slurry adjusted through raw material milling and mixing is sprayed and dried in a hot-air spray dryer to form a granulated powder of spherical bodies. Enhancing the spherical composition of the raw material helps facilitate the next process: filling the forming dies.

Cold Isostatic Press

Raw material powders poured into a rubber mold are formed in a high-pressure container by adding hydraulic pressure.

Dry Pressing

This forming method involves filling a die with dried and granulated raw materials, and pressing them into a shape close to that of the finished product.

Granulated raw materials fill a metallic mold, and pressure is applied from the top and bottom (uniaxial press) to achieve highly dense compaction. This method is ideal for mass-producing semi-complex machinery parts which require high levels of dimensional accuracy.

Extrusion

This is a forming method in which dried and granulated raw materials are mixed with water, binder, a plasticizing agent and a dispersing agent. The resulting clay-like, plastic body is then extruded into the desired shape under pressure.

This method is ideal for long products with continuous and unchanging cross-sections.

Injection / Casting

This is a forming method in which dried and granulated raw materials are mixed with additives to provide a degree of fluidity. The raw material is then pressure-filled into a forming die that gives it a shape close to that of the finished product.

In the injection molding process, raw materials are mixed with resin in order to provide the necessary degree of fluidity, and then injected into the molding die. The mold is then cooled to harden the binder and produce a "green" compact part (also known as an unsintered powder compact).

In the casting process, mixed raw materials are combined with solvating media and a dispersant, and then fed into an absorbent die. The materials are then dehydrated and solidified to make a compact.

Both methods are suitable for complex, three-dimensionally shaped products requiring high levels of dimensional accuracy.

Injection Molding

Cutting

Because ceramics are very hard, cutting them after they have been sintered requires considerable energy and specialized tools such as diamond wheels. Considering this, engineers strive to cut or process ceramics into a shape as close to the finished shape as possible before sintering, which involves estimating the degree of shrinkage that will take place during the sintering process. Super hard tools and drills are used in this process.

Hot Pressing

This forming method involves applying pressure at high temperatures in order to reduce porosity (voids) and produce dense sintered bodies.

A carbon mold is filled with raw powder, which is then heated and pressurized simultaneously from the top and bottom to make a sintered body. This method yields ceramic bodies of simple shapes.

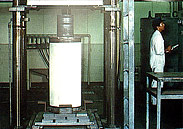

Sintering

In the firing process, raw materials that are compression-molded (volumetric filling rate: approx. 60%) are heated at temperatures below their melting points to sinter powder and create density. Ceramic powder particles induce mass transfer at high temperatures through contact points between particles, combining in a manner similar to water droplets. Depending on the intended application, a variety of sintering methods may be used — such as vacuum sintering, atmosphere sintering and sintering in non-oxidizing atmospheres.

Hot Isostatic Press (HIP)

In this process, gas pressure is applied isostatically at high temperatures to enhance sintering and produce dense bodies. After materials are pre-sintered, and their density is increased to almost 95 percent of the theoretical density, they are placed in a pressure container equipped with a furnace. Gas pressure is then applied isostatically at 1,000 to 2,000 atmospheres while being heated.

Grinding / Polishing

This important process is designed to fabricate products with high levels of dimensional accuracy and mirror-finished surfaces. It is generally performed using a diamond wheel.

Because ceramics are extremely hard, it is necessary to use diamond — the hardest material in the world — for the grinding and polishing process.

Metallization

Metallization refers to the process of affixing a metallic layer to the surface of a sintered body to form conductive patterns or provide hermetic sealing.

One method involves coating the ceramic surface with a paste containing metallic powder, and then applying high temperatures to burn this metallic layer onto the surface of the ceramic. A related method involves applying metallic layers through an electroplating process.

Bonding

This is an important and value-adding process for joining multiple ceramic products, or joining ceramic products to metallic or resin materials.

Several methods may be employed to combine these items, including mechanical joining or other processes using adhesives, glass or wax.

Inspection

Products are delivered after rigorous inspection. This inspection ensures that all products are tested to perform at the highest level and allows customers to use them with confidence.

Fine Ceramic Products

Behind the scenes, Fine Ceramics (also known as "advanced ceramics") play some of the most important roles in our daily lives.

Tape Casting

This method is used to produce continuous thin compacts using slurries composed of raw powder, binder and solvating media.

The tape casting process generally employs a "doctor blade" to spread the slurry into a thin film. This process is ideal for preparing the "green" (unfired ceramic) tape used in manufacturing multilayer ceramic integrated circuit packages and ceramic chip capacitors.

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance