Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Fine Ceramics Use Highly Purified Raw Materials

Raw Materials Need to Meet Demanding Performance Requirements

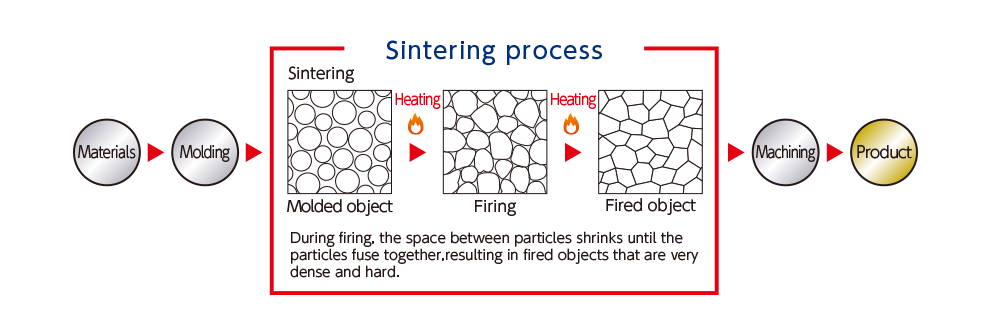

Inorganic solid powders are converted into products with extreme density and hardness.

Fine ceramics are made from inorganic solid powders with precisely controlled properties of purity, particle size and particle distribution. The process involves mixing different powders together to produce a ceramic with specific material characteristics. This powdered mixture is blended with a binder so it can be molded to precise specifications, machined in a "raw" state, and then fired in a controlled furnace.

Firing, also called sintering, involves heating the raw ceramic to a temperature below the melting point. This eliminates the moisture and binder, shrinking the microscopic gaps between particles and fusing them together to form fine ceramic products of extreme hardness and density.

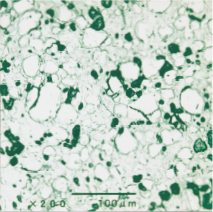

Fired object – Transmission electron micrograph

Fine Ceramics

Lead zirconate titanate Pb (Zr, Ti) O3

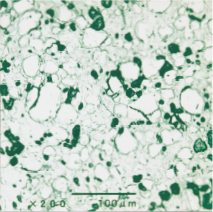

Fired object (Pb [Zr, Ti] O3) – Transmission electron micrograph

A lamellar domain, oriented in multiple directions within one particle.

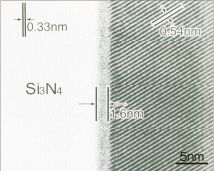

Silicon nitride Si3N4

Fired silicon nitride – High-resolution photograph

An amorphous phase is observed along the interface between silicon nitride particles and a crystalline grain boundary phase.

Ceramics

Porosities of ceramic

Crystalline structure of ceramic

Porosities of ceramic

Crystalline structure of ceramic

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Fine Ceramics Production Process

Fine Ceramics Production Process

A Series of Complex Production Processes Are Used to Make Fine Ceramic Products

A Series of Complex Production Processes Are Used to Make Fine Ceramic Products

Introduction to Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

Four-Frame "Manga" Comics

Four-Frame "Manga" Comics

Easy to Watch, Touch and Understand Fine Ceramics

Easy to Watch, Touch and Understand Fine Ceramics

Four-Frame "Manga" Comics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance