Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Strength (3)

Toughness—Highly Resistant to Fracturing

Typically, ceramics are characterized by hardness as well as a lack of toughness.

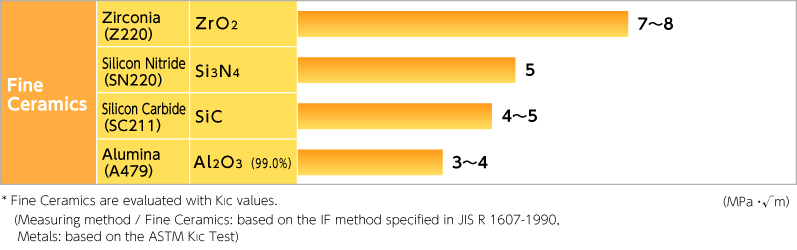

The toughness of a material is measured by its resistance to fracturing. Among Fine Ceramics (also known as "advanced ceramics"), zirconia possesses relatively high levels of toughness. As a result, it is used for products such as blades, scissors and knives.

Applications: Knives, scissors and other related products.

Description

Toughness

Fracture toughness measures a fissured material's resistance to fracturing (whether the fissures exist throughout the material or only on its surface).

The fracture toughness of Fine Ceramics is measured using the critical stress intensity factor KIC at crack terminations where fracturing generally occurs. In particular, the fracture toughness KIC value is used to compare material's shape when a fissure is opened by a plane deformation. Though Fine Ceramics generally possess low fracture toughness, partially-stabilized zirconia, used for products such as scissors and knives, offers significant fracture-toughness improvements.

Fracture Toughness

For more information, please see Excerpt of Graph Values.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Strength (1)

Strength (1)

Extreme Hardness Surpassing that of Metals

Extreme Hardness Surpassing that of Metals

Characteristics of Fine Ceramics

Strength (2)

Strength (2)

Rigidity—Less Elastic Deformation Compared to Metals

Rigidity—Less Elastic Deformation Compared to Metals

Characteristics of Fine Ceramics

Strength (4)

Strength (4)

Specific Gravity (Density) to Provide Strength and Lightweight Properties

Specific Gravity (Density) to Provide Strength and Lightweight Properties

Characteristics of Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance