Challenge to Solve: How to Select the Best Board-Mounting Option for Your Needs

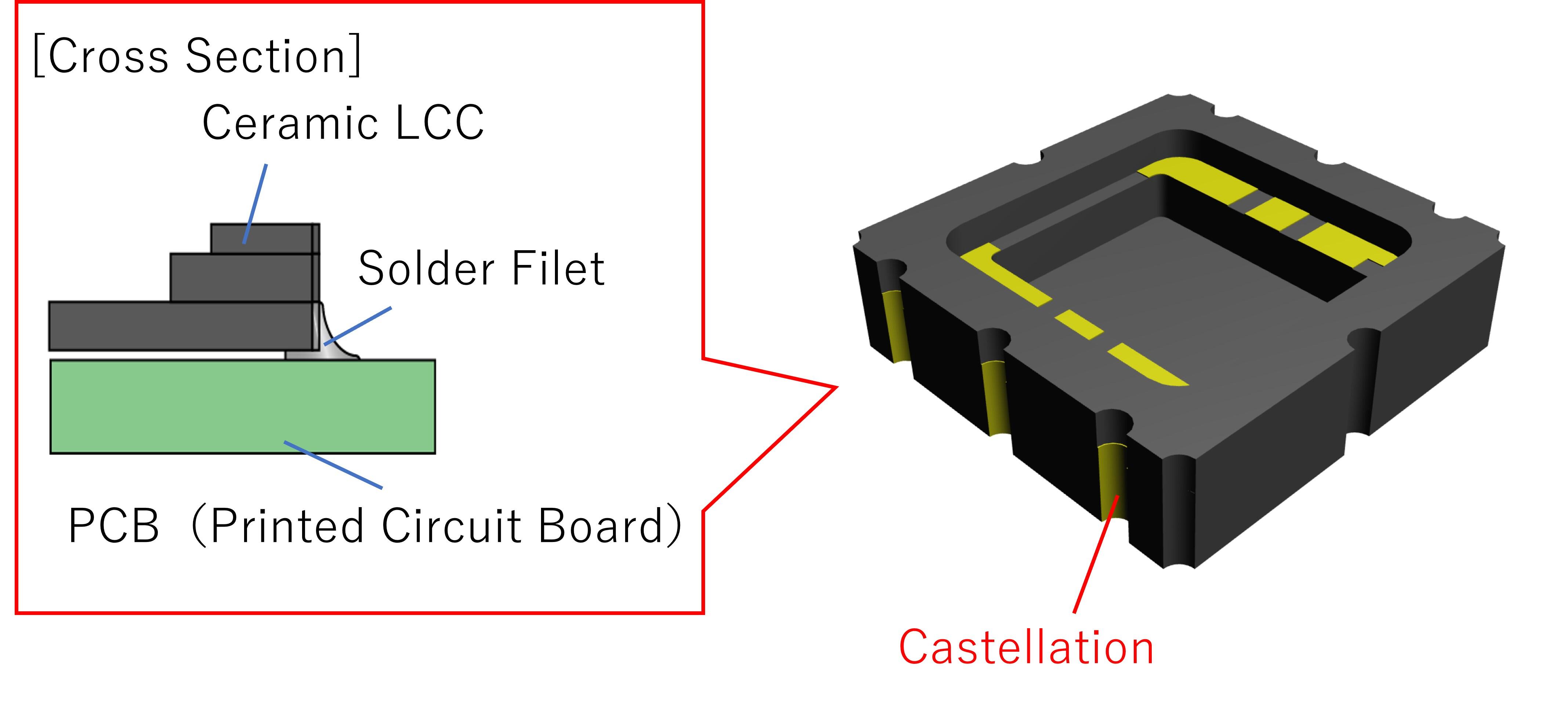

Mounting packaged devices onto PCBs ("board-level assembly") involves various options that are determined by device specifications, including size, reliability requirements, and others. Ceramic packages allow optimal board-mounting options due to their unique material characteristics, which offer design flexibility and allow bonding with different materials, including metal brazing. Ceramic Leadless Chip Carrier (LCC) packages offer additional options using side castellations. By metallizing the castellations, solder fillets can be formed during the attachment process for enhanced board-level assembly reliability.

* Castellation: A notch cut at the side of an LCC to improve solder mount reliability by forming solder fillets (see below).

Board-Level Assembly Options

Insertion Mount

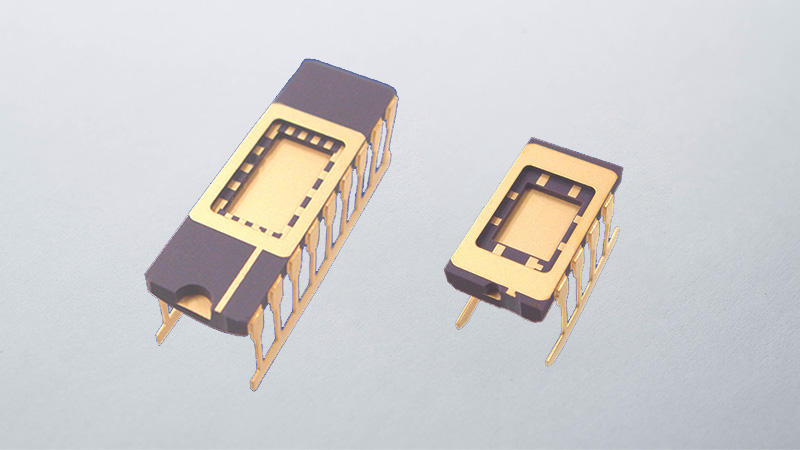

C-DIP

(Ceramic Dual Inline Packages)

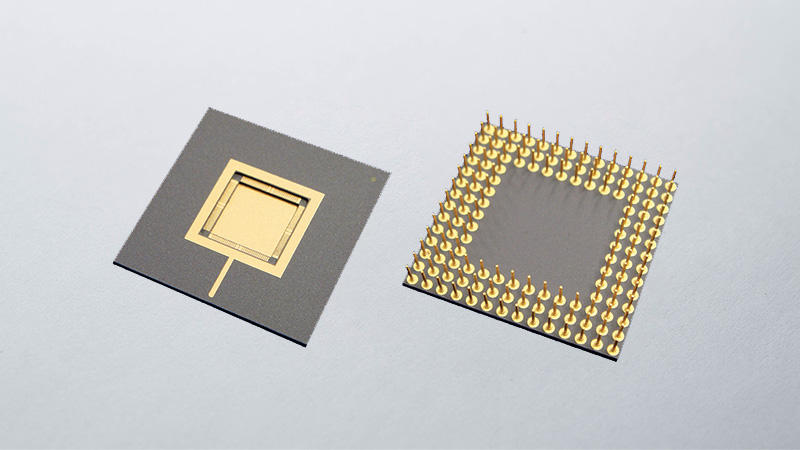

C-PGA

(Ceramic Pin Grid Array Packages)

Surface Mount

Leaded

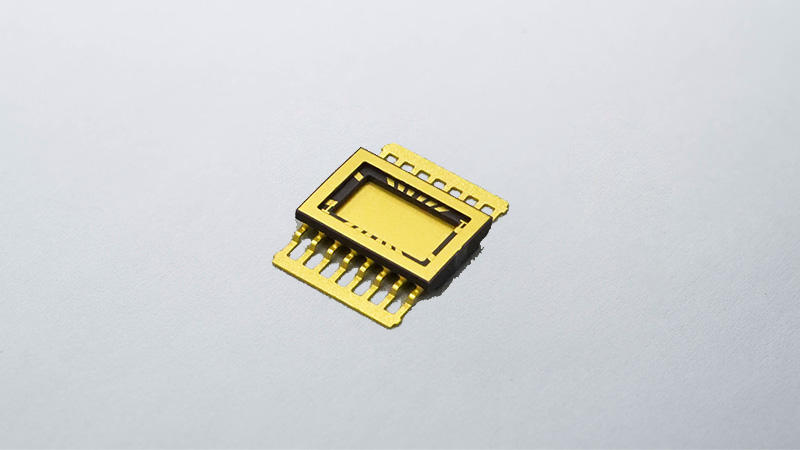

C-SOP

(Ceramic Small Outline Packages)

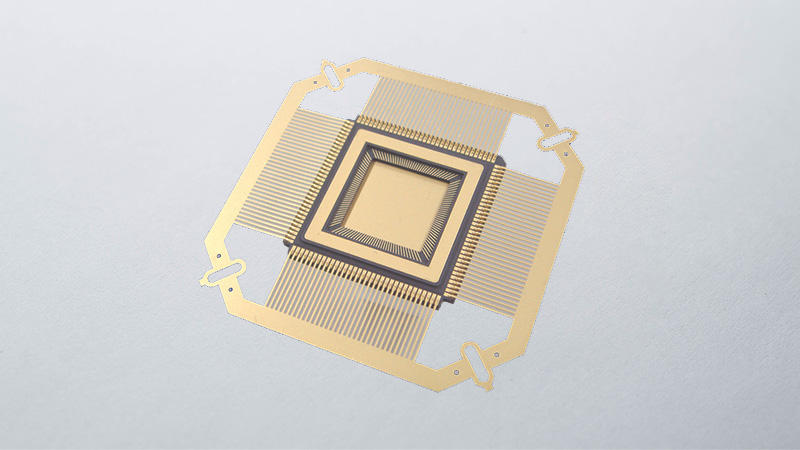

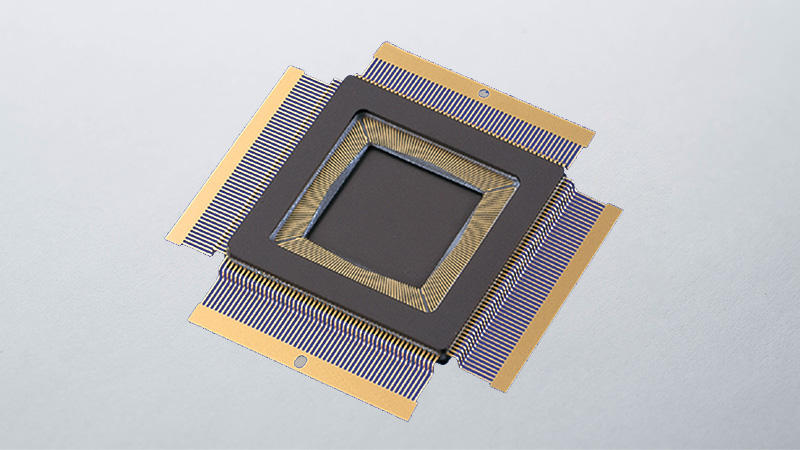

C-QFP

(Ceramic Quad Flat Packages)

CERQUAD® Packages

* "CERQUAD" is a registered trademark of Kyocera Corporation in Japan

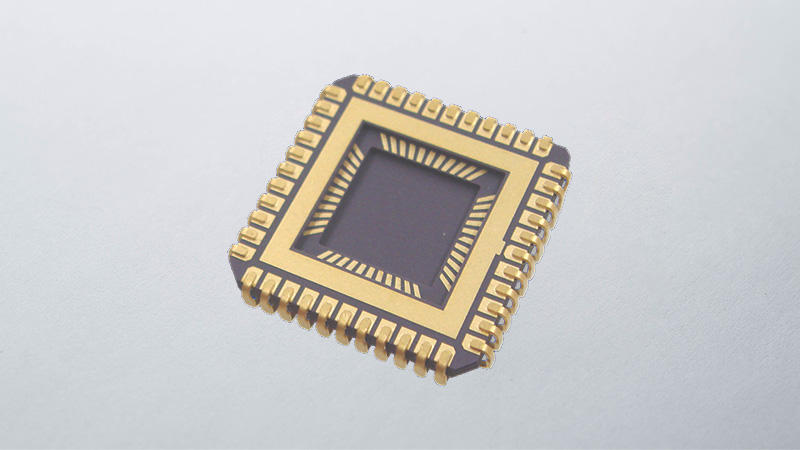

C-QFJ

(Ceramic Quad Flat J-Leaded Packages)

Flat Packages

Leadless

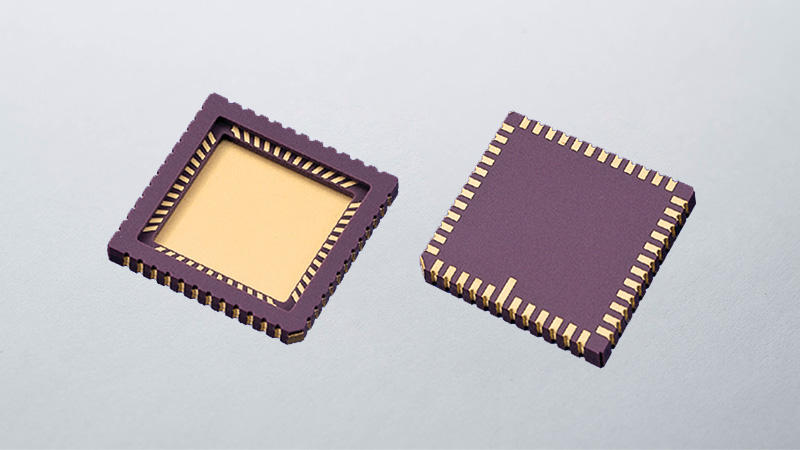

C-QFN

(Ceramic Quad Flat Non-Leaded Packages)

SMD (Surface Mount Device) Packages

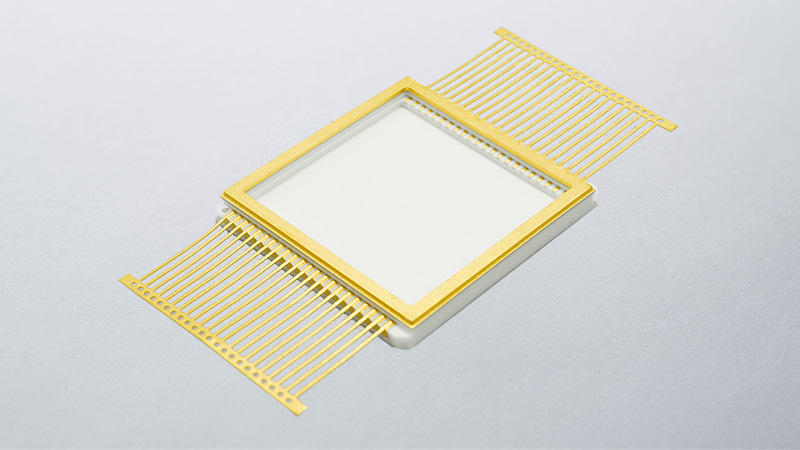

Castellations on LCCs (Leadless Chip Carriers)

LCC packages offer additional assembly options using "side castellations." Metallizing the castellation allows a fillet to be formed during the solder-attachment process, providing the following advantages:

1. Increased package-to-board solder joint strength

2. Easy visual inspection of solder joint condition