Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Heat (1)

Heat Resistance to Withstand Extreme Temperatures

Conventional ceramics, including bricks and tiles, are well known for their ability to withstand high temperatures. Nonetheless, Fine Ceramics (also known as "advanced ceramics") are more heat resistant than these materials by far. While aluminum begins to melt at approximately 660℃ (approx. 1,220℉), alumina Fine Ceramics only begin to melt or decompose at temperatures above 2,000℃ (approx. 3,632℉).

Watch this video to learn about the Heat Resistant properties of Fine Ceramics

Applications: Engine components and foundry / smelting components.

Description

Heat and Thermal Shock Resistance

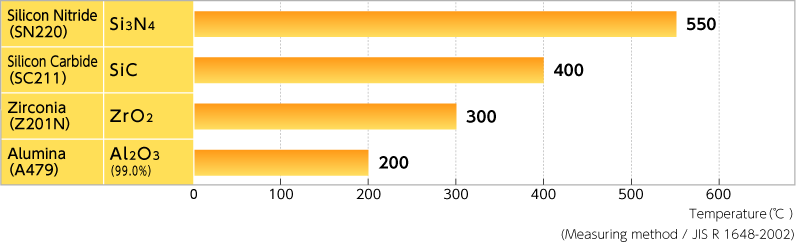

The heat resistant properties of Fine Ceramics are measured by the temperatures at which they begin to melt, and by their levels of thermal shock resistance. Thermal shock resistance refers to a material's ability to withstand rapid changes in temperature. Silicon nitride, a particularly heat tolerant material, displays superior resistance to thermal shock, as tested by heating the material to 550℃ (1,022℉) and then rapidly cooling it by dropping it into water. Silicon nitride is thus suitable for applications involving extreme temperature variations, and in high-temperature industries such as metal manufacturing and energy generation.

Thermal Shock Resistance (Water Immersion Test)

For more information, please see Excerpt of Graph Values.

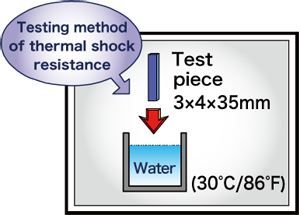

Testing Thermal Shock Resistance

A material's thermal shock resistance is determined by the difference between the peak temperature of the Fine Ceramic which was heated, rapidly cooled, and then fractured, and that of the cooling media. Stresses are generated by temperature differences between the interior and surface of a test piece, which occur during rapid cooling. When these stresses exceed the strength of the Fine Ceramic, fracturing occurs. These temperature differences are determined by the thermal conductivity of ceramics, as well as the coefficient of heat transfer between the Fine Ceramic and the cooling media. In addition, the stresses generated are determined by multiplying Young's modulus, the coefficient of thermal expansion, and the temperature differences between the interior and surface of the Fine Ceramic.

Watch this video to learn about the Thermal Shock resistant properties of Fine Ceramics

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Heat (2)

Heat (2)

Low Thermal Expansion

Low Thermal Expansion

Characteristics of Fine Ceramics

Heat (3)

Heat (3)

Thermal Conductivity Easily Transmits Heat

Thermal Conductivity Easily Transmits Heat

Characteristics of Fine Ceramics

Different Types of Fine Ceramics

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Wide Variety of Products to Support both Industry and Society

Introduction to Fine Ceramics

Fine Ceramics Contribute to a Cleaner Environment

Fine Ceramics Contribute to a Cleaner Environment

Ideal for an Eco-Friendly Life with Higher Power Generation Efficiency

Ideal for an Eco-Friendly Life with Higher Power Generation Efficiency

Learning about Fine Ceramics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance