Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Ceramics vs. Fine Ceramics

Big Differences in Raw Materials and Production Processing

Ceramics are made from natural minerals; Fine Ceramics are made from highly refined raw materials.

Ceramic materials exhibit hardness, excellent heat and corrosion resistance, and electrical insulation properties. Typical examples include china, firebricks, cements and glass.

In addition to these properties, Fine Ceramics (also known as "advanced ceramics") have many advanced mechanical, electrical, electronic, magnetic, optical, chemical and biochemical characteristics. Today, Fine Ceramics have many roles in fields such as semiconductors, automobiles, telecommunications, industrial machinery and healthcare.

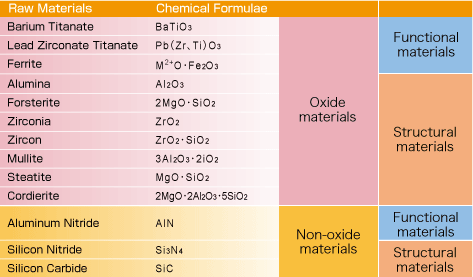

The physical differences between ceramics and Fine Ceramics mainly arise from their raw materials and manufacturing processes. Ceramics are manufactured by mixing, shaping and firing natural minerals including pottery stones, feldspar and clay. In contrast, Fine Ceramics are manufactured using highly purified natural raw materials, artificial raw materials synthesized through chemical processes and other non-naturally occurring compounds. Through a series of precisely controlled, complex processes such as forming, machining, firing and grinding, these compounded raw materials turn into high-value-added products with excellent dimensional accuracy and functional characteristics.

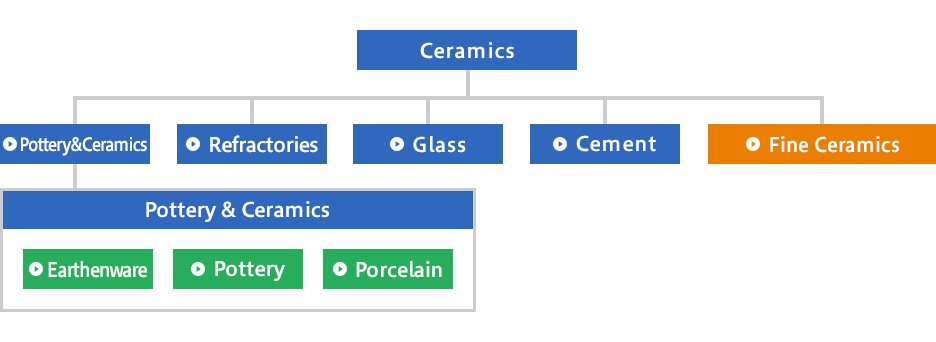

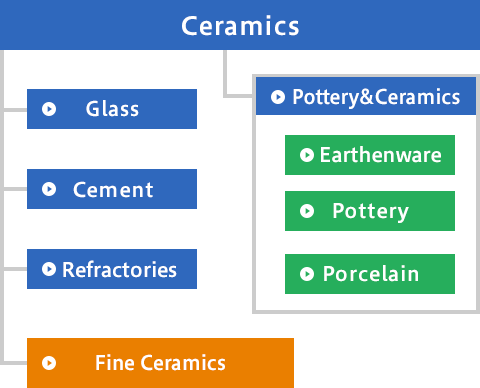

Classification of Ceramics

Click item for details (below).

Click item for details (below).

Pottery & Ceramics

Pottery and ceramics are made by forming and firing raw materials including clay and pottery stones. They are divided into several categories, such as earthenware and porcelain, depending on such factors as raw material composition, firing temperatures and water absorption. Fine Ceramics are primarily composed of unique minerals such as alumina porcelain.

Earthenware

Includes clay biscuit vessels that are kneaded, shaped and fired at low temperatures (approx. 800℃ / 1,472℉). Typical examples include wares from Japan's Jomon Period (14,000 – 400 B.C.) and Yayoi Period (500 B.C. – 300 A.D.), as well as archaeological artifacts from the Middle East dating from around 6000 B.C. Modern uses include terracotta flowerpots, red bricks, stoves and water filters.

Pottery

Includes glazed ceramics fired at higher temperatures than earthenware (1,000 – 1,250℃ / 1,832 – 2,282℉), but which possess water absorption properties. Sue ware, Raku ware, Maiolica and Delftware are included in this family. Used in many modern products such as tea sets, tableware, vases and roof tiles.

Porcelain

Includes colorfully glazed, white ceramics hardened by forming and firing mixtures of high-purity clays (or pottery stones), silicas and feldspars. They were developed during China's Sui and Tang Dynasties (600 – 700 A.D.) and adopted worldwide. This family includes Jingdezhen ware, Arita ware and Seto ware. Widely used in modern tableware, insulators, arts & craftworks and exterior tiles.

Ceramics

Refractories

Able to withstand high temperatures: used in the construction of kilns for making iron, steel and glass.

Glass

Amorphous substance made by fusing and forming minerals such as silica, limestone and soda ash.

Cement

Fine powder made by mixing, firing and grinding minerals such as limestone and silica, which bind stone and sand through hydration to make concrete.

Fine Ceramics

Engineered materials with chemical compositions that are precisely adjusted using refined or synthesized raw powders and well-controlled methods of forming, sintering and processing. With higher levels of functionality compared to conventional ceramics, they are widely used in fields such as semiconductors, automobiles and industrial machinery. Fine Ceramics are also called new ceramics or advanced ceramics.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

What are Fine Ceramics?

What are Fine Ceramics?

Term Coined by the Founder of Kyocera

Term Coined by the Founder of Kyocera

Introduction to Fine Ceramics

Fine Ceramics Use Highly Purified Raw Materials

Fine Ceramics Use Highly Purified Raw Materials

Raw Materials Need to Meet Demanding Performance Requirements

Raw Materials Need to Meet Demanding Performance Requirements

Introduction to Fine Ceramics

History of Fine Ceramics

History of Fine Ceramics

Rooted in Jomon Ware Used Over 10,000 Years Ago

Rooted in Jomon Ware Used Over 10,000 Years Ago

Introduction to Fine Ceramics

Four-Frame "Manga" Comics

Four-Frame "Manga" Comics

Easy to Watch, Touch and Understand Fine Ceramics

Easy to Watch, Touch and Understand Fine Ceramics

Four-Frame "Manga" Comics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance