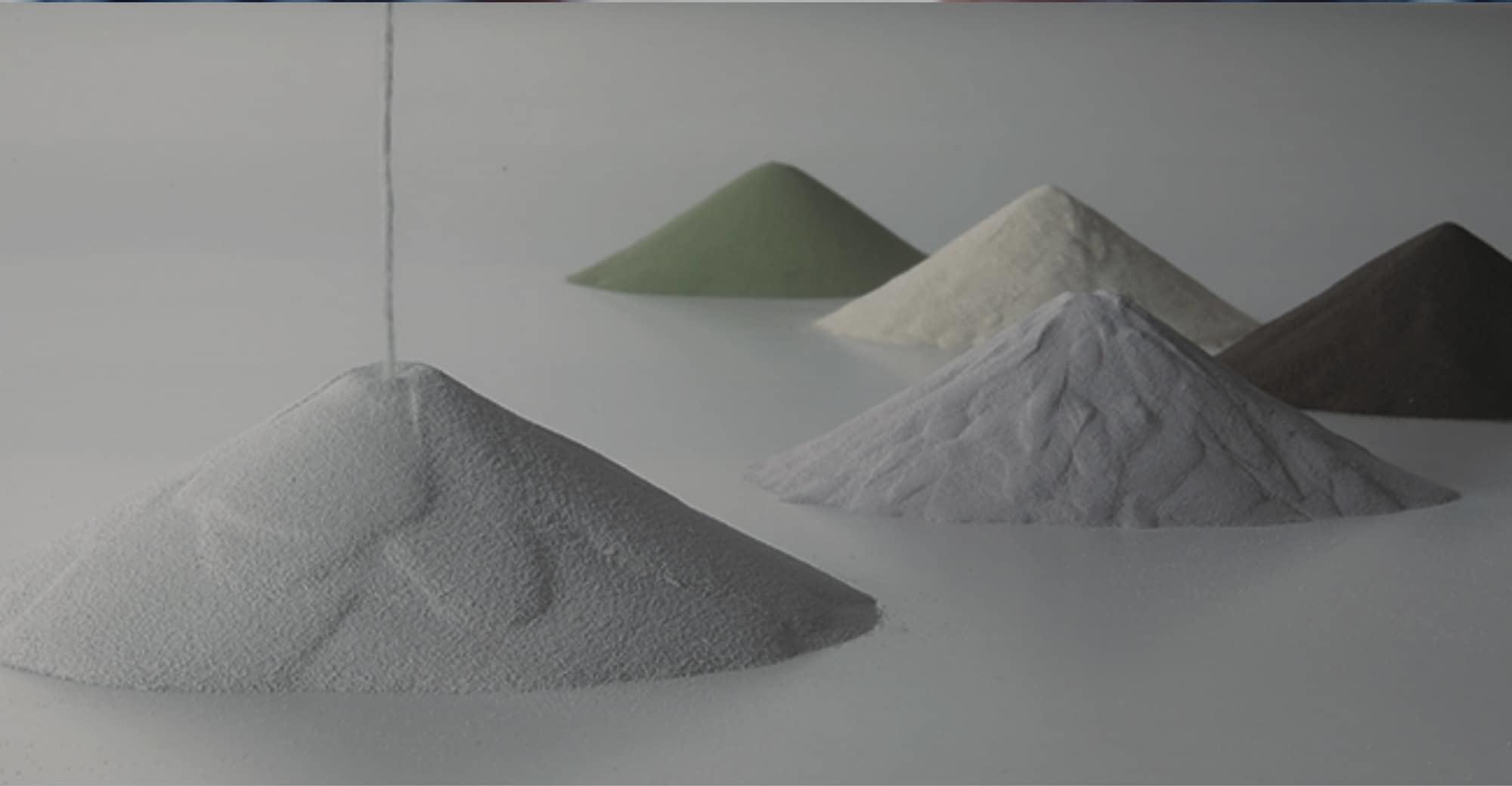

Silicon Carbide (SiC)

Silicon Carbide is one of the hardest Fine Ceramic materials and exhibits high chemical resistance. In particular, solid-phase sintered silicon carbide is an excellent heat-resistant material that retains its strength even at 1400°C. Moreover, its superior sliding properties make it suitable for applications such as mechanical seals and pump parts, while its high thermal conductivity and electrical semiconductivity render it ideal for semiconductor processing equipment and general industrial machine parts.

- Important property :

- Chemical Resistance

- High Strength

- Semiconductive

Features

-

Silicon Carbide is one of the hardest Fine Ceramic materials and exhibits high chemical resistance.Silicon carbide has high hardness and corrosion reisistance due to its chemical and physical stability.

-

Excellent high temperature strengthSilicon carbide maintains its strength even at temperatures up to 1400°C.

-

Notable features of this material are extremely high thermal conductivity and electrical semiconductivityCompared to other ceramics, it has extremely high thermal conductivity and is semiconductive.

Shape

Dimensional precision achieved by machining

When dimensional precision is required for machined ceramics, Kyocera is capable of achieving the tolerances as shown in the table below. If greater tolerances are required, please consult us.

MACHINING DIMENSIONAL PRECISION

(Data are in mm unless otherwise specified)

PRECISION MACHINED PRODUCTS

Ultra-precision is possible with Kyocera's unique techniques. Precision machining is affected by shape and material. Some practical examples are shown in the table below.

Property

Product examples

-

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.

Heat Dissipation Structure Ceramic SubstratesMonolithic ceramic structure with no bonding material for long-term reliability.- Design flexibility

- High-Temperature Durability

-

Heat Exchanger Tubes for Garbage IncineratorsLong life SiC heat exchanger tubes provide superior thermal conductivity.

Heat Exchanger Tubes for Garbage IncineratorsLong life SiC heat exchanger tubes provide superior thermal conductivity.- Heat Resistance

- High Thermal Conductivity

-

Faucets, ValvesCeramic faucet valves with superior wear resistance and sealing performance.

Faucets, ValvesCeramic faucet valves with superior wear resistance and sealing performance.- Wear Resistance

- Chemical Resistance

-

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.

Handling ArmsHeat-resistant, non-damaging handling arms provide high functionality.- Heat Resistance

-

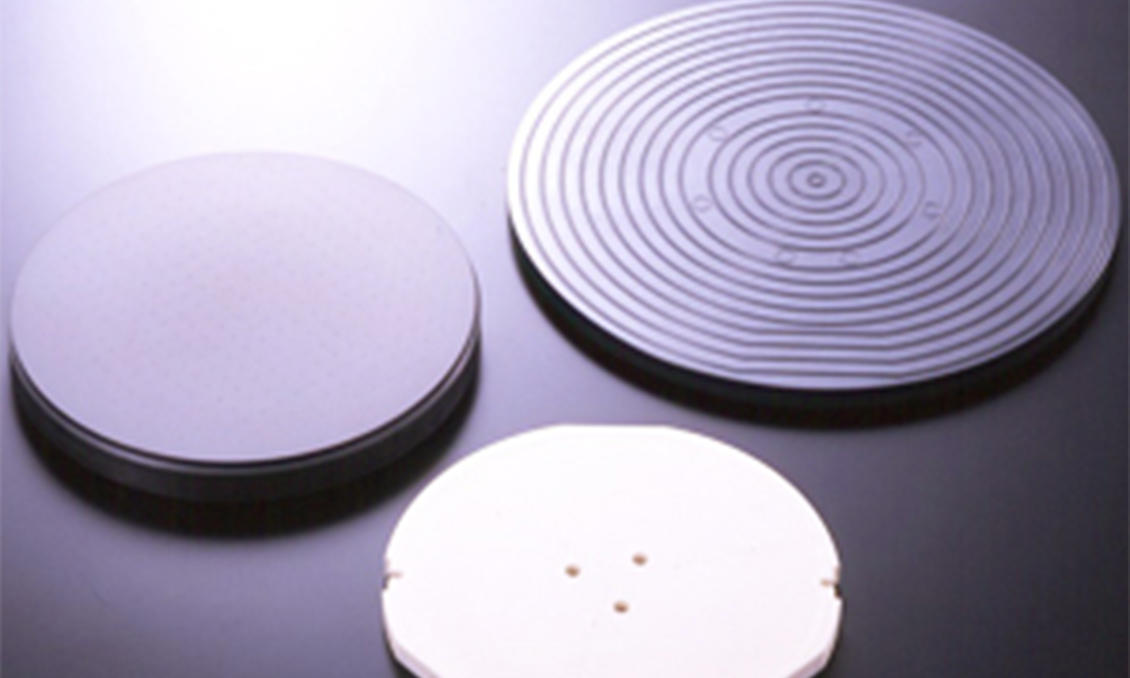

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.

Vacuum Chucks, Integrated Mirrors for Stages, Stage PartsHigh-precision vacuum chucks with various surface profiles/patterns for diverse operating conditions.- High Stiffness

- High-Precision

-

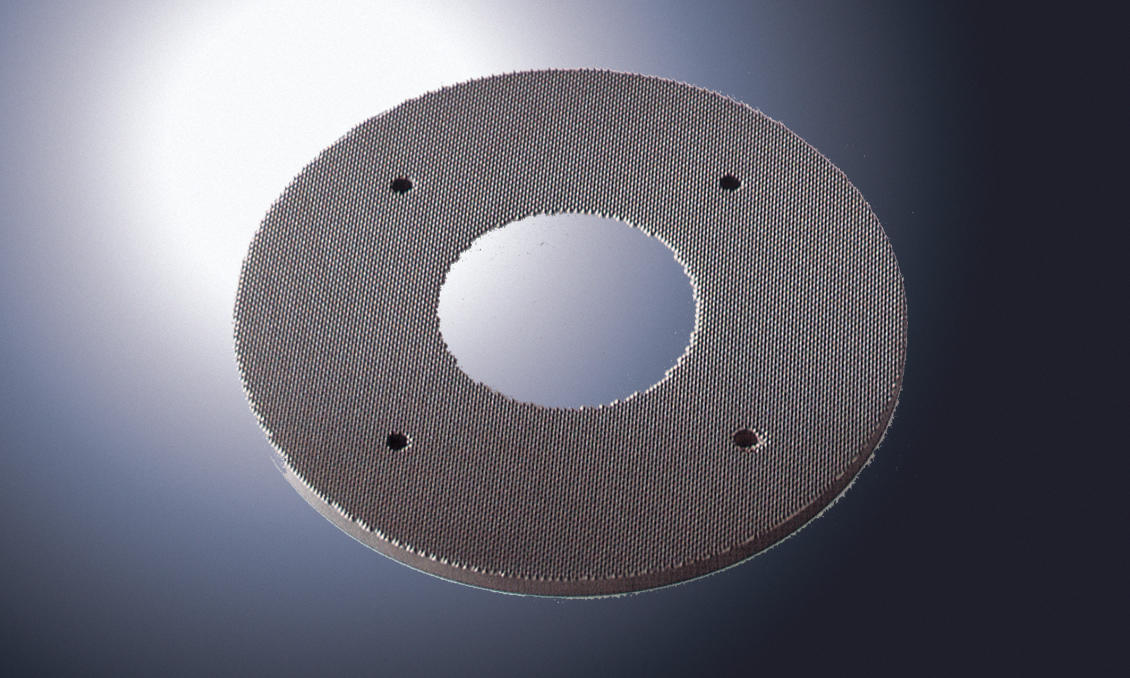

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.

Dressing Plates for Polishing PadsDLC coating improves the lifetime of dressing tools.- Durability

-

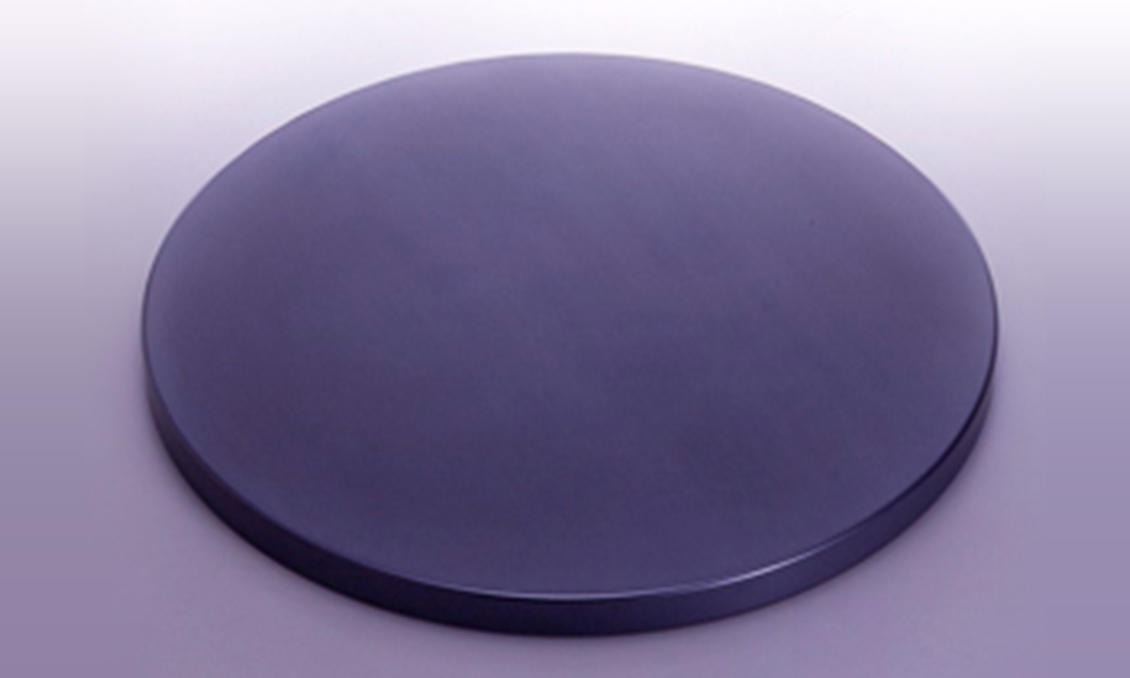

SiC (Silicon Carbide) Polishing PlatesLess deformation through lower thermal distribution. Stronger chemical resistance. A range of surface profiles are available.

SiC (Silicon Carbide) Polishing PlatesLess deformation through lower thermal distribution. Stronger chemical resistance. A range of surface profiles are available.- High Young's Modulus

- Low Thermal Expansion

- AluminaAl2O3

- Single-Crystal SapphireAl2O3

- ZirconiaZrO2

- Silicon NitrideSi3N4

- Silicon CarbideSiC

- Zirconia Toughened AluminaZTA

- Cordierite2MgO・2Al2O3・5SiO2

- CermetTiC,TiN

- YttriaY2O3

- Single-Crystal YAGY3Al5O12

- YAG-dispersed AluminaAl2O3

- Aluminum NitrideAlN

- Silicon-Infiltrated Silicon CarbideSiSiC

- Porous Ceramics

Customizable