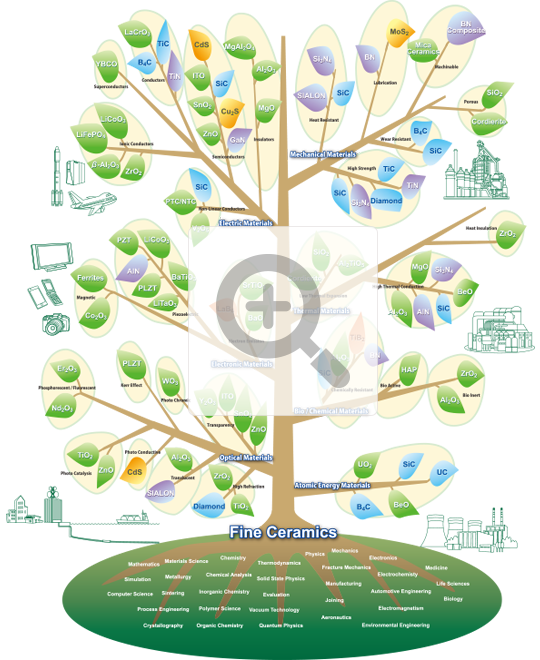

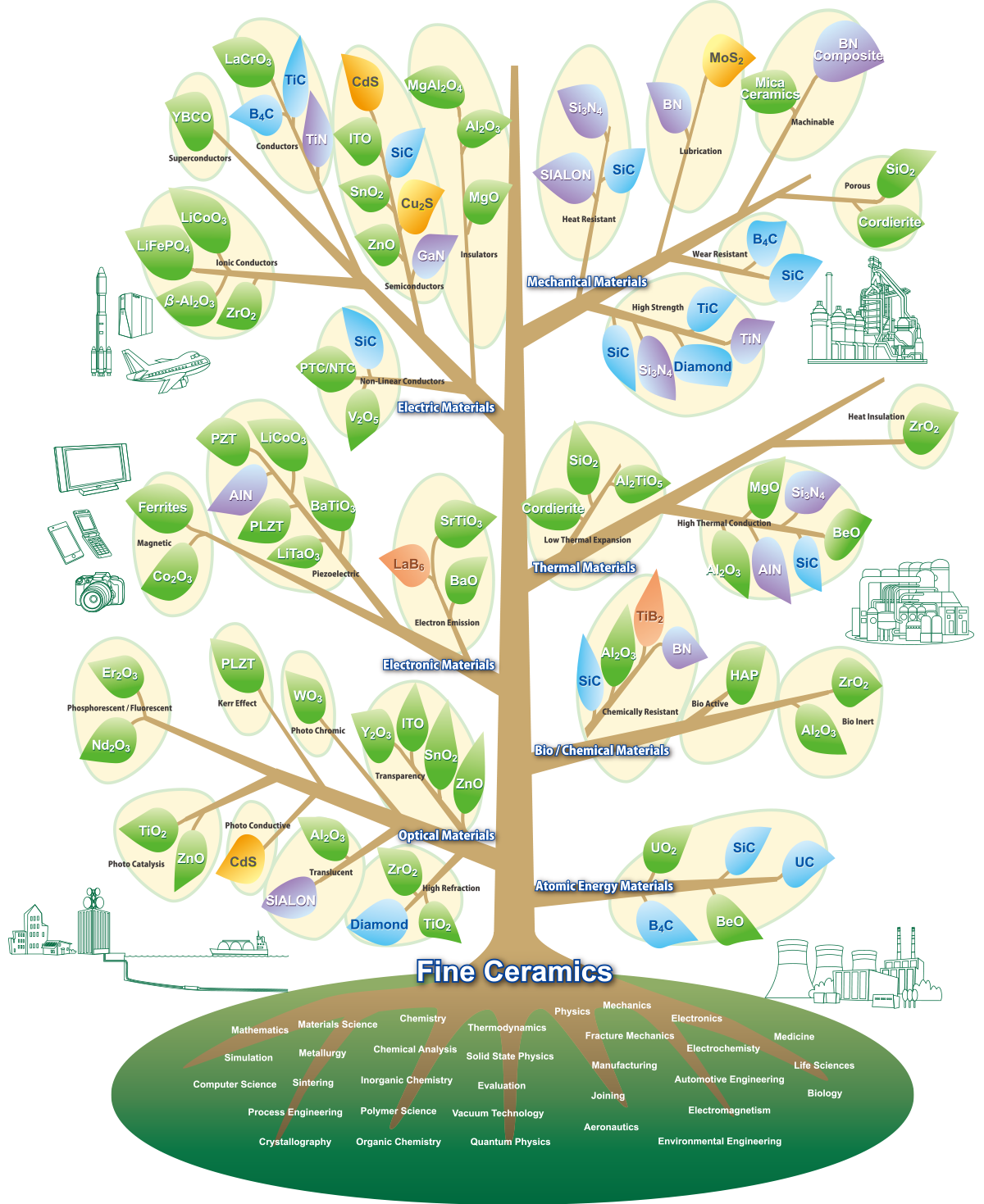

Fine Ceramics, sometimes referred to as "advanced ceramics," are engineered materials that support the development of cutting-edge technology.

Different Types of Fine Ceramics

Wide Variety of Products to Support both Industry and Society

Many choices are available depending on the purpose and application

Fine Ceramics (also known as "advanced ceramics") comprise a wide variety of materials, including alumina, zirconia, silicon carbide and aluminum nitride. Thanks to continuous advances in process technology, different characteristics can be obtained by altering the raw materials, particle sizes and firing methods. As a result, Fine Ceramics can be uniquely formulated for specific performance and functionality in a wide range of applications.

Alumina is the most widely used Fine Ceramic today globally and epitomizes Fine Ceramics. It offers superior mechanical strength, electrical insulation, high frequency retention, thermal conductivity, heat resistance and corrosion resistance. Sapphire is a single-crystal form of alumina.

Zirconia is the strongest and toughest material among Fine Ceramics. It is used to create special blades for high-performance scissors and knives, once considered impossible application.

Single-crystal zirconia is also used in decorative applications and jewelry due to its high refractive index, which produces a diamond-like brilliance.

Among Fine Ceramics, this lightweight, corrossion resistant material offers the highest level of toughness and thermal shock resistance at high temperatures, making it ideal for use in engine components.

This artificial compound is synthesized from silica sand and carbon. It provides the best combination of heat resistance, light weight and corrosion resistance, and maintains its strength at high temperatures (1,500℃ / 2,732℉).

Low thermal expansion gives cordierite superior thermal shock resistance. Due to its porous properties, it is used for honeycomb carriers as well as refractories for electric heaters and industrial chemical equipment materials.

This magnetic ceramic exhibits high permeability, electrical resistance and abrasion resistance. It is widely used in magnetic heads and magnetic cores for high frequency electronics.

Barium titanate is used for capacitors due to its high dielectric constant and superiority in storing electricity. Additives can drastically change its dielectric properties.

A piezoelectric material vibrates when electrical signals are applied, and also converts vibration into electrical signals. Lead zirconate titanate offers strong piezoelectric properties for electronic component applications, such as resonators, buzzers and filters.

Characterized by low microwave loss, superior high temperature insulating properties and a smooth surface, fosterite is suitable for use in electron tubes and circuit boards.

In addition, its high coefficient of thermal expansion is close to that of metals and glass, allowing forsterite to be joined or bonded to these materials reliably.

With a low coefficient of thermal expansion and superior thermal shock resistance, this material is used for heat-resistant components, wire-wound resistive bobbins and electron tube components.

Mullite offers heat resistance, thermal shock resistance and excellent resistance to the structural fatigue mechanism known as "creep." It also displays a coefficient of thermal expansion similar to silicon semiconductor chips, making it useful in semiconductor package applications.

This material offers electrical and mechanical properties superior to conventional porcelains, and excellent machinability.

With excellent thermal conductivity, aluminum nitride is used in applications that require heat dissipation, such as semiconductor packages.

The term "Fine Ceramics" is interchangeable with "advanced ceramics," "technical ceramics" and "engineered ceramics." Use varies by region and industry.

People who read this page also read.

Characteristics of Fine Ceramics

Characteristics of Fine Ceramics

Supporting Our Lives From Behind the Scenes

Supporting Our Lives From Behind the Scenes

Characteristics of Fine Ceramics

Electricity and Magnetism (1)

Electricity and Magnetism (1)

Electrical Insulation to Inhibit Electricity from Passing Through

Electrical Insulation to Inhibit Electricity from Passing Through

Characteristics of Fine Ceramics

Strength (1)

Strength (1)

Extreme Hardness Surpassing that of Metals

Extreme Hardness Surpassing that of Metals

Characteristics of Fine Ceramics

Heat (1)

Heat (1)

Heat Resistance to Withstand Extreme Temperatures

Heat Resistance to Withstand Extreme Temperatures

Characteristics of Fine Ceramics

Chemistry and Medical Care (1)

Chemistry and Medical Care (1)

Highly Resistant to Chemicals

Highly Resistant to Chemicals

Characteristics of Fine Ceramics

If you want to use ceramics in business, click here.

Kyocera's Fine Ceramics products (All websites below open in a separate window.)

Product Category

Semiconductor / LCD Processing Equipment

Semiconductor / LCD Processing Equipment

Life / Culture / Industrial Machines

Life / Culture / Industrial Machines

Wireless Communications

Wireless Communications

Computer Peripherals

Computer Peripherals

Environmental Preservation / Renewable Energy

Environmental Preservation / Renewable Energy

Medical Equipment / Devices

Medical Equipment / Devices

Single-Crystal Sapphire Products

Single-Crystal Sapphire Products

Metallized / Vacuum Components

Metallized / Vacuum Components

Electronics Industry

Electronics Industry

Heaters

Heaters

Piezoelectric Ceramics

Piezoelectric Ceramics

Search by Material

Alumina

Alumina

Silicon Nitride

Silicon Nitride

Silicon Carbide

Silicon Carbide

Sapphire

Sapphire

Zirconia

Zirconia

Cordierite

Cordierite

Yttria

Yttria

Aluminum Nitride

Aluminum Nitride

Cermet

Cermet

Mullite

Mullite

Steatite

Steatite

Forsterite

Forsterite

Search by Property/Characteristic

- Thermal Properties

- Coefficient of Thermal Expansion

- Thermal Conductivity

- Heat Shock Resistance

- Electrical Properties

- Insulation / Semiconductivity

- Chemical Properties

- Chemical Resistance