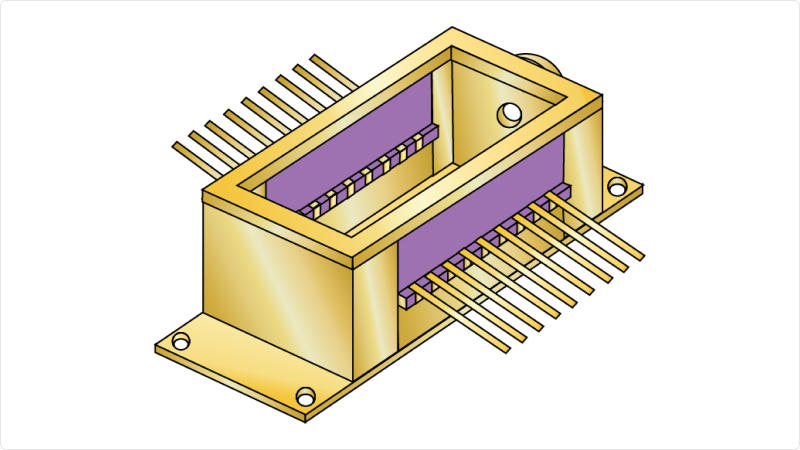

Manufacturing Process: Butterfly Packages

Typical manufacturing processes for butterfly packages are outlined below.

Click here for common butterfly package applications.

Click here for common butterfly package applications.

1. Powders / Formulations

Raw materials are mixed.

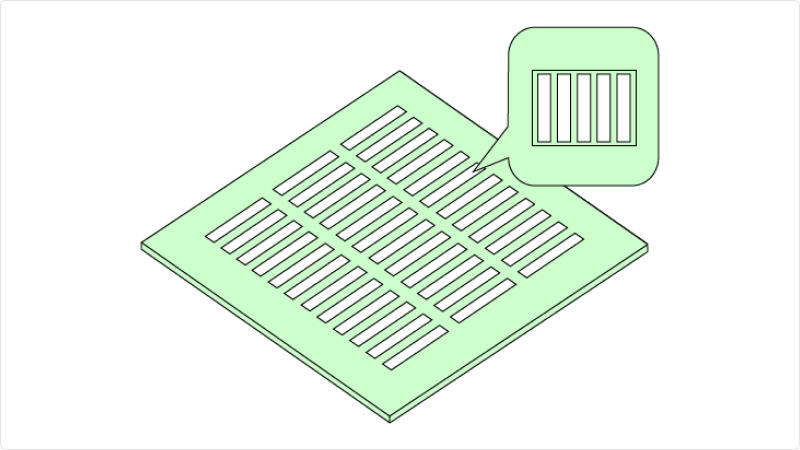

2. Tape Casting

Mixed raw materials are formed into a tape.

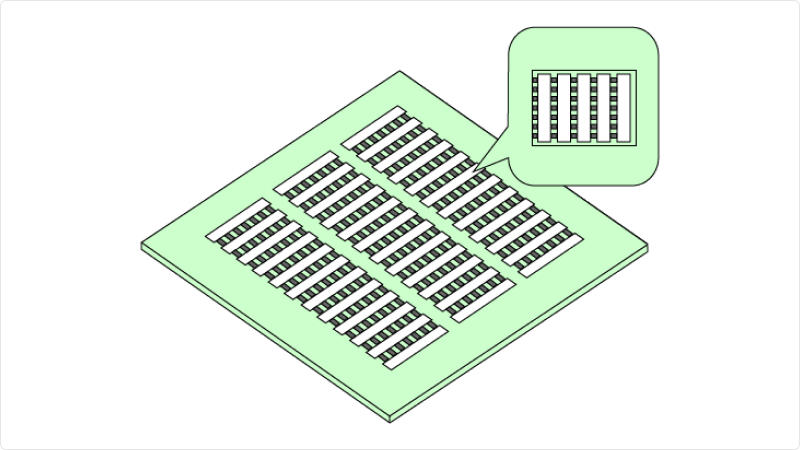

3. Punching

Tape is punched with tooling to make holes for circuit vias and outlines.

4. Via Filling/Printing

Vias are filled with conductive paste to connect different tape layers; tape surface is printed with conductive paste for the circuit pattern.

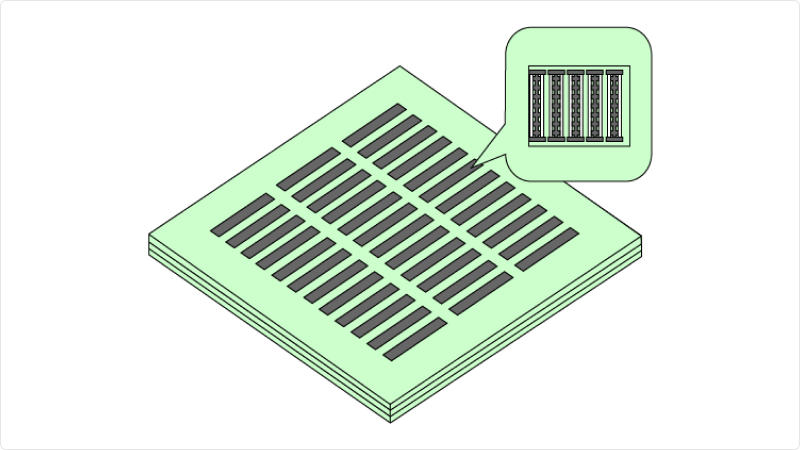

5. Lamination

Circuit-printed layers are stacked and laminated.

6. Firing

Laminated tape is fired in a furnace at high temperature.

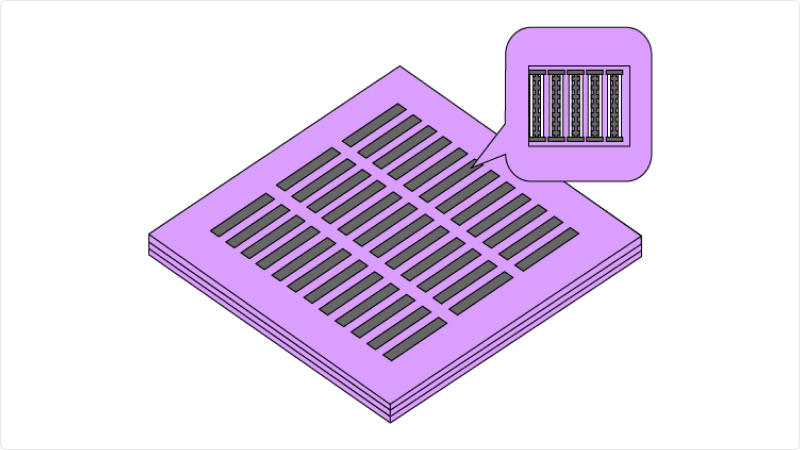

7.Saw Cutting

Fired ceramic is cut into individual feedthroughs using a diamond saw.

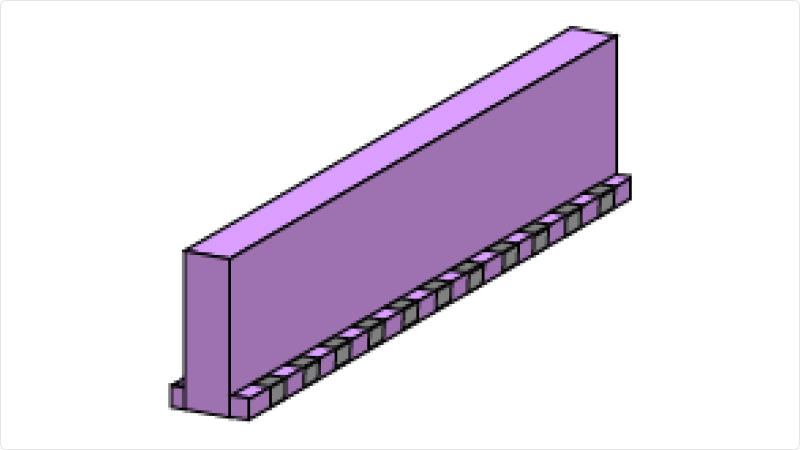

8. Mo-Mn Printing + Firing

Molybdenum-Manganese (Mo-Mn) conductive paste is printed and fired.

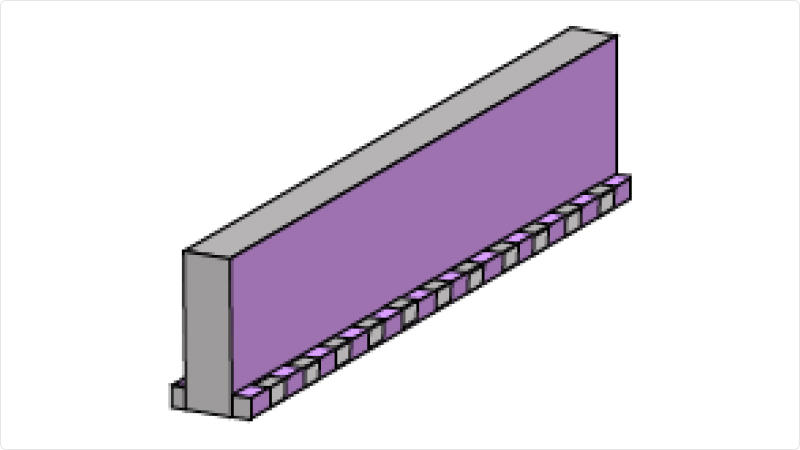

9. Ni Plating

Areas with Mo-Mn metallization are nickel plated.

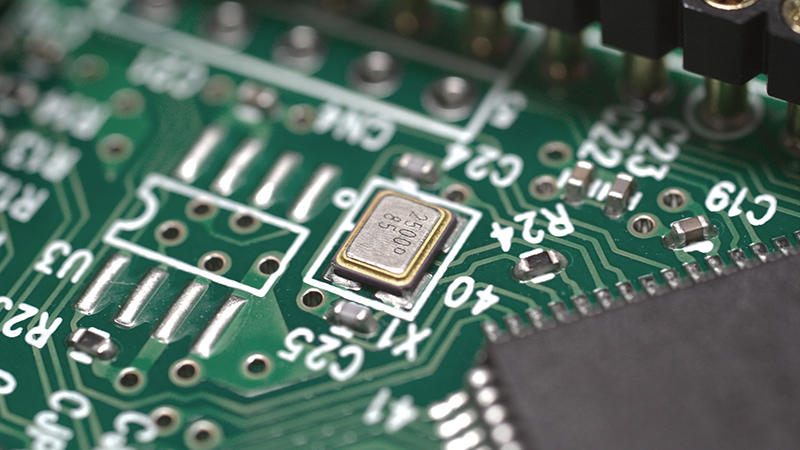

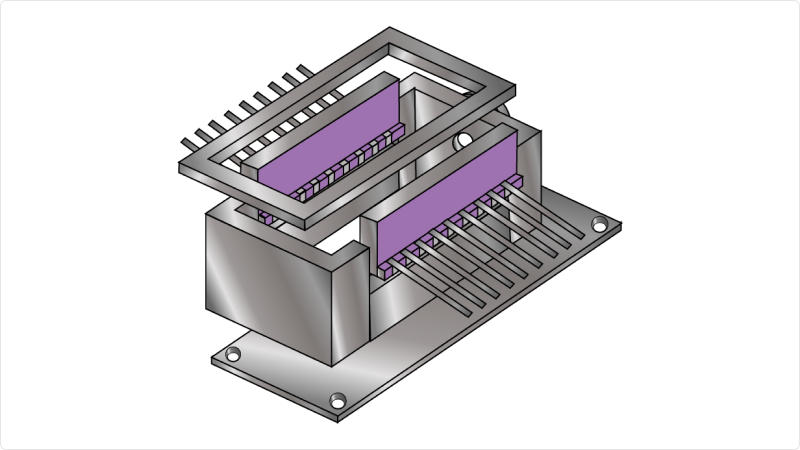

10. Assembly

Multiple metal parts and ceramic feedthroughs are brazed together.

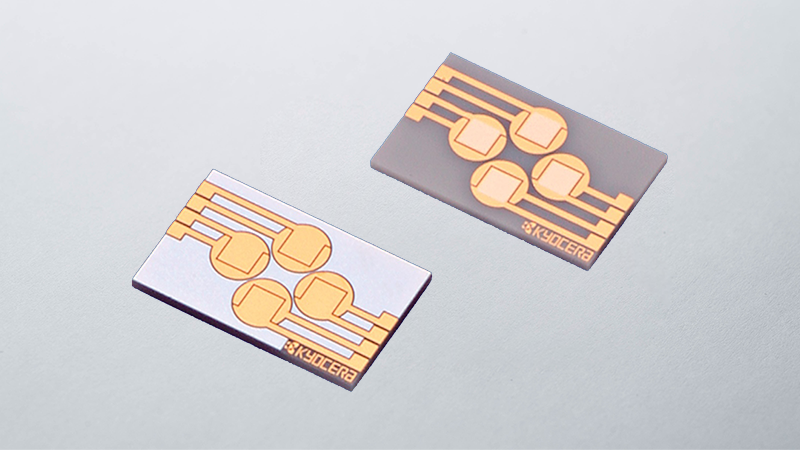

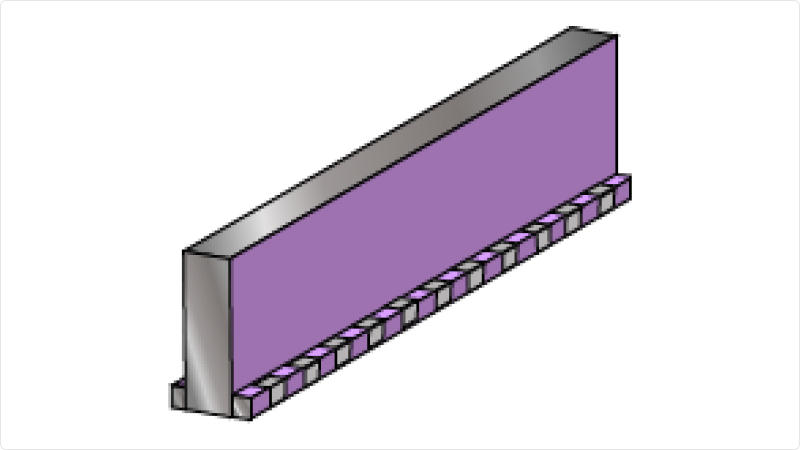

11. Ni Plating + Au Plating

Nickel and gold plating processes are applied sequentially.

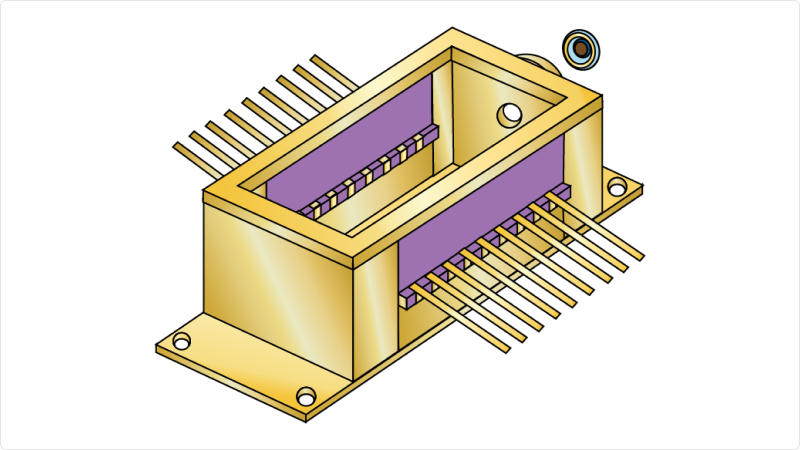

12. Optical Window Assembly

Optical window is assembled into the package.

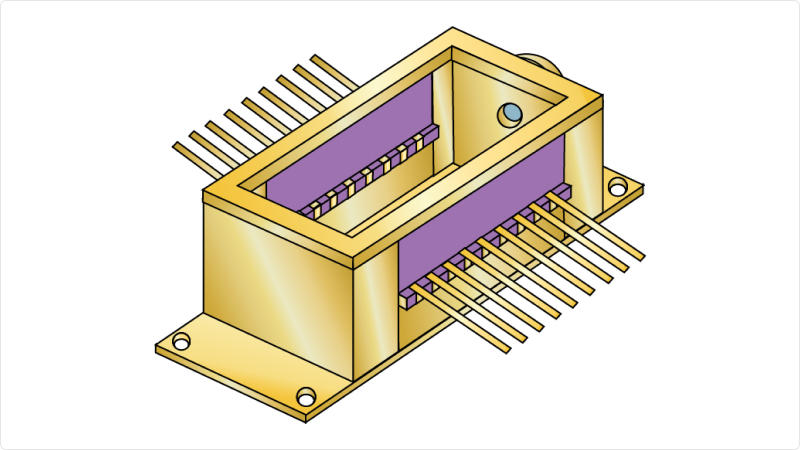

13. Inspection and Shipping

After inspection, finished butterfly package is shipped to customer.