"Fast heating"

Kyocera's ceramic heater is widely used in industrial and automotive applications. Taking advantage of our unique ceramic lamination technology and more than 30 years of experience, Kyocera's heater can deliver robust quality with outstanding performance. The highly reliable ceramic heaters allow customers to minimize the size of the heater while maintaining maximum wattage to support a rapid heating rate. Kyocera works with each customer to provide open-source tools or customized designs to meet your unique performance needs.

BASIC STRUCTURE

Kyocera's ceramic heater has a structure in which a heating element is built into the base ceramic material and is integrated by simultaneous sintering. This structure can completely shut out the outside air, and by embedding multiple circuits, it can also be equipped with an output switching function and a temperature sensor function.

ADVANTAGES

- Rapid heating

- Small size / High watt density

- Long product life

- High insulation

- Direct water and kerosene heating

- Vacuum environment

- Oxidation and chemical resistance

- Output switching

- Temperature sensing

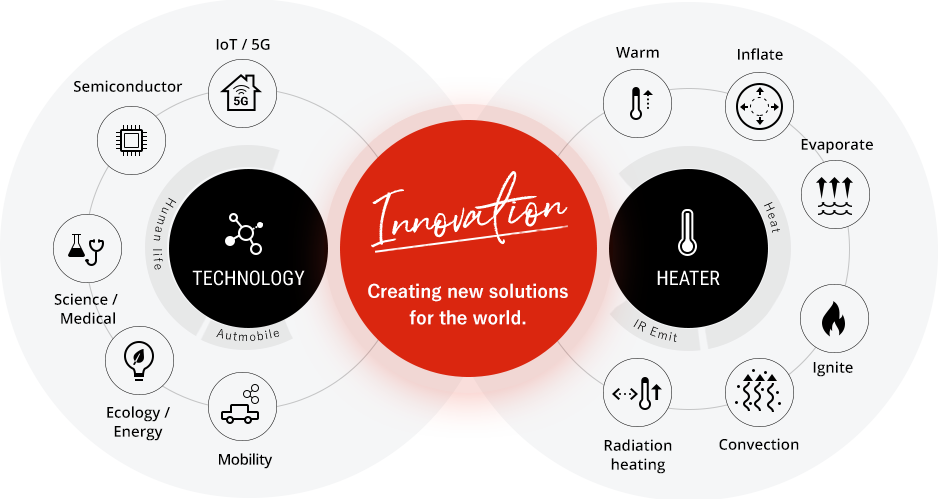

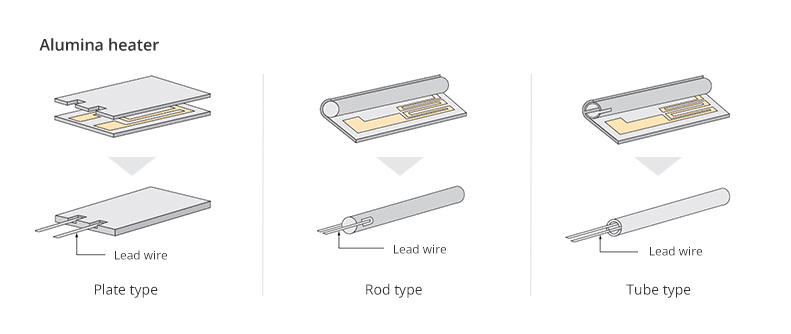

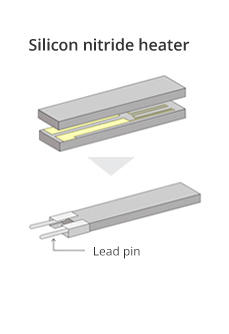

LINE-UP

Kyocera has two types of ceramic material for your heater application, alumina and silicon nitride.

Kyocera will be happy to help you select the appropriate material for your needs.

ALUMINA HEATER

The alumina heater concept was developed based on the ceramic lamination technology developed for ceramic packaging of integrated circuits (ICs). The alumina heater can be found in automobiles, kerosene and gas furnaces, and water heater applications.

SPECIFICATIONS

Standard Specifications

- ・Max operating temperature 1,000℃ MAX

- ・Specific heat (20℃) 0.78×103 J/(kg•K)

- ・Normal operation temperature 800℃ MAX

- ・Linear expansion coefficient (40~800℃) 7.8×10-6/℃

- ・Thermal conductivity (20℃) 18 W/(m•k)

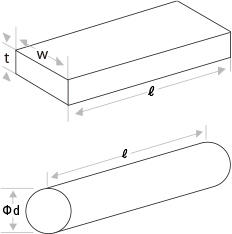

Standard dimensions

Plate type (mm)

- ・Length/Width 160×160 or Φ160

- ・Thickness 0.3~5.4

-

・Tolerance

Length (ℓor w) 20 or more : ±1% /

less then 20 : ±0.2

Thickness 1 or more : ±10% /

less than 1 : ±0.1 - ・Warpage 0.4/100

Rod / Tube type (mm)

- ・Length 120max/200max

- ・Outer diameter Φ2~Φ50/Φ3~Φ20

-

・Tolerance

Length (ℓ) 50 or more:±1%/

less than 50:±0.5

Outer diameter(d) Φ10 or more: ±2%

less than Φ10: ±0.2 - ・Warpage 0.4/100

Please inquire about complex shape requirements, through-holes, bonding to metal, etc

APPLICATIONS

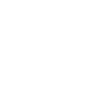

-

IoT / 5G

・Lens defrosteretc.

・Lens defrosteretc. -

Semiconductor

・Electrostatic chuck (ESC)・Stepperetc.

・Electrostatic chuck (ESC)・Stepperetc. -

Science / Medical

・SEM・Chromatograph / Mass spectroscope・DNA analysis equipmentetc.

・SEM・Chromatograph / Mass spectroscope・DNA analysis equipmentetc. -

Ecology / Energy

・Shower toilet・Curling iron・Deodorization ozonizer・Fan heater・Soldering ironsetc.

・Shower toilet・Curling iron・Deodorization ozonizer・Fan heater・Soldering ironsetc. -

Mobility

・Cabin heating for EV・Gas sensor・Thermostatetc.

・Cabin heating for EV・Gas sensor・Thermostatetc.

-

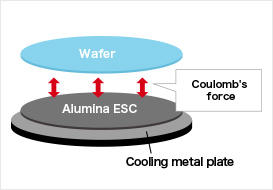

Semiconductor Electrostatic chuck (ESC)

Electrostatic chucks (ESCs) are used in semiconductor manufacturing equipment for adsorption/fixation of wafers/temperature control. Since extremely precise dimension/temperature control is required in the semiconductor manufacturing process, Kyocera's unique pattern simulation and trimming technology achieves minimal dimensional variations and in-plane temperature distribution, contributing to high-quality semiconductor manufacturing.

-

Ecology / Energy Shower toilet

Alumina heater is used as a water heater for bidet toilets to warm the water before showering. Due to quick heating functionality, the preheating tank can be removed, contributing to space savings and power consumption reduction. In addition, the high watt density of the alumina heater also contributes to the miniaturization of the heater unit itself.

-

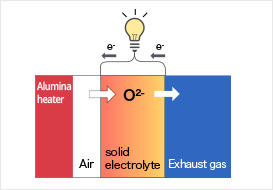

Mobility Gas sensor

Some of gas sensors use a heater to activate the sensor function. For automotive applications, it is used in oxygen sensors in the exhaust system. Kyocera's heater has high durability and rapid heating performance, which contributes to sensor reliability and shorter start up time.

Please feel free to contact us for any other applications not listed above.

SAMPLE PRODUCTS

After receiving an inquiry, our sales team will contact you to confirm your requirement details. Depending on the requirement, we will choose and propose suitable standard samples for evaluation. Information about operation conditions (Voltage/heating performance), size/shape, and applications is highly appreciated.

Standard product

-

- Plate Type

- [ Specifications ]

Voltage:110V/220V

Resistance value:40Ω/70Ω/80Ω/

160Ω/170Ω/175Ω

Output:48-96W

Operating temp. :658-971℃

-

- Rod Type

- [ Specifications ]

Voltage:24V/100V/220V

Resistance value:1.7-450Ω

Output:20W/25W/30W/54W

Operating temp.

:750-1206℃

-

- Tube Type

- [ Specifications ]

Voltage:100V/120V/220V

Resistance value:5.55-22.3Ω

Output:1200W/1600W

*Output at water temperature 42℃

[Note]

- The operating temperatures above are those of the heater itself.

- Please use an electrode temperature of 200℃ or less.

CONTACT FORM

Please feel free to contact us.Kyocera is always exploring ways

to support new innovations and we look forward to finding solutions to your challenges.