Growing Demand of Gas Sensors

Gas sensors detect flammable gas, toxic gases, alcohol, etc. In recent years, in order to achieve sustainable development goals, the application of gas sensors has diversified with activity to reduce emission of CO₂ which is cause of global warming, and stricter regulations on air quality in the workplace. In manufacturing sites, demand for CO₂ sensors is increasing for CO₂ monitoring. Similarly, attention of air quality indoors and outdoors is increasing, and there are needs for monitoring air quality in various locations. Ex; BEMS (Building Energy Management System)

Outdoors

Vehicles

Offices

Buildings

NDIR Gas Sensors for CO₂ Sensing

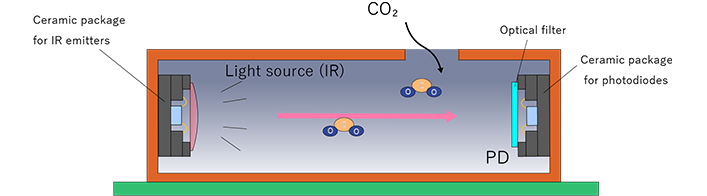

NDIR (Non-Dispersive InfraRed) gas sensors which use a IR light source is mainly used to detect CO₂. From above background, the demand for NDIR gas sensors is expected to increase. Kyocera offers new "Ceramic Package" solutions for NDIR gas sensors.

New Packaging Solution for NDIR Gas Sensors

"Ceramic Package" which can be used for IR emitters / Photodiodes

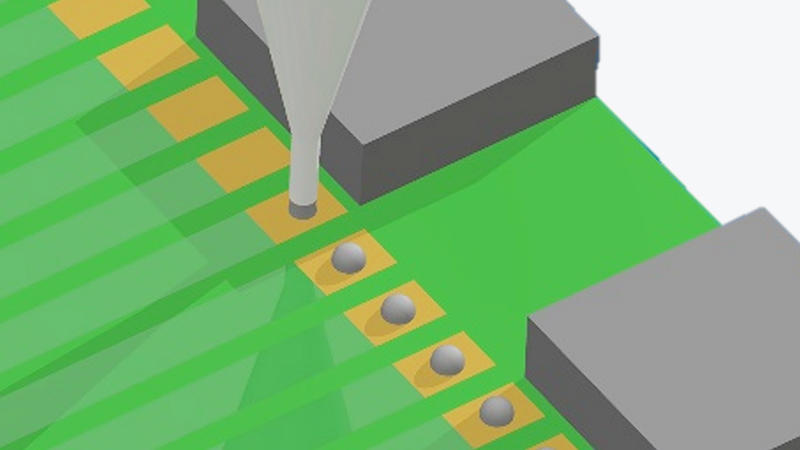

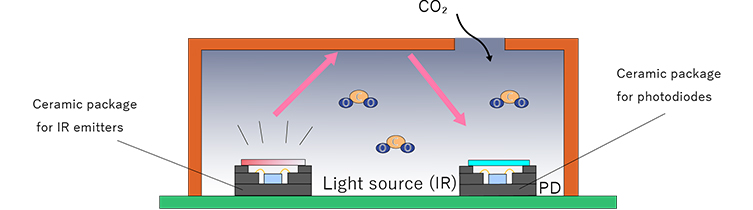

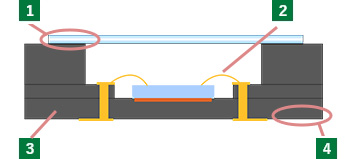

For NDIR gas sensors, IR emitters for the IR light source and photodiode for receiving IR are required. The two types of NDIR gas sensor are shown as below.

Contrast Type

Reflection Type

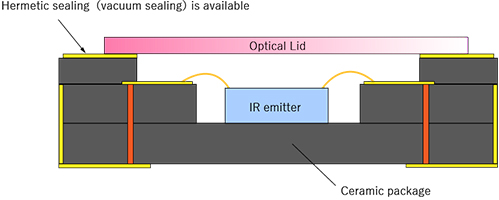

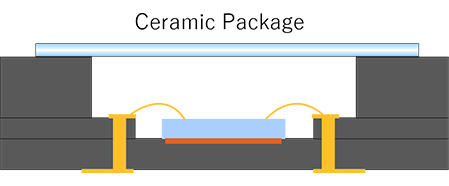

Ceramic Packaging for IR Emitters

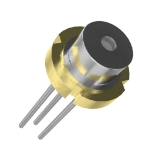

LED and MEMS micro-heaters etc. are used in IR emitters. By replacing the TO-CAN package with a ceramic package, smaller and thinner package design is possible by surface mounting without lead or pin.

Packaging for IR emitter

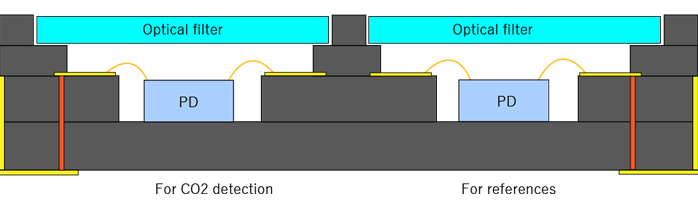

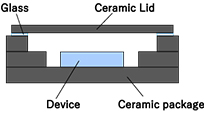

Ceramic Packages for Photodiodes

Photodiodes, thermistors, thermopiles and pyroelectric sensors are used for photo detector. Using a ceramic package allows for hermetic and/or vacuum sealing solutions which are challenging for organic package solutions. Therefore, sensitivity improvement can be expected by using a ceramic package.

Moreover, since ceramic packages can easily realize 3D structure by lamination, it is easy to form cavities which optical filters can be put on, and it is also possible to attach two photodiodes for CO2 detection and reference in one package for dual wavelength detection method.

One Package for

Dual Wavelength Detection

Additionally, ceramic package characteristics include less out gassing, higher heat dissipation, and higher heat resistance, allowing ceramic package solutions to keep higher sensing accuracy even in a harsh environment, such as vehicle applications.

Kyocera has product lineup for optical lid

Features of Ceramic Packages

for Gas Sensors

1<Sealing Technology>

- Seal with glass, silicon and germanium etc.

- Hermatically sealing

- Vacuum sealing

2<Flexible Cavity Design>

- Protects chip and wire by cavity

- Improves assemble reliability by W/B shelf

3<Ceramic package>

- High durability

- High heat resistance

- Less out gas

- Similar CTE to Silicon

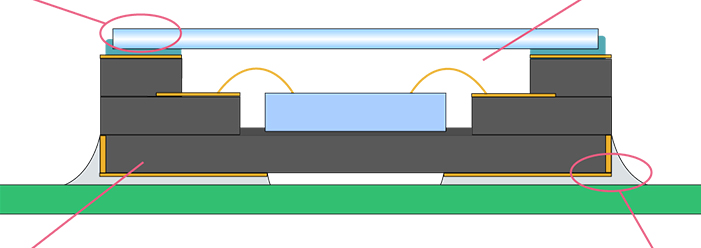

4<2nd Assembly>

- Surface mounting / Reflow process

- Side metallization

Improves assembly reliability by solder fillet

Comparison of Ceramic Packages

and Other Materials

Comparison with Metal CAN Packages

Miniaturization and thinner by switching to a ceramic package

Metal CAN Package

Ceramic Package

From pin insertion assembly to reflow surface assembly

Smaller and thinner package designs by 3D pattern routing

Design proposal by customized package

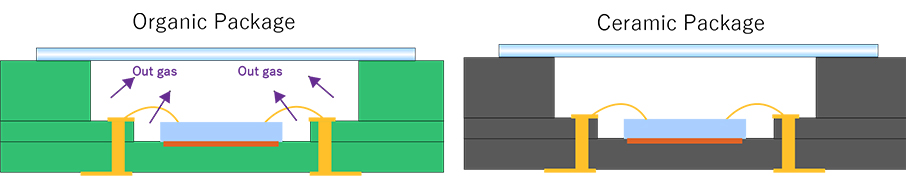

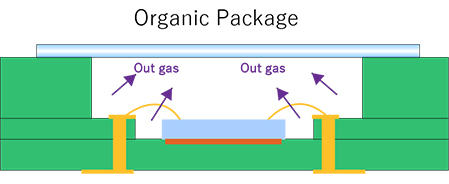

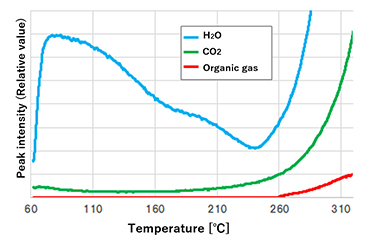

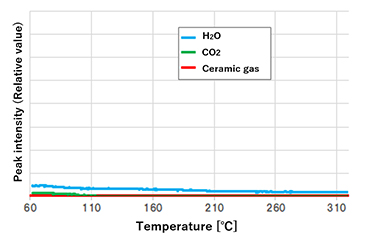

Comparison with Organic Packages

Less out gas than organic packages

Ceramic has less out gas (ex. CO₂) than organic material in high-temperature environments. Therefore, ceramic packages are more useful for improving the accuracy of gas sensing.

Out Gas Comparison with Organic Package

*Analysis method : Continuous temperature rising GC-MS(60~310℃)

Out Gas from Organic Packages

Out Gas from Ceramic Packages

*Analysis was conducted by Kyocera

Ceramic packages is possible to make the gas sensor smaller and thinner. Moreover, ceramic package has less out gas under high-temperature environments, high heat resistance, high rigidity, and close CTE to Si, which improves mounting reliability. Therefore, ceramic package will be suitable option for high reliability applications.

Sealing Options

for Ceramic Packages

| Sealing method | Glass (Frit) |

Resin (Epoxy) |

AuSn / Solder |

Seam weld | |

|---|---|---|---|---|---|

| LID Material |

Ceramic | ||||

| Metal | |||||

| Sealing Temp. |

340℃~ | 120-150℃ | 320℃ | ~200℃ (Chip area) |

|

| Positive Points |

High productivity (Continuous tunnel furnace) |

Low temp. sealing (~150℃) (Low heat stress on chip) |

Low heat stress | Low stress on chip |

|

| Negative Points |

Higher seal. temp. Pb included Frit |

Low-productivity Non-hermetic (Moisture permeation) |

Higher seal. temp. Pb including solder |

Low productivity High seal. stress |

|

| Note | Pb free Frit is available (Seal temp. 460℃) |

Glass lid / Si lid is available B stage(Semi-cured) epoxy is applied for epoxy LID |

AuSn vacuum seal. is available |

Vacuum seal. is available |

|

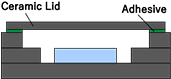

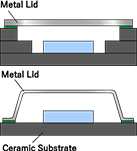

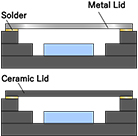

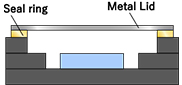

| Structure PKG/LID (Ex.) |

|

|

|

|

|

*Kyocera proposes a suitable sealing method based on customer requirements.

There are open tool products which are suitable for each of the above sealing methods.

Flexible Shipping Form

for Various Assembly Methods

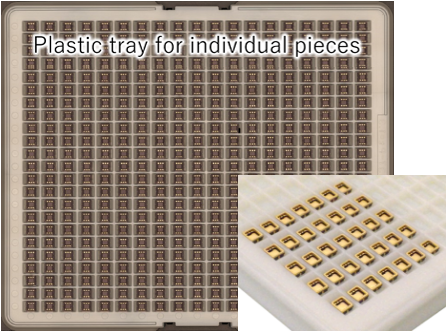

Singulated Shipment

Singulated package is mounted on plastic tray

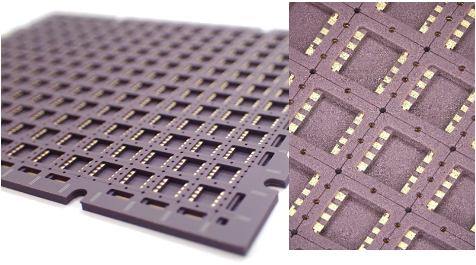

MAT Shipment®

※MAT:Metal frame

with Adhesive Tape

Singulated package is mounted on adhesive tape.

Metal frame material : SUS

*MAT shipment is registered trademark of Kyocera corporation

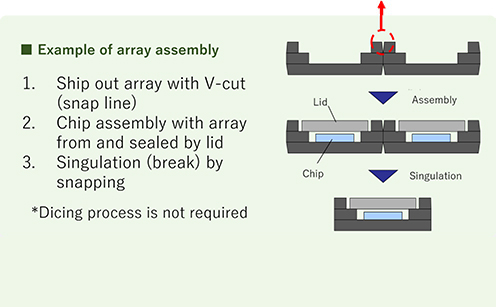

Array Shipment

Array with V-cut (snap line)

Array with V cut (snap)

⇒Singulation is easily realized after assembly process

Flexible shipping option can be offered.

Please kindly consult us if there is request for shipping form.

Ceramic Package is Usable

for Various Types of Gas Sensors

Metal Oxide

Gas Sensors

According to the trend of MEMS chip-based gas sensor, packaging has been shifted from TO-CAN to SMD type.

Multi-layer ceramic package which has 3D pattern rooting can support development of smaller and thinner gas sensor.

Electrochemical

Gas Sensors

Electrochemical gas sensor is based on chemical reaction principle and used for high accuracy application for CO, NOx gas and so on.

Alumina, which is a ceramic material, has strong chemical resistance and less chemical reaction to acid and alkaline

solutions. Therefore, ceramic packages are usable for electrochemical gas sensors.

Other

Gas Sensors

Ceramic packages can be used for various type of gas sensors, such as hydrogen, oxygen, smell sensor and so on. With open tool product lineup, it is possible to conduct evaluation without tooling cost.

Send open tool drawing /

Generate custom drawing /

Submit quotation

Please feel free to contact us.