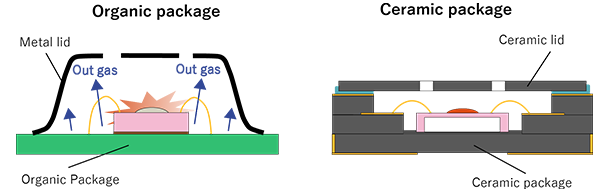

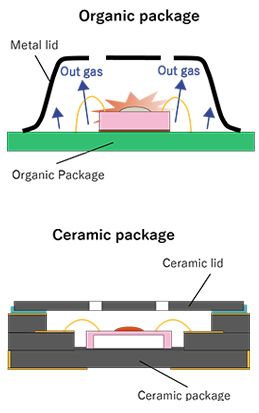

1<Sealing Option>

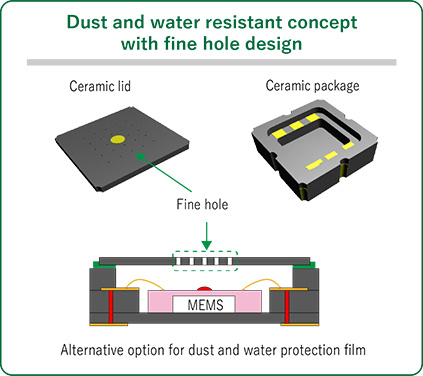

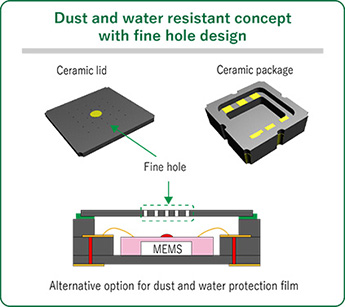

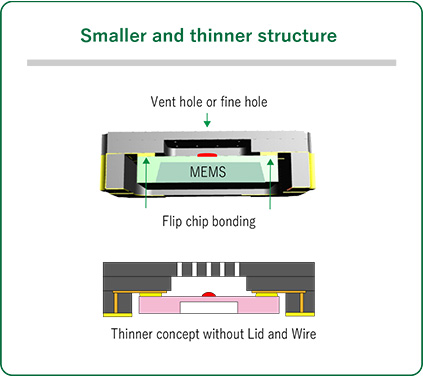

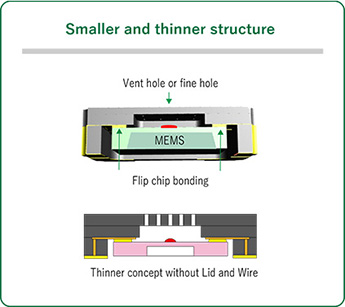

- • Ceramic lid

(High heat resistance / less out gas material) - • Fine hole concept

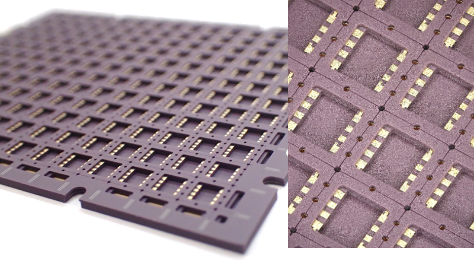

2<Flexible Cavity Design>

- • Protects chip and wire by cavity

- • Improves assembly reliability with W/B shelf

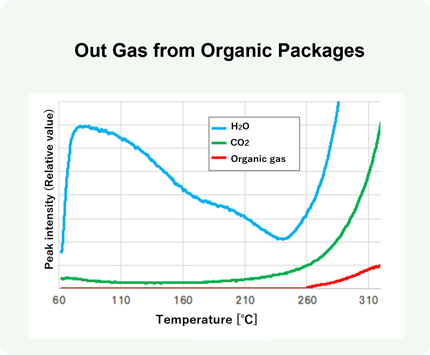

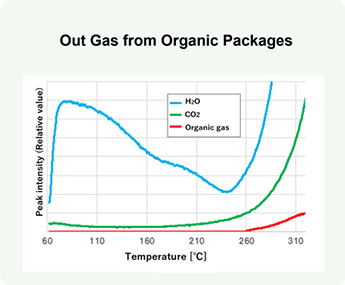

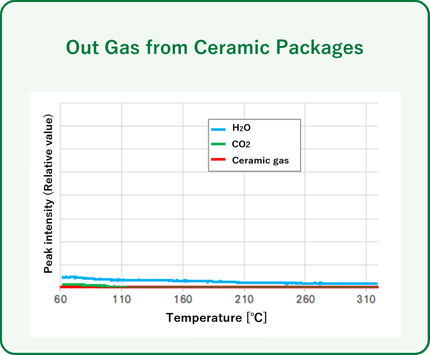

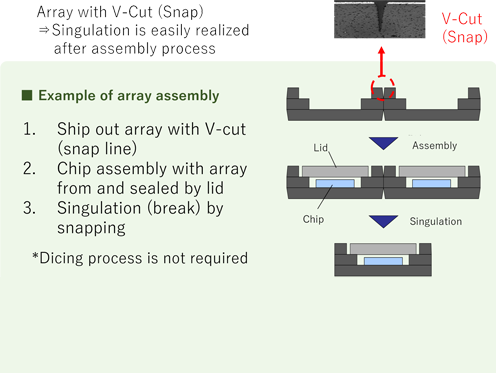

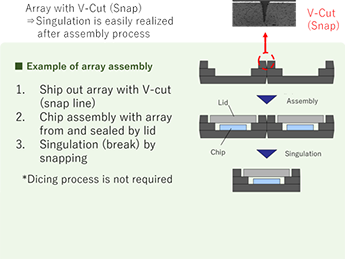

3<Ceramic Package>

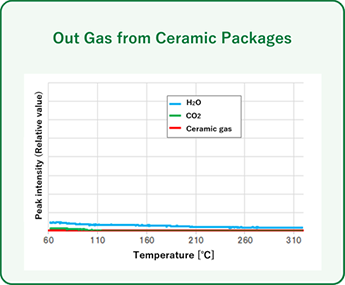

- • High durability

- • High heat resistance

- • Less out gas

- • Similar CTE to silicon

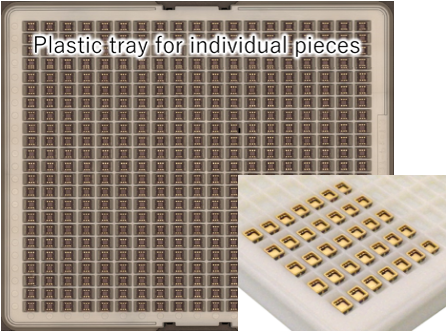

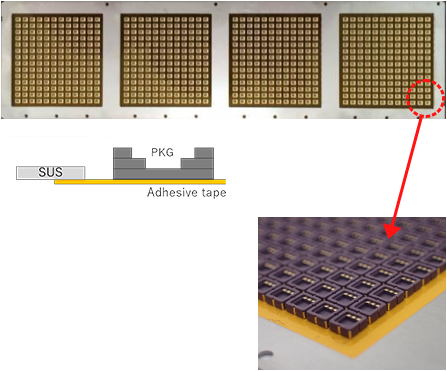

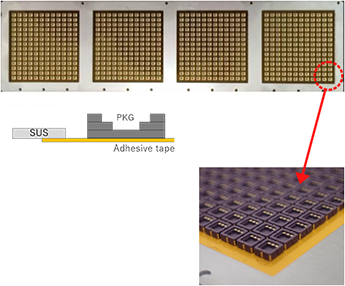

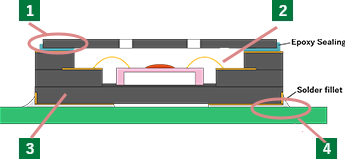

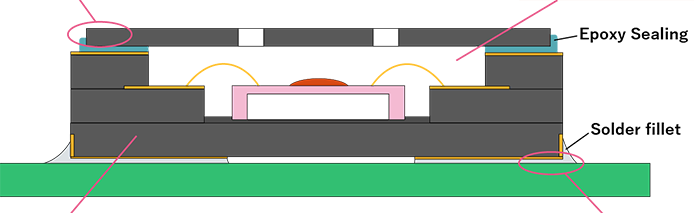

4<2nd Assembly>

- • Surface mounting / Reflow process

- • Side metallization

Improves assembly reliability by solder fillet