Improved Dispensing Accuracy

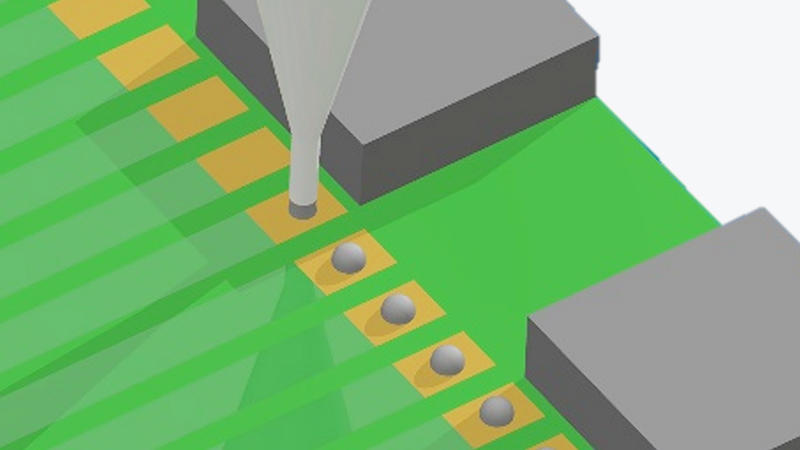

As technology evolves, electronic devices are becoming smaller, lighter, and thinner, and the electronic components they contain are also becoming smaller and more densely mounted. Every market is demanding higher-precision mounting, which is essential in assembling larger numbers of smaller electronic components on densely populated circuit boards.

Do you have trouble bonding and mounting electronic components with high precision?

-

Replacing equipment is costly.

Do you want to improve dispensing accuracy without replacing your existing equipment?

-

Dispenser settings alone offer limited control.

Do you want to improve your equipment's accuracy in dispensing diameter and volume?

-

Developing new adhesives/materials is time-consuming.

Do you want to improve your dispensing accuracy without changing the adhesives/materials you currently use?

-

Dispensing diameter varies over time.

Do you want to maintain precise dispensing diameter during extended use?

-

Nozzle maintenance is troublesome.

Do you want to reduce downtime caused by nozzle cleaning and replacing clogged nozzles?

Dispensing accuracy and stability

can be improved by optimizing your dispenser nozzles.

Several strategies exist to improve dispensing accuracy and stability when bonding and mounting electronic components. Generally, optimizing equipment settings is the first step. If this doesn't provide the required accuracy or stability, then changing the dispensing material or investing in new high-precision equipment may be considered as a drastic solution.

However, this introduces other challenges, such as incurring significant capital expenditure and losing the knowledge and experience accumulated with existing equipment.

A much simpler solution can often be found in simply changing dispenser nozzles.

Nozzles can be selected to optimize dispensing performance with coating, adhesive, or soldering materials.

Why would you consider optimizing your dispenser nozzles?

Kyocera offers engineered ceramic dispenser nozzles.

By replacing your current nozzles with ceramic, you can expect improved dispensing accuracy and stability.

This alone can often provide the dispensing accuracy and stability you need without investing in new equipment or changing materials. You can enjoy significant process improvement with tremendous savings in time and cost compared to developing processes for new materials or investing in new equipment.

Types of Dispenser Nozzles

Precision Metal Nozzles

Advantages

- Easy to mass-produce; cheap

- Effective well in narrow and deep mounting areas

Disadvantages

- Manufacturing process tends to leave burrs causing clogging and large variations in dispensing diameters

- Require frequent maintenance

- Difficult to produce in smaller inner diameters (as compared to ceramic and ruby nozzles)

Ceramic Nozzles

Advantages

- No burrs; available in longer lengths with thinner walls

- Effective well in narrow areas and deep mounting areas

- Maintain stable dispensing diameters over extended use

- Lower cost than ruby nozzles

Ruby Nozzles

Advantages

- No burrs

- Maintain stable diameters over extended use

Disadvantages

- Not suitable for narrow or deep mounting areas

- Most expensive of the three types

Comparison of Dispenser Nozzles

Comparison Chart by Material

+++: Excellent ++: Good +: Average -: Poor

| Precision Metal Nozzles | Kyocera Ceramic Nozzles | Ruby Nozzles | |

|---|---|---|---|

| Price | +++ | ++ | - |

| Dispensing Accuracy |

- | ++ | +++ |

| Tip Wall Thickness |

++ | ++ | + |

| Tip Elongation |

++ | ++ | - |

Researched by Kyocera

Differences by

Dispenser Nozzle

▼

Kyocera Ceramic Nozzle

Product Specifications

▼

Kyocera Ceramic Nozzle

Specifications (Standard Product)

▼

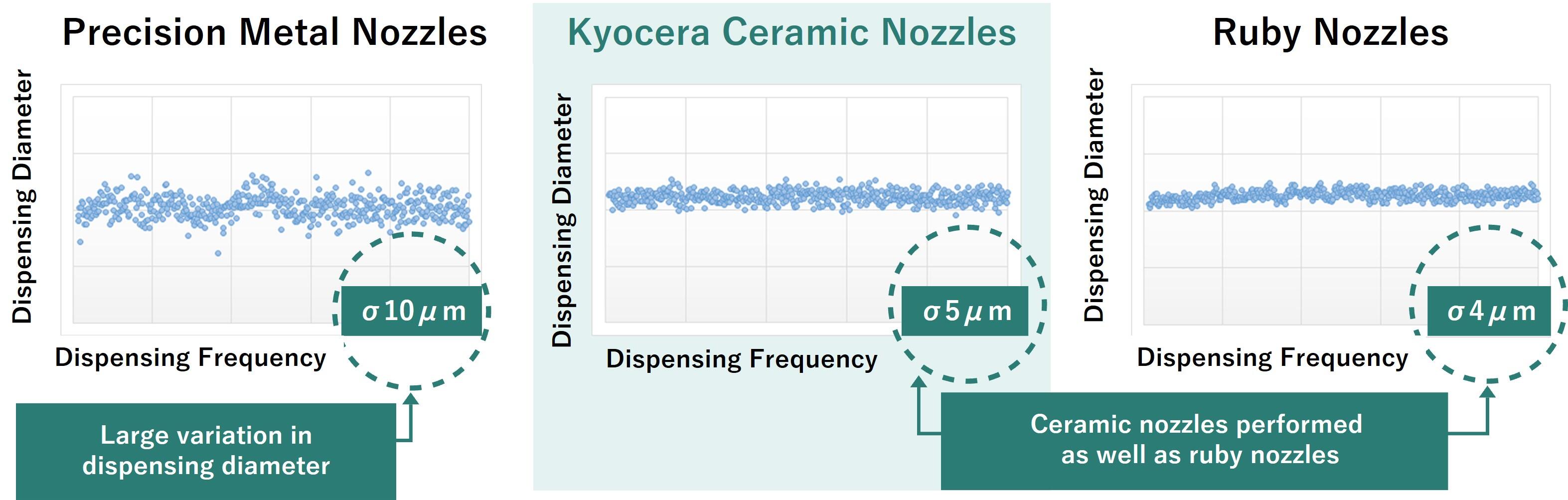

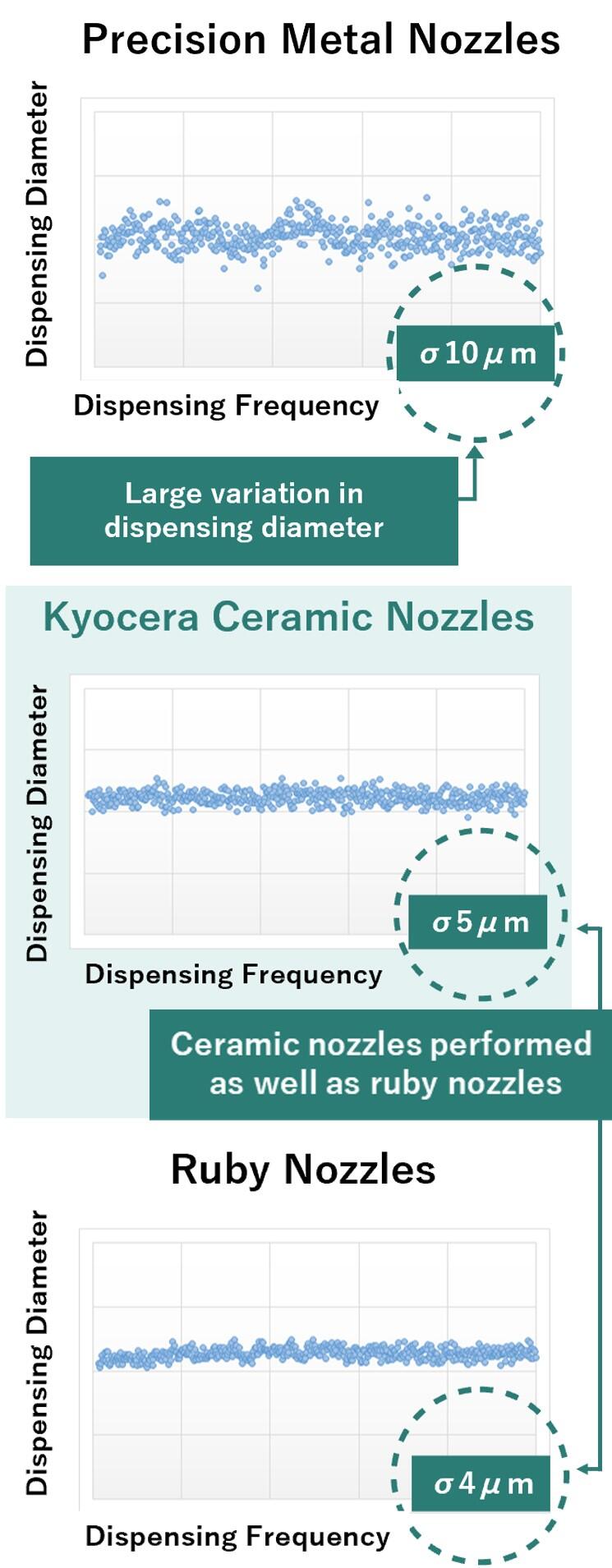

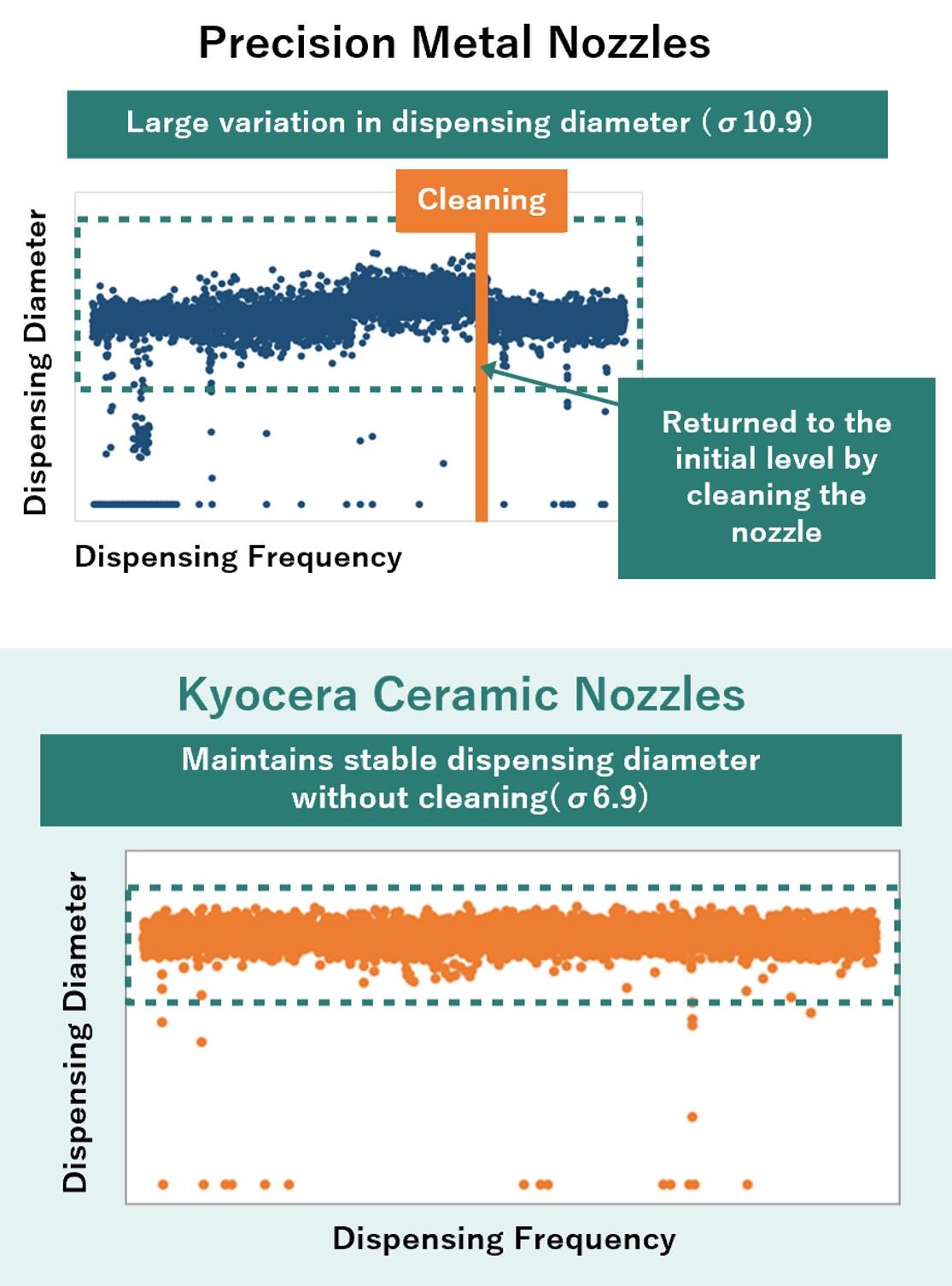

Differences in Dispensing Accuracy and Stability by Nozzle Type

Dispenser nozzles with a tip inner diameter of 0.07 mm were used to compare dispensing diameter variation. Silver paste was used as the dispensing material. Testing confirmed that the "ceramic nozzle" and "ruby nozzle" could continuously dispense while maintaining a stable dispensing diameter, while the "precision metal nozzle" showed a large variation.

*Measured by Kyocera

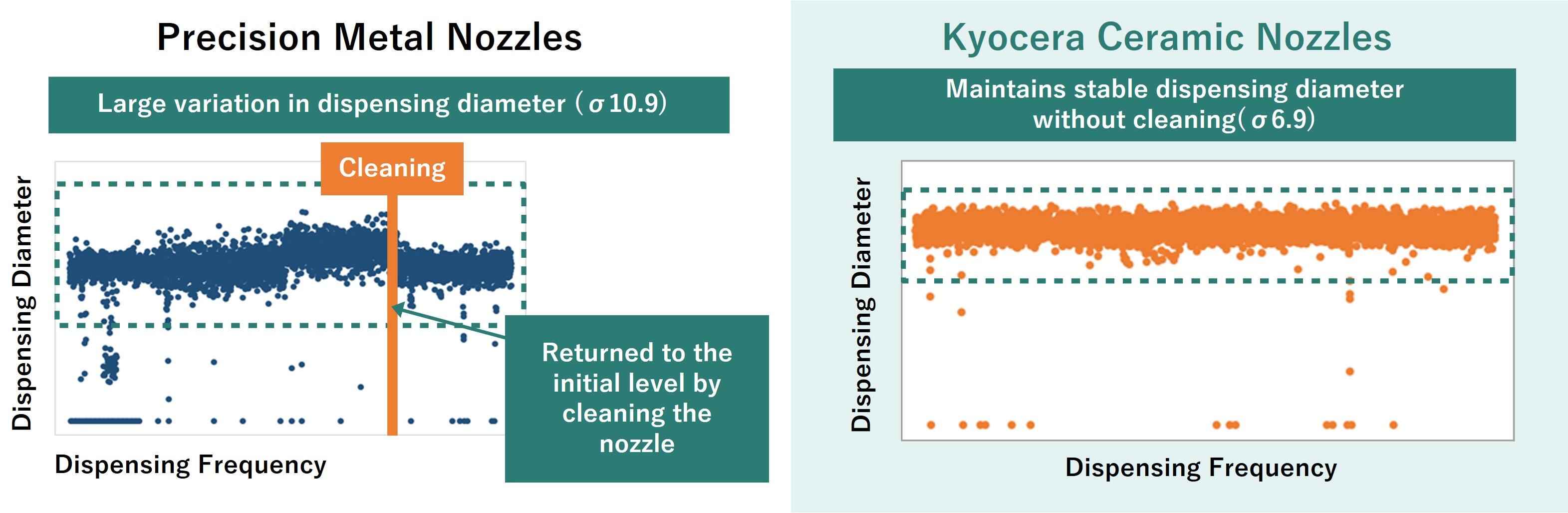

Difference in dispensing accuracy and stability between “Precision Metal Nozzles” and “Ceramic Nozzles”

Precision metal nozzles and ceramic nozzles were compared in terms of dispensing accuracy and stability.

Precision metal nozzles tended to increase in dispensing diameter with continuous use and returned to the initial dispensing diameter after cleaning, while the ceramic nozzles maintained a stable dispensing diameter even without cleaning.

Measured by Kyocera

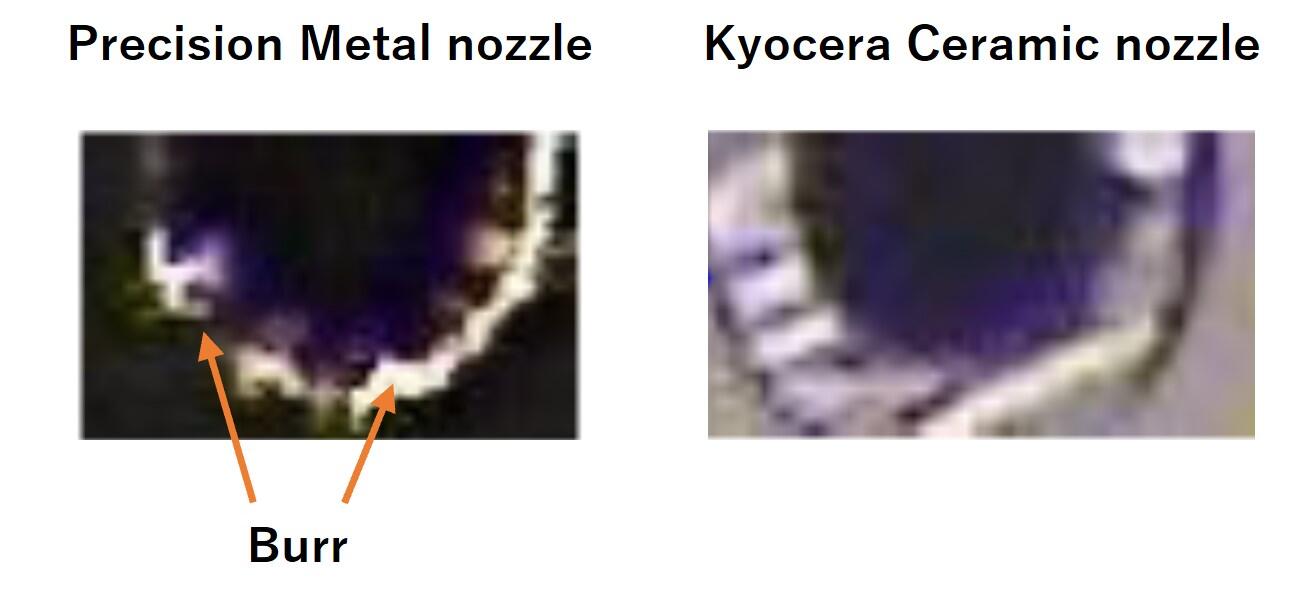

Precision metal nozzles require machining at the tip of the nozzle during manufacturing.

Because burrs are generated during the machining process, large variations are often observed in dispensing diameters.

In contrast, ceramic nozzles are made by grinding co-fired ceramics, so there are no burrs. Therefore, dispensing diameters remain stable.

| Burr |

|---|

|

Comparing inner diameter surface roughness, the "ceramic nozzle" has a smaller surface roughness than the "precision metal nozzle" and enhances superior dispensing accuracy.

Kyocera's "ceramic nozzles" were developed using ceramic molding and precision processing technologies. Inner and outer diameters can be designed with a high degree of freedom, and the concentricity of inner and outer diameters is strictly controlled, making them suitable for precision equipment such as 3D printers.

| Comparison of inner diameter surface roughness |

||||||

|---|---|---|---|---|---|---|

|

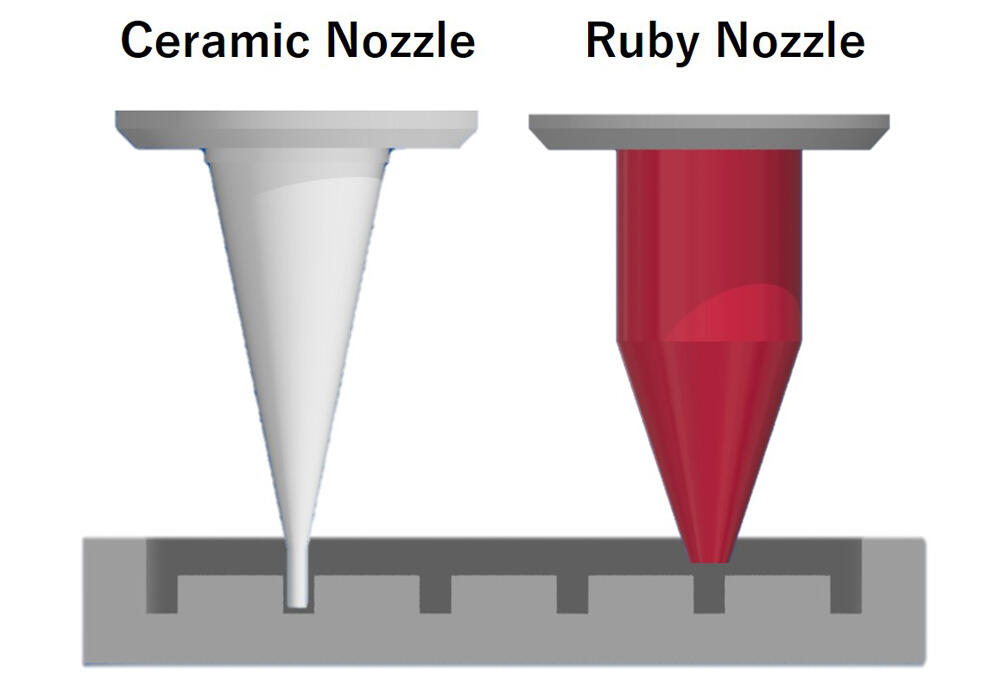

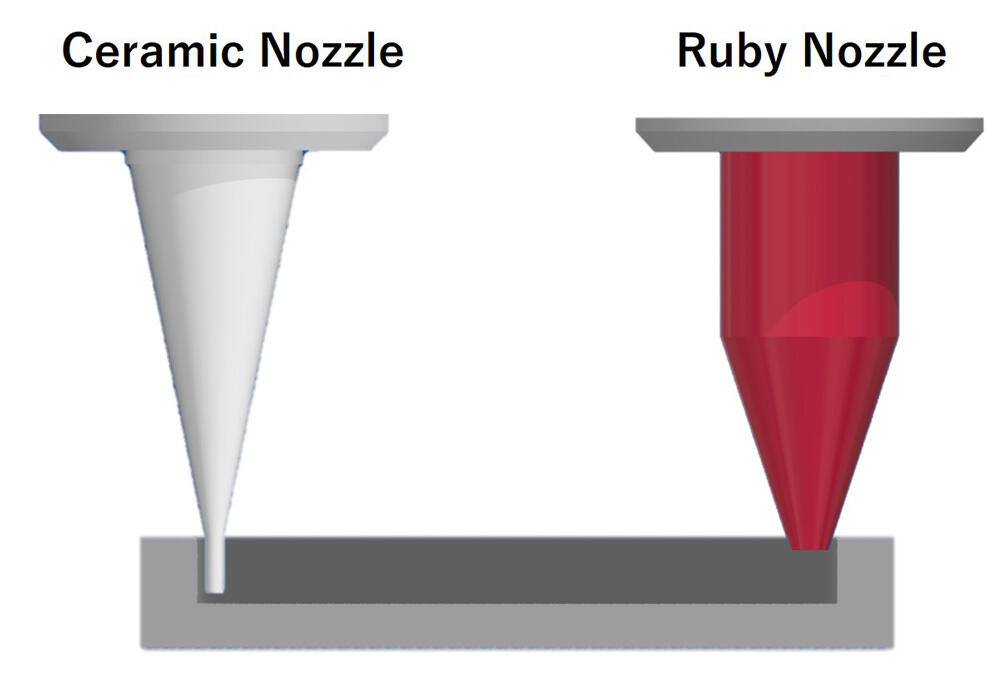

Difference between ruby nozzle and ceramic nozzle

Ruby nozzles have a narrower inner diameter and can handle smaller dispensing diameters, but their thicker minimum wall thickness results in a larger nozzle outer diameter. Ceramic nozzles, in contrast, can accommodate smaller nozzle diameters because their wall thickness can be made thinner at the tip. This enables high-precision dispensing without interference between the nozzle and the component, even in narrow areas where electronic components are mounted in proximity. Since the tip can be made longer, a stable dispensing diameter can be maintained even in deep mounting areas that the “ruby nozzle” cannot reach.

Ruby Nozzle

Nozzle outer diameter increases due to thicker wall

- ・Extremely thin nozzles (from 0.02mm) can be made

- ・Cannot offer tip with thinner wall thickness

- ・Not available in longer tip lengths

Kyocera Ceramic Nozzle

Nozzle outer diameter can be reduced because the wall thickness can be made thinner

(*In case of 0.07mm inner diameter, 0.1mm nozzle outer diameter is possible.)

- ・Nozzles with narrow inner diameters (0.07mm and up) are available

- ・Longer tip lengths (up to 3.0mm) are possible

Advantages of Ceramic Nozzles Over Ruby Nozzles

-

Where space between mounted components is narrow

Ceramic nozzles avoid interference with mounted components

-

When dispensing is required near a wall

Ceramic nozzles avoid interference with package walls and tall components

In terms of cost, ceramic nozzles are less expensive than ruby nozzles, which also reduces operational expenses.

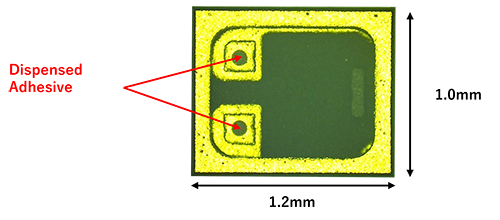

Example of dispensing into a package with cavity for miniature crystal element

Photograph of adhesive applied to an ultra-small PAD with dimensions of 0.2mm SQ

(Dispensing diameter: approx. 80µm)

(Courtesy of PFA Corporation)

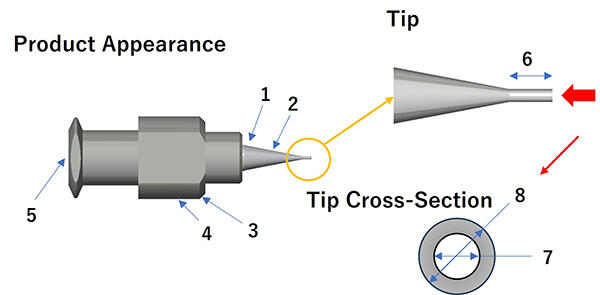

Kyocera Ceramic Nozzle Product Specifications

Kyocera ceramic nozzles can be custom-designed for demanding operating requirements.

Please see below for information on changing or replacing dispenser nozzles.

| Number | Item | Spec / Material / Shape |

|---|---|---|

| 1 | Ceramic material | Zirconia |

| 2 | Taper shape | Customization possible |

| 3 | Material of metal part | SUS303/ SUS304/ Nickel plated brass |

| 4 | Shape of metal part | Customization possible |

| 5 | Connection part | Luer taper / double thread |

| 6 | Tip straight length | 0.10 to 3.00mm (can be changed as desired) *Depending on conditions, #8 may be limited in order to ensure strength. |

| 7 | Tip inner diameter | Φ0.05 / 0.07 / 0.10 / 0.15mm *Tolerance range is 0.002mm |

| 8 | Tip outer diameter | #7 (Tip inside diameter) + 0.03mm or more *#6 may be limited under certain conditions to ensure strength. |

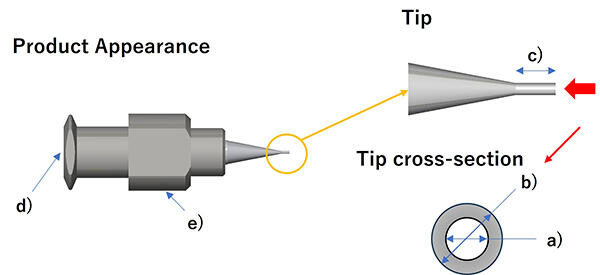

Kyocera Ceramic Nozzle Specifications

(Standard Product)

Please check the specifications below.

| Number | a) Tip innner diameter |

b) Tip outer diameter |

c) Tip straight length |

d) Connecting part |

e) Material of metal part |

|---|---|---|---|---|---|

| Z0223S01B-0510R | 0.05mm | 0.10mm | 0.20mm | Lure taper |

SUS303 |

| Z0223S01B-0712R | 0.07mm | 0.12mm | 0.20mm | Lure taper |

SUS303 |

| Z0223S01B-1016R | 0.10mm | 0.16mm | 0.20mm | Lure taper |

SUS303 |

| Z0223S01B-1520R | 0.15mm | 0.20mm | 0.20mm | Lure taper |

SUS303 |

Please feel free to contact us.

Please feel free to consult us about any issues you may have on-site.

Various custom solutions are also available.

Contact us