The global race to create a better EV design gets a boost from AI-driven advances

AI revolutionizes complex system design, reinventing EV development at "Anser"

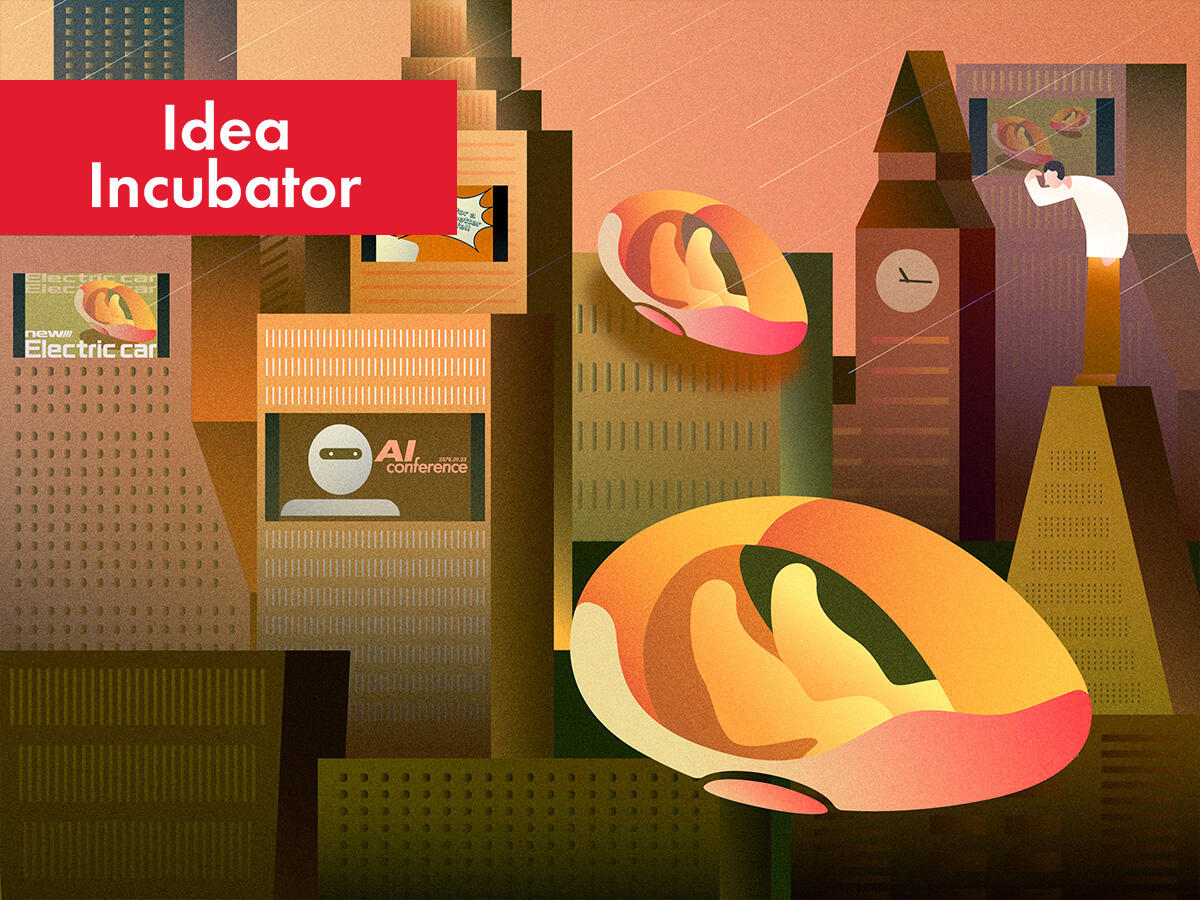

“I believe that advancements in sophisticated machine learning, computer science, state-of-the-art algorithms, and AI will enable us to understand complex systems like cars and airplanes as a whole. We’ll be able to design every component in an integrated way and create optimal products.”

The above high expectations of AI and other cutting-edge technologies belong to Dr. Jaroslaw Rzepecki (known as Jarek), CTO of Monumo. Anticipating that demand for cost-efficient EVs will grow, he and his team developed "Anser," a software that integrates AI, machine learning, and multiphysics simulation analysis, which involves multiple physical phenomena.

AI breaks down the barriers of EV motor design, enabling full-vehicle optimization.

As for why he chose to focus on EV motors, he explains that “the technology is complex, making it well-suited for AI-driven optimization design. Also, from a competitive standpoint, with Chinese manufacturers and industry pioneers like Tesla, automakers’ need for motor design optimization is only increasing.” In addition, as motors are said to account for approximately half of the world’s electricity consumption, automakers are also looking forward to the societal impact of improving their efficiency, including saving energy and reducing CO2 emissions.

When it comes to designing electric motors and powertrains optimized for EVs, Rzepecki believes one major obstacle is “organizational silos.” As system complexity increases, engineering expertise becomes fragmented and isolated across internal departments, resulting in lower overall productivity.

Anser is not only capable of highly parallel processing, allowing thousands of simulations to be run simultaneously, according to Rzepecki, it also “breaks down the customer’s internal silos and utilises data across different domains, such as inverters and gearboxes, to achieve system-wide optimization of entire vehicles.”

Rzepecki’s vision for the future of engineering design

Rzepecki’s ambitions extend far beyond the design of EV motors and powertrains. Targeted applications range from industrial motors and wind-power generation systems to aerospace, drones, nuclear reactors, and even server cooling systems. “Our vision is to make optimization possible across all engineering design and to deliver value across a wide range of industries,” he emphasizes.

Articles in the same series

Latest Articles

-

IDEA INCUBATOR

Verification by "Going Beyond the Design”: Tenstorrent part 2

-

Takumi: The Height of Craft

Episode 5: Asahiyaki - Bridging the worlds of ceramic tea pottery and knives

-

IDEA INCUBATOR

Customization freedom with chiplets: Tenstorrent part 1

-

TRENDING TECH

Technology shaping our future: CES 2026 report

-

FEATURED CONTENT

Finding meaning in an engineering niche through passion, people, and culture

-

FEATURED CONTENT

Engineering wearable tech that expands human possibility