- Products

- Chemical Products

- Electrical/High Thermal Conductive Paste

- Ag Sintering Paste for Electrodes

Chemical Products

Ag Sintering Paste for Electrodes

Features and Applications of Ag Sintering Paste for Electrodes

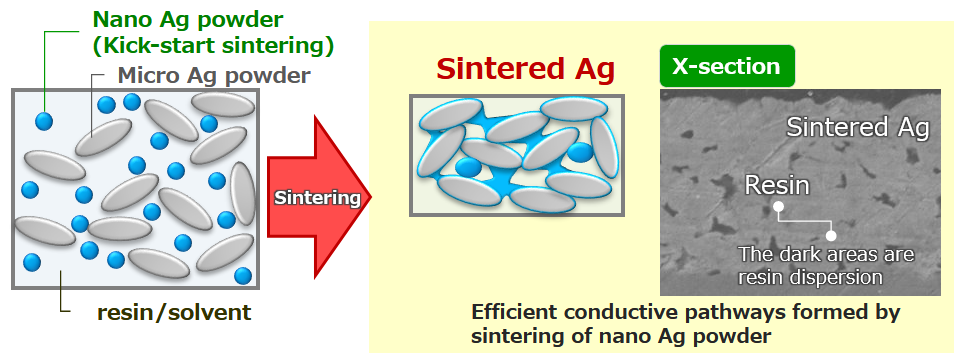

Our Ag sintering paste for electrodes achieves lower electrical resistance, lower ESR, and lower contact resistance in the product by utilizing sintering of nano-silver powder. It also adheres to non-metallic surfaces due to its resin composition.

Application image

Application Example: Metal-Based Power Inductor

Comparison of features with other materials

| Type of paste | KYOCERA Ag sintering |

Pure sintering | KYOCERA Ag paste |

Pb free solder |

|

| Composition |

Nano Ag powder |

Nano Ag powder |

Micro Ag powder |

Composite metal |

|

| Adhesion to | Metal | ++ | ++ | + | ++ |

| Non -Metal |

++ | - | ++ | - | |

| Electrical conductivity | ++ | ++ | + | ++ | |

Coating method

・Available lineup for dip coating and screen printing

・Customizable viscosity characteristics for required workability

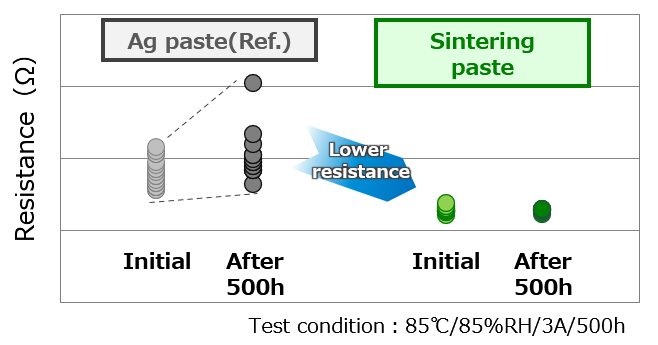

Interface Reliability Test (Trend of inductor resistance change)

・Lower electrical resistance than epoxy silver paste

・Low electrical resistance even after reliability test

Related Products