For improved accuracy in microelectronic component bonding and mounting

Dispensers are used in many manufacturing processes to inject controlled volumes of a liquid through a special nozzle. Kyocera's ceramic nozzles bring many advantages.

While conventional dispensing systems generally employ metal nozzles, replacing them with ceramic nozzles can improve both dispensing accuracy and long-term process stability.

Before replacing equipment or developing new dispensing materials/adhesives, Kyocera suggests that you consider improving process performance with ceramic nozzles.

Features

- High dispensing accuracy

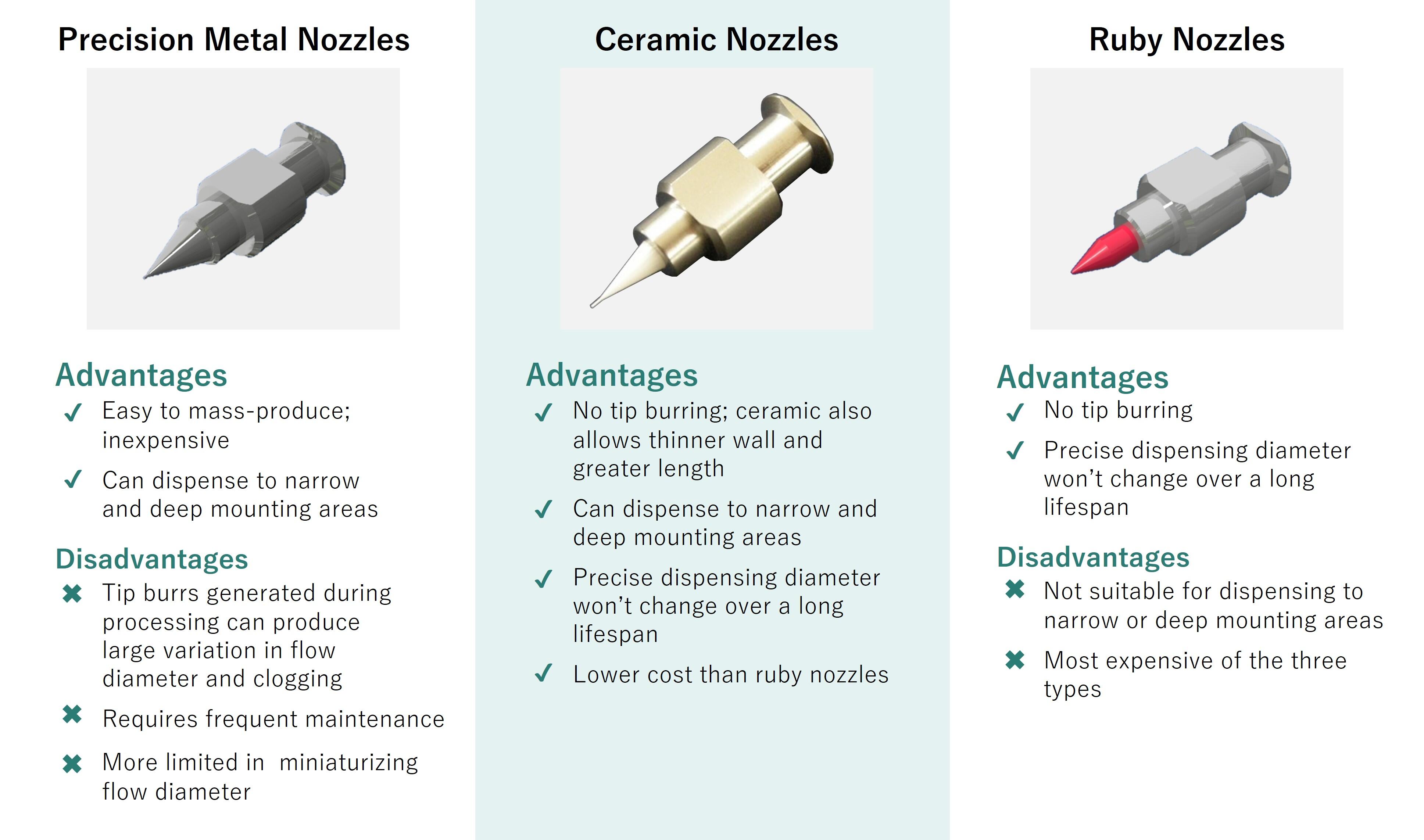

Compared to metal nozzles, ceramics virtually eliminate all burring at the tip during processing, which reduces clogging and variation in dispensing diameter

- Longer tip length (up to 3 mm) is possible

Enables dispensing to narrow or deep mounting areas

Dispenser Nozzle Types

Dispenser nozzles for bonding electronic components are typically made from three main materials: precision metal, ceramic, and ruby.

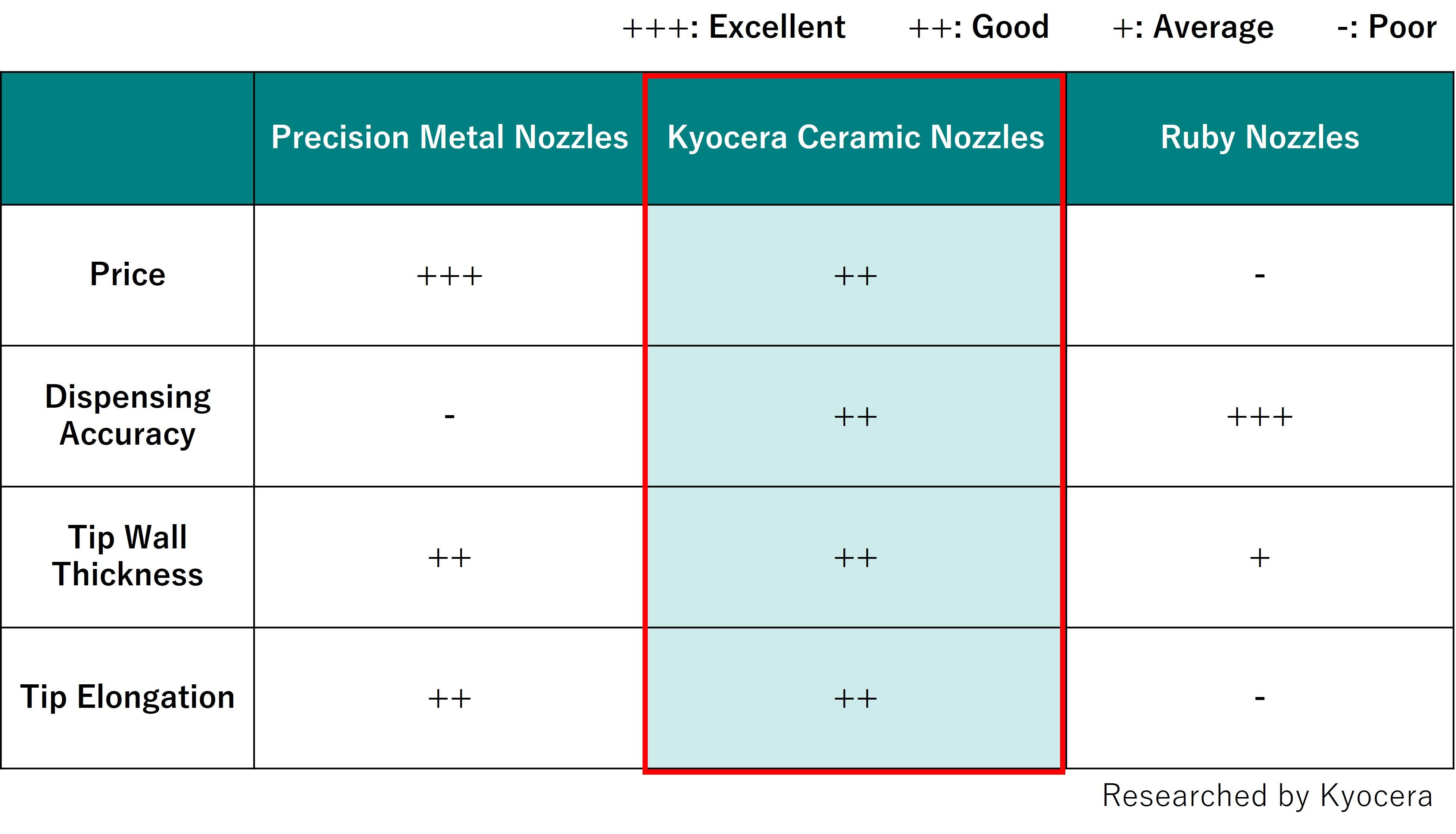

Comparison Chart by Material