Dispenser Nozzle Manufacturing Process

Introducing Kyocera's process for manufacturing dispenser nozzles.

Click here for dispenser nozzle product information.

1. Powder Mixing

Ceramic raw material powders and binders are mixed.

2. Pellet Formation

Mixed raw materials are formed into pellets.

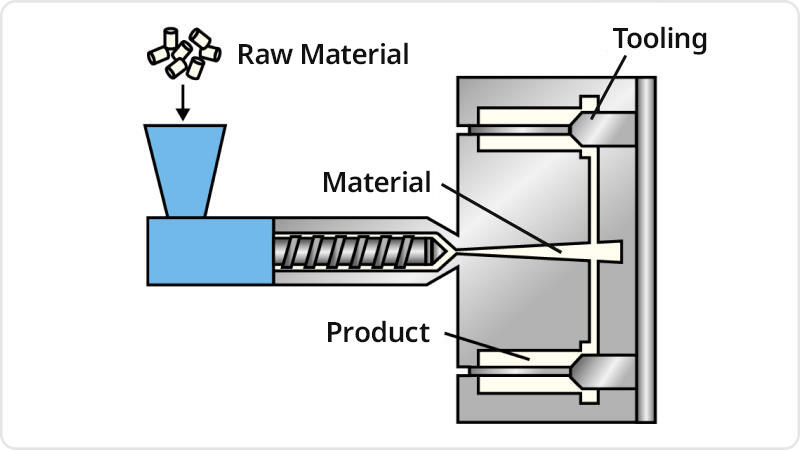

3. Injection Molding

Raw material pellets are melted and injected into the mold.

4. Firing

Molded units are hardened by firing at high temperatures.

5. Outer Diameter Finishing

Outer diameter is ground to precise dimensions.

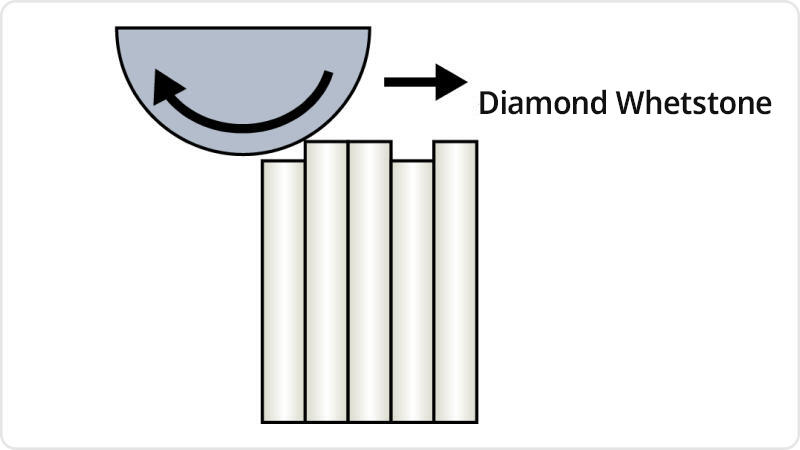

6. Length Finishing

Diamond whetstone finishes all units to a precise length.

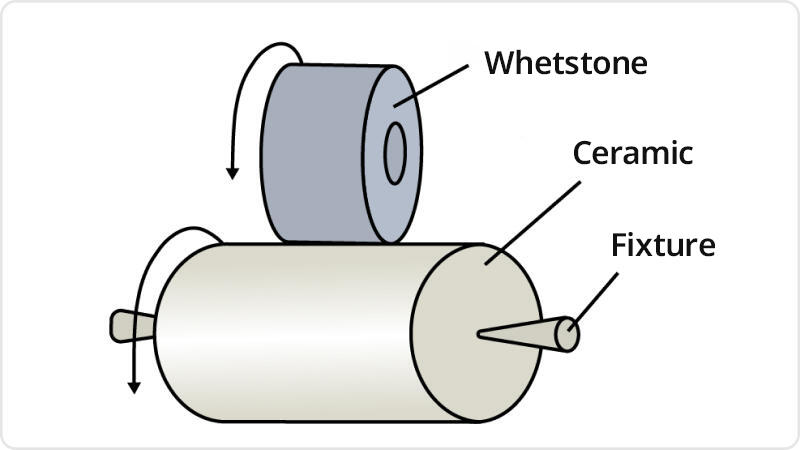

7. Concentricity Finishing

Ensures concentric inner and outer diameters.

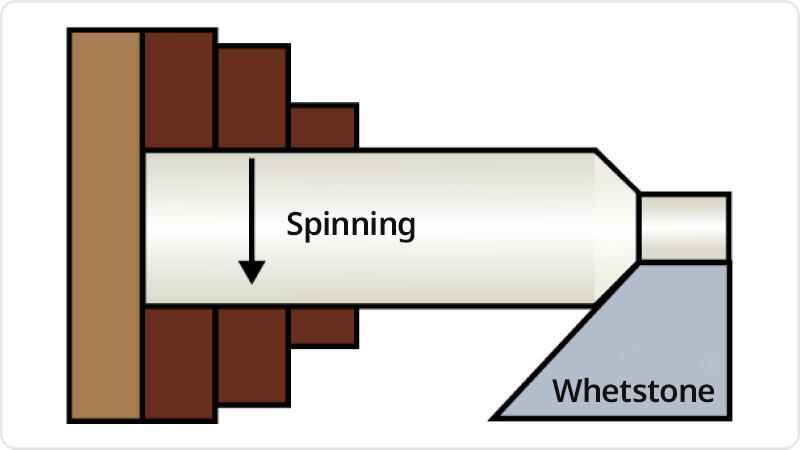

8. Tip Finishing

Tip shape and outer diameter are precisely machined.

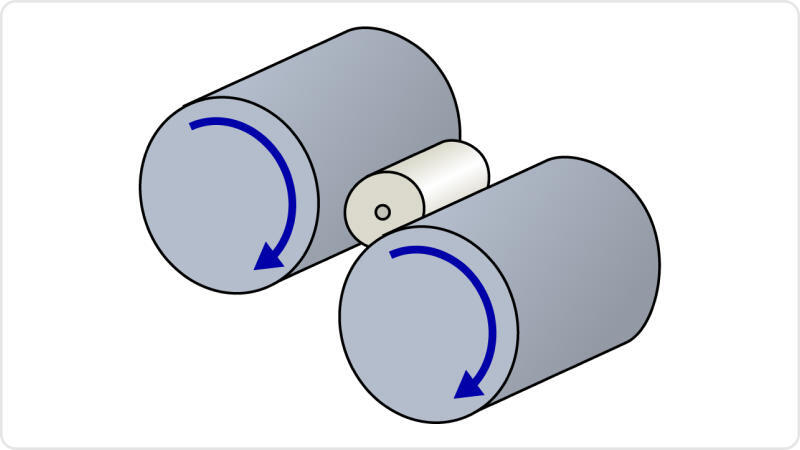

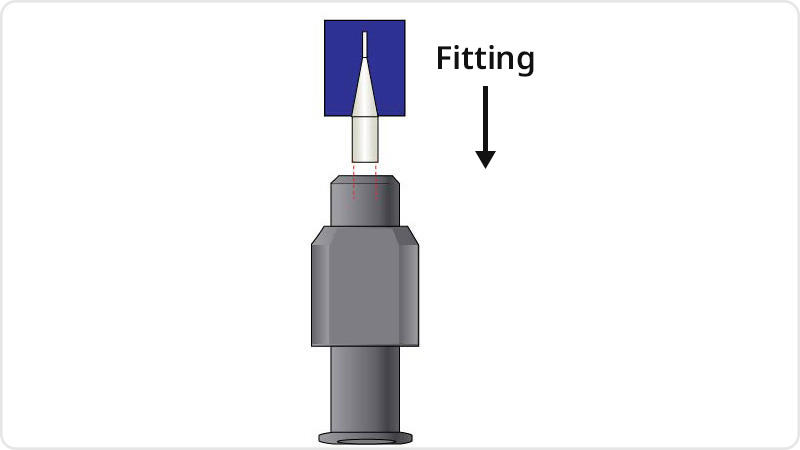

9. Press-Fitting

Ceramic part is pressed into a metal fitting to form a single piece.

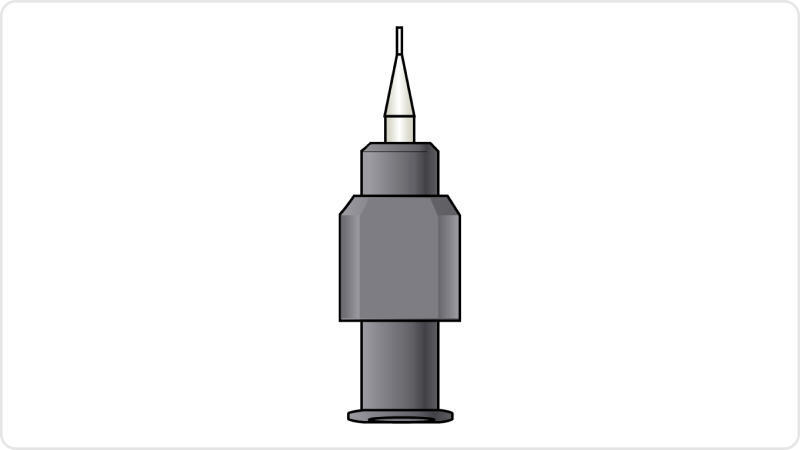

10. Visual Inspection / Shipping

Final product undergoes visual inspection before shipping.