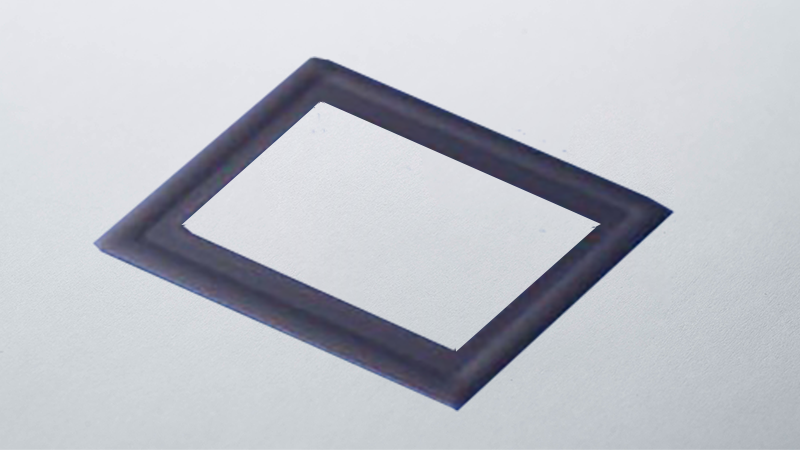

Window Lids for Image Sensors

Image sensors are widely deployed in cameras, smartphones, PCs, automobiles, drones, machine vision, and factory automation. These sensors are often encapsulated in ceramic packages; and, since many applications require a package with a window lid to satisfy challenging specifications, Kyocera offers window lids in a wide range of materials and technology options to meet your requirements.

Features

High-Reliability Thermosetting Resin

Hermetic Sealing

Material Options

Kyocera offers a wide selection of window materials to meet your requirements.

- Borosilicate glass

- Alkali-free glass

- Quartz glass

- Sapphire

- Synthetic quartz

- Silicon (optical grade)

- Germanium (optical grade)

Available in Extremely Precise Scratch-Dig Specifications

Kyocera’s window lids for high-end image sensors are available with scratch-dig specifications as low as 10µm-8µm*.

This tolerance is equivalent to maximum imperfection the size of a coin on a flat surface the size of a baseball field. Kyocera window lids that meet this tight specification undergo rigorously controlled manufacturing and inspection processes.

Tolerance depends on the material. Contact us for details.

Custom Optical Characteristics

Kyocera offers window materials and optical designs to suit your application.

Below are some examples of customization.

Contact us for details.

Example 1

Matching the coefficient of thermal expansion (CTE) between the package and window lid is necessary for reliable sealing.

⇒Borosilicate glass has a CTE close to that of alumina ceramic. Special coatings are added for custom optical requirements.

Example 2

Changing the incident angle generally creates a shift in optical characteristics (waveform) and color.

⇒Kyocera can provide IR cut coatings that minimize this shift.

Example 3

Ultraviolet and near-infrared image sensors require good transmittance of the required wavelength band to achieve accurate sensing and imaging.

⇒Optimal lids can be designed by choosing the right material and optical coatings.

Example 4

Infrared image sensors require good transmittance of the required IR wavelength band for accurate sensing and imaging.

⇒Optimal lids can be designed by choosing the right material and optical coatings.

Other Options

High-Reliability Thermosetting Resin

Glass lids can be supplied with sealing material attached, eliminating a process step in high-mix, low-volume production.

Kyocera offers fast-curing resins to minimize the impact on sensor elements and stress-relieving resins to reduce the thermal mismatch between the package and lid.

Contact us for details.

Flare-Reducing Automotive Optical Glass Lids

- Sealing resin serves as a light-shielding film to avoid unwanted light.

- Offers advantages over other light-shielding concepts

Eliminates metal light-shielding plate for lower profile while also eliminating plate-attachment process.

Please see details below.